Assembly system based on visual guidance

An assembly system and vision-guided technology, applied in the parts of TV systems, parts of color TVs, TVs, etc., can solve problems such as accidents affecting product quality, difficulty in meeting assembly tasks, missing parts, and reduce work experience. Requirements, simple operation method, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

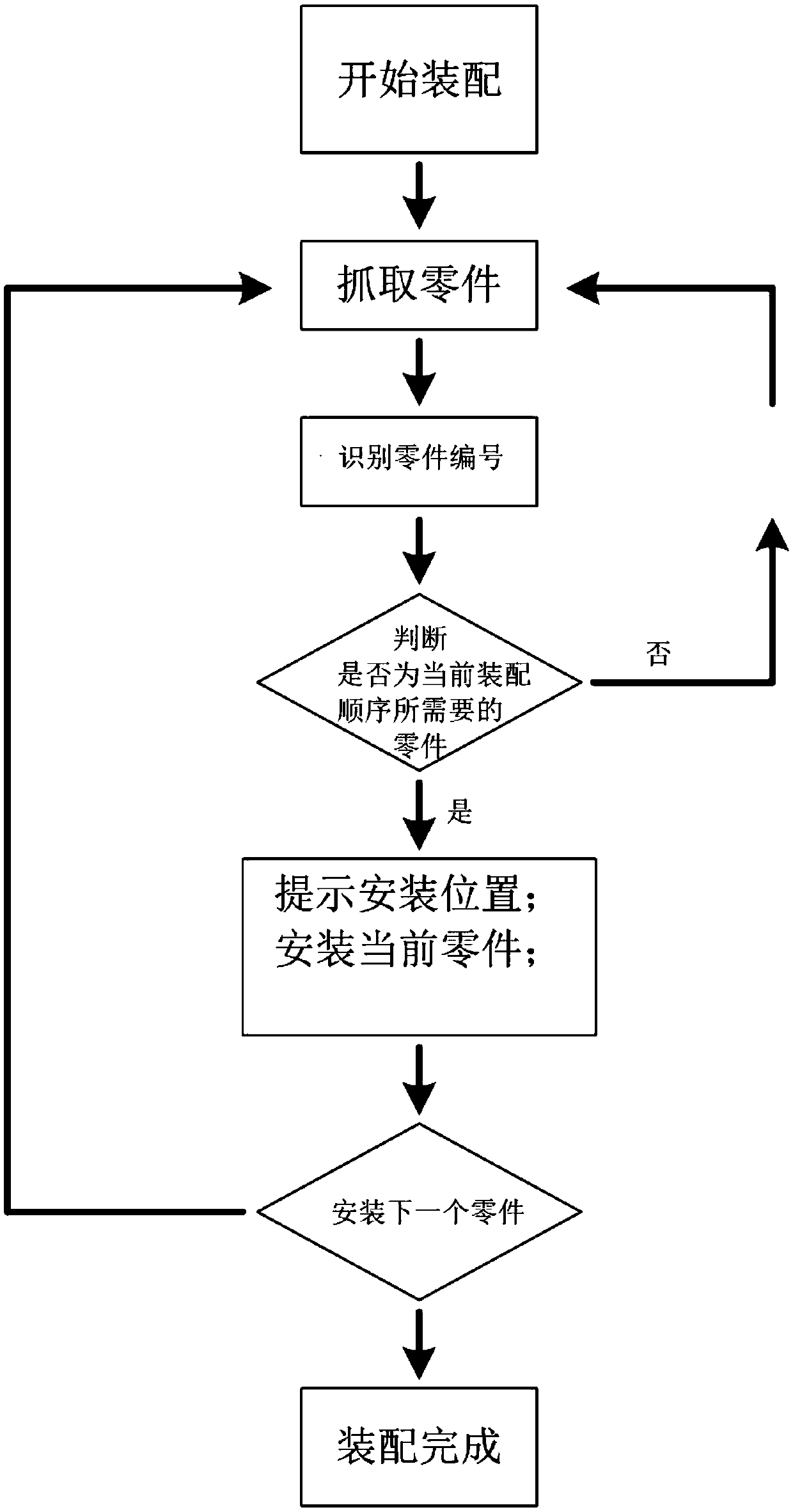

[0021] The present invention will be described in detail below with reference to the accompanying drawings and examples.

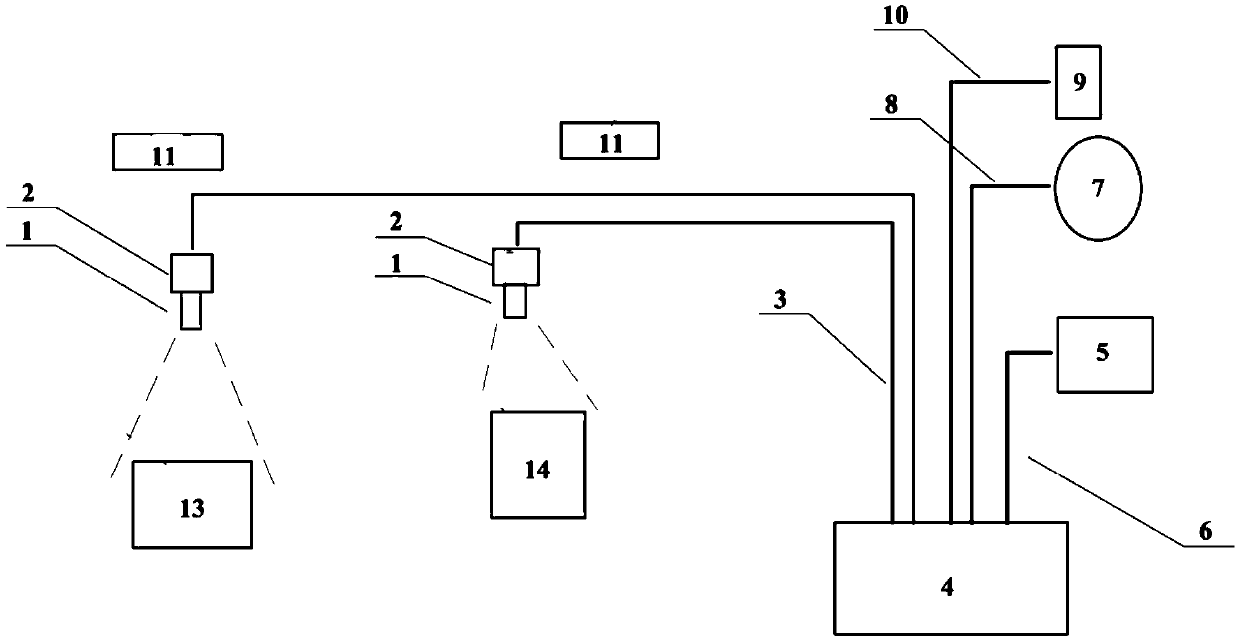

[0022] This embodiment provides an assembly system based on visual guidance, see the attached figure 1 , including: two video signal acquisition units, a control unit 4, a display unit 5, a voice broadcast unit 7, an alarm indicator light 9 and a light source 11;

[0023] The two video signal acquisition units are respectively used to collect the video information of the parts 13 and the assembly 14 to be installed currently, and convert the video information into electrical signals, and send them to the control unit 4 through the video signal line 3 respectively; Wherein, each video signal acquisition unit includes an industrial camera 2 and an industrial lens 1 matched therewith; the industrial camera 2 adopts a high-definition camera with a resolution of 5 million pixels;

[0024] After the control unit 4 performs intelligent image algorithm processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com