Elbow pipe double-end welding groove machining tool

A technology for welding grooves and elbows, applied in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve the problems of large workshop area, occupancy waste, large limitations, etc., and achieve the effect of saving workshop area occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

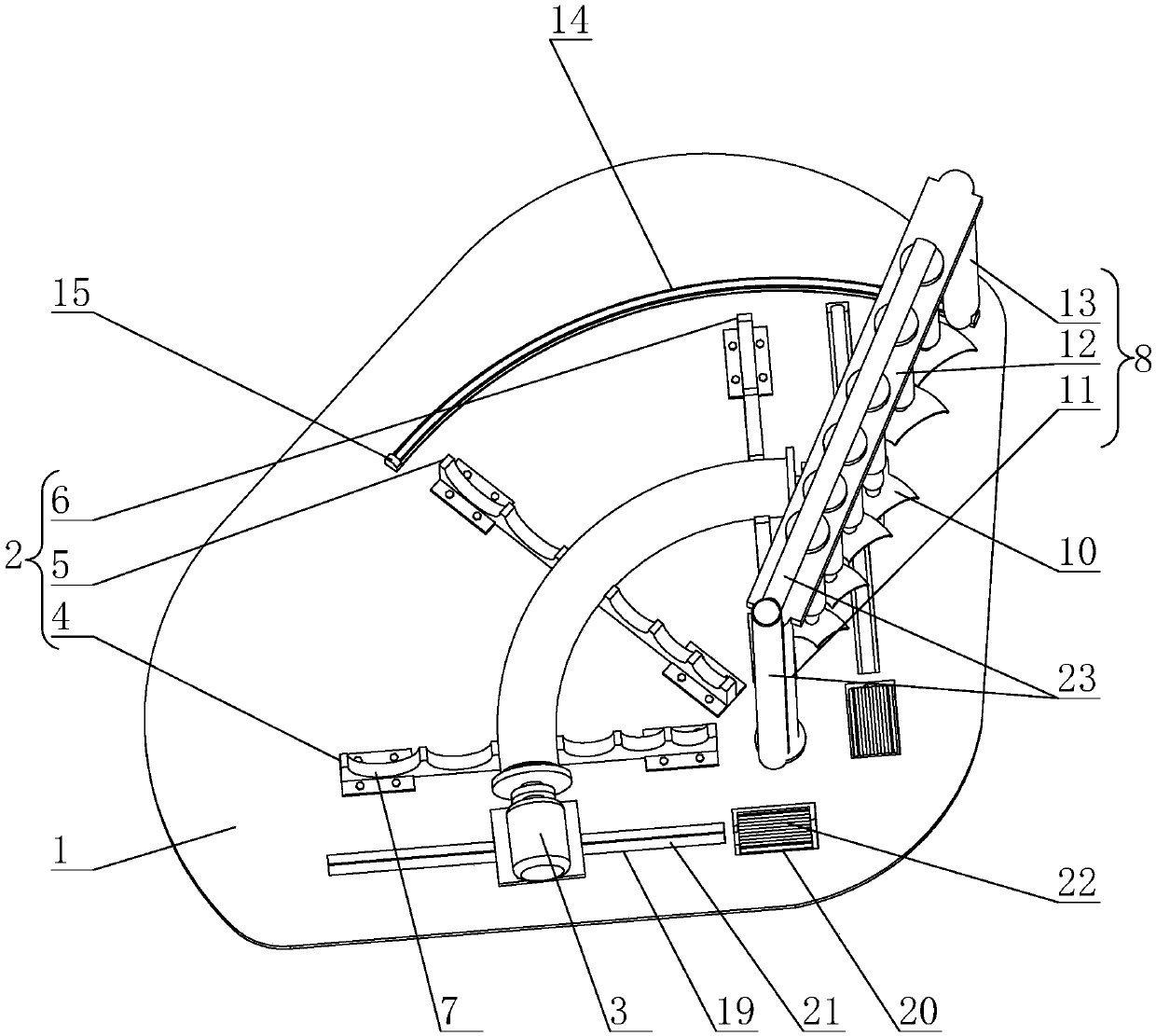

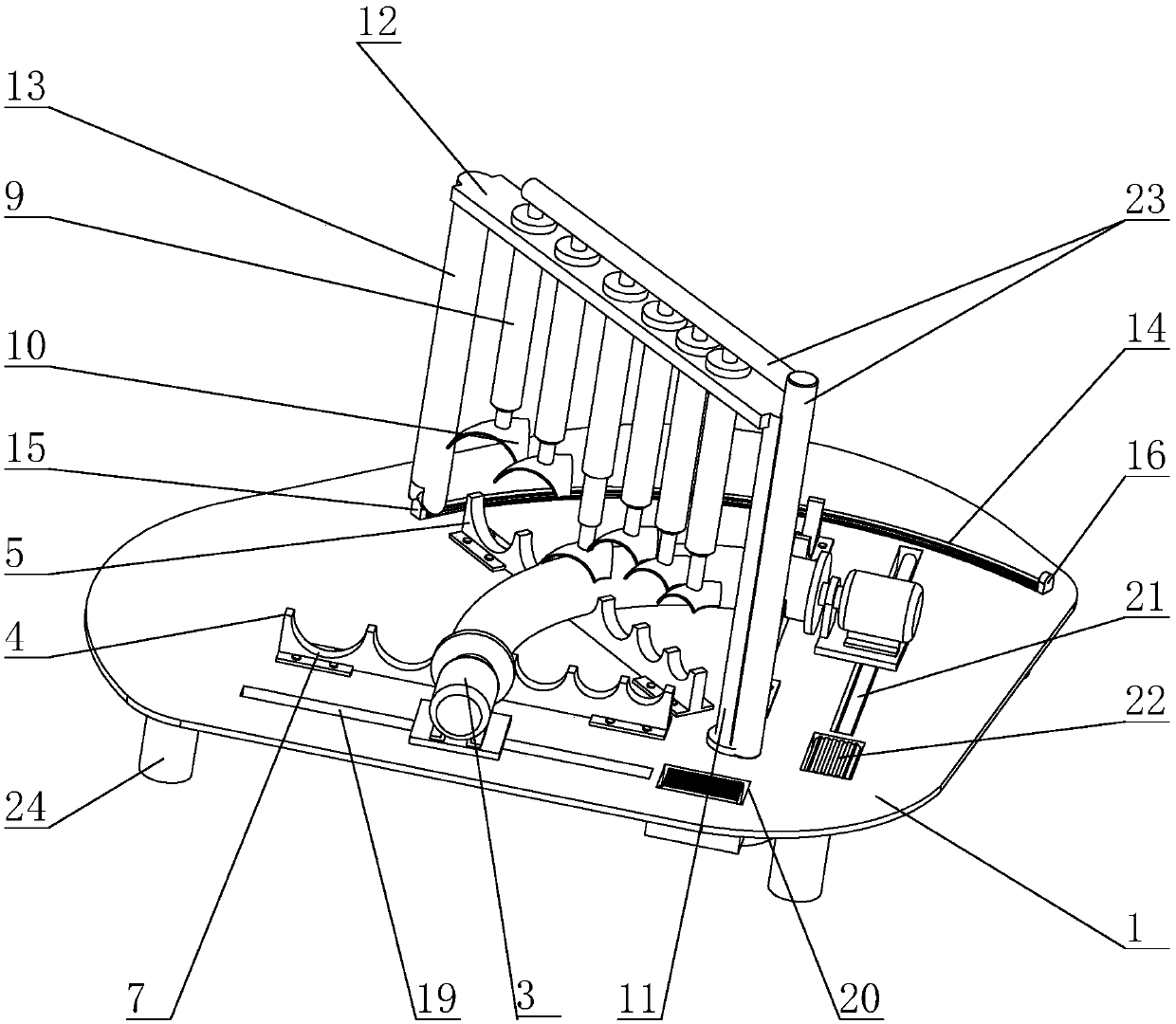

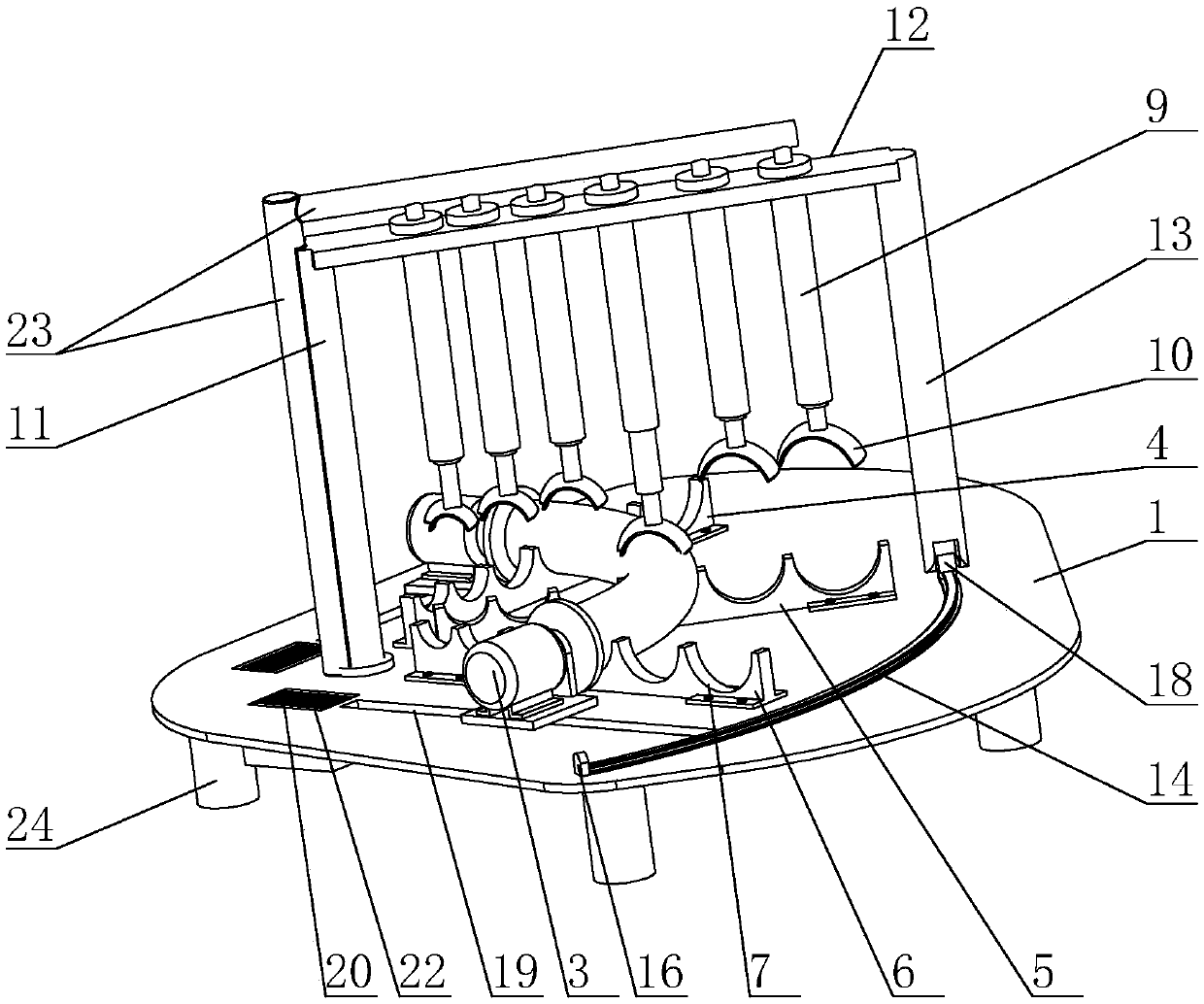

[0028] The present invention is a tooling for bevel double-head welding bevel processing. The main structure includes a worktable 1, a bend support 2, a pressing device and a beveling machine 3; the bend support 2, a pressing device And the beveling machine 3 are both set on the workbench 1. The elbow supports 2 are provided with three on the workbench 1, namely the left port support 4, the middle support 5 and the right port support 6. A plurality of curved seat openings 7 