Rubber injection cold runner design and optimization method

A technology of rubber injection and optimization method, applied in the field of design and optimization of rubber injection cold runners, can solve problems such as low molding efficiency, high operating intensity, uneven quality, etc., and achieve good applicability, high reliability, and short cycle times. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

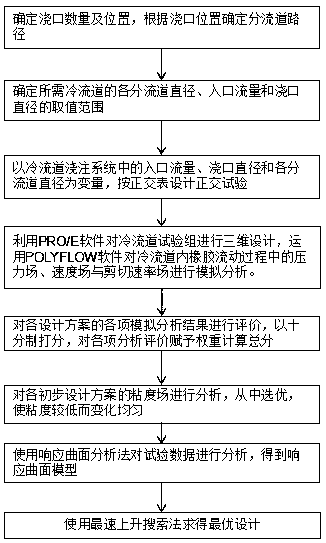

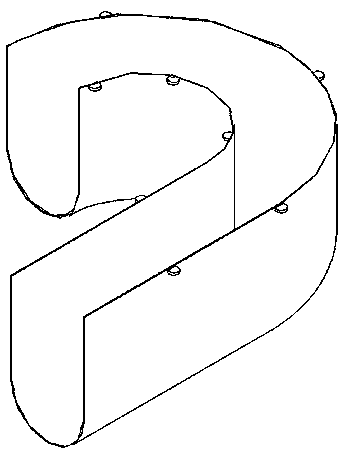

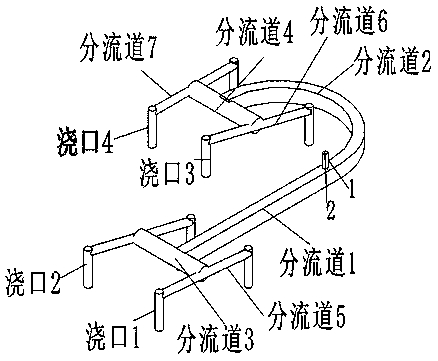

[0040] Such as Figure 1-4 , a rubber injection cold runner design and optimization method, comprising the following steps:

[0041] Step 1, with the help of the cold runner gating system, the cold runner gating system includes a main channel 1, an inlet 2 arranged on the upper end of the main channel 1, a runner 3 connecting the inlet to the outlet of the main channel 1, and an outlet of the corresponding runner 3 Connected gate 4; first, select the rubber product to be formed; then, perform three-dimensional modeling on the rubber product; secondly, determine the number and position of the gate according to the required rubber product parameters; thirdly, determine the gate position according to the gate position runner path;

[0042] Step 2, first, under the premise that the pressures at the gates of the step 1 are equal, the diameter of each runner is preliminarily determined through the fluid motion equation;

[0043] Step 3, determine the value range of the inlet flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com