Shovel plate belt guide device

A technology for shoveling plates and belts, which is applied in the field of strip leader devices, can solve the problems of increasing the labor load and labor intensity of operators, reducing production efficiency, and affecting the smooth progress of threading, so as to improve the efficiency of threading and reduce human intervention , the effect of reducing security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

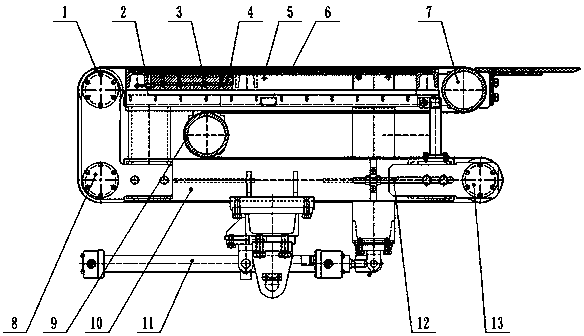

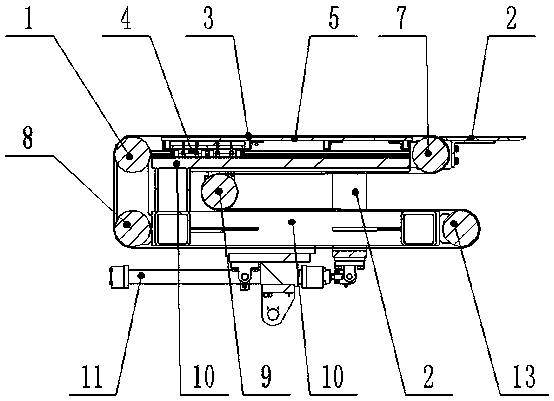

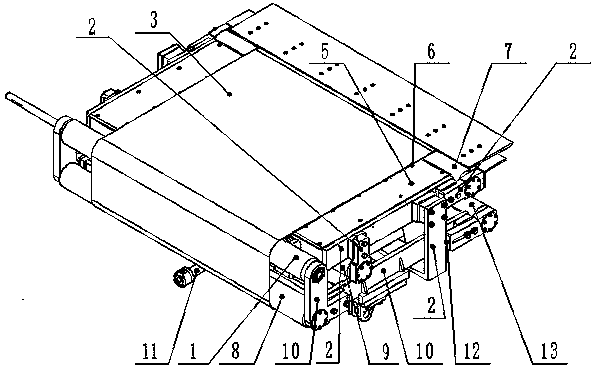

[0013] Such as figure 1 , figure 2 , image 3 Shown, conveying belt 3 of the present invention is wound on driving roller 1, driven roller one 7, driven roller two 8, driven roller three 9, driven roller four 13, driving roller 1, driven roller two 8, The driven roller four 13 is installed on the fixed bracket 10, and the belt tensioning device 12 is installed on the fixed bracket 10; 17. The driven roller three 9 is fixed on the sliding shovel plate 2; the nylon plate 5 mounted on the fixed bracket 10 is equipped with a powerful magnet 6, and there are multiple powerful magnets 6, which are evenly placed on the nylon plate 5, and the nylon plate 5 There is a gap between the conveyor belt 3 so that the conveyor belt 3 can run smoothly; the cylinder body of the telescopic oil cylinder 11 is connected with the fixed bracket 10, and the piston rod of the telescopic oil cylinder 11 is connected with the sliding shovel 2.

[0014] The piston rod of the telescopic oil cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com