Smashing device for alloy material

A technology of alloy material and crushing device, applied in grain processing and other directions, can solve problems such as insufficient crushing effect and inability to meet, and achieve the effect of solving incomplete crushing, convenient collection and good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

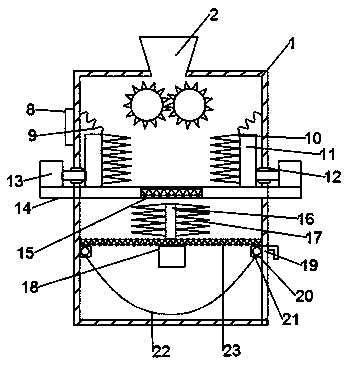

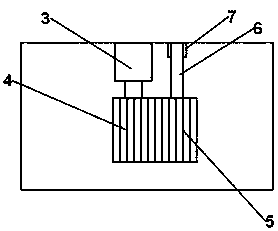

[0022] see Figure 1~2 In an embodiment of the present invention, a crushing device for alloy materials includes a device main body 1, a feed port 2, a receiving plate 14, a second motor 18, and a hinged door 19. The top of the device main body 1 is provided with an inlet Feed port 2, raw materials are added through the feed port 2, a first motor 3 is fixedly connected above the inner surface of the rear wall of the main body 1 of the device, and the front end of the output shaft of the first motor 3 is movable with the first roller 4 connected, the right end of the first roller 4 is provided with a second roller 5 that engages with each other, and the second roller 5 is movably arranged at the front end of the first rotating rod 6, and the rear end of the first rotating rod 6 It is rotatably connected with the first bearing 7 , and the first bearing 7 is fixedly arranged on the inner surface of the rear wall of the device main body 1 .

[0023] Preferably, the first motor 3 ...

Embodiment 2

[0030] A kind of alloy material processing equipment comprises the crushing device for alloy material as described in embodiment 1.

[0031] The working principle of the present invention is: the first motor 3 is connected to the external 220V voltage through a wire, the first motor 3 works to drive the first roller 4 to rotate, and the first roller 4 and the second roller 5 mesh with each other to drive the second roller The wheel 5 rotates to achieve the first step of crushing. The upper ends of the two extrusion plates 11 are fixedly connected to one end of the elastic cloth 9, and the other end of the elastic cloth 9 is fixedly connected to the inner wall of the device main body 1 to prevent the raw material from being crushed. The raw material falls between the two extruding plates 11, and the hydraulic cylinder 13 works to drive the two extruding plates 11 to move, thereby extruding the raw materials into vermicelli, further improving the crushing effect, and the output s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com