are provided on the elbow support 2. As shown in the drawings in the specification, the left port support 4, the middle support 5, and the right port support 6 jointly place the elbow workpiece to be processed, and the elbow workpiece is placed on the cambered seat opening 7.

[0029] As shown in the accompanying drawings in the specification, the elbow support 2 is provided with a plurality of arc-faced sockets 7 of different diameters, and each arc-faced socket 7 corresponds to a different elbow model; this ...

Embodiment 2

[0038] Compared with embodiment 1, in this embodiment 2, a driving wheel 18 is provided at the bottom of the moving column 13 and the driving wheel 18 is driven by a hub motor. In the second embodiment, the rotatable opening and closing drive of the portal frame 8 is realized by the rotation of the driving wheel 18 driven by the hub motor, and the movement direction is controlled by controlling the forward and reverse rotation. The rest of the structure and the connection relationship between the structures in the second embodiment are the same as those in the first embodiment.

Embodiment 3

[0040] Compared with embodiment 1, in this embodiment 3, there are multiple beveling machines 3, and the left port support 4 and the right port support 6 are both provided on the outside. The number is the same, so that each beveling machine 3 on a single side corresponds to a camber seat 7 to process one type of elbow workpiece. In this way, during use, it is no longer necessary to adjust the position of the beveling machine 3 according to the actual situation, and it is no longer necessary to adjust the tool on the processing cutter head of the beveling machine 3 according to the actual situation. The rest of the structure and the connection relationship between the structures in the third embodiment are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com