A kind of tpu high and low temperature film composite mesh cloth and preparation method thereof

A technology of high and low temperature film and mesh cloth, which is applied in the field of TPU high and low temperature film composite mesh cloth and its preparation, can solve the problems of harsh use conditions, easy water ingress, mesh deformation, etc., and achieve increased adhesive performance, improved peel strength, The effect of improving T softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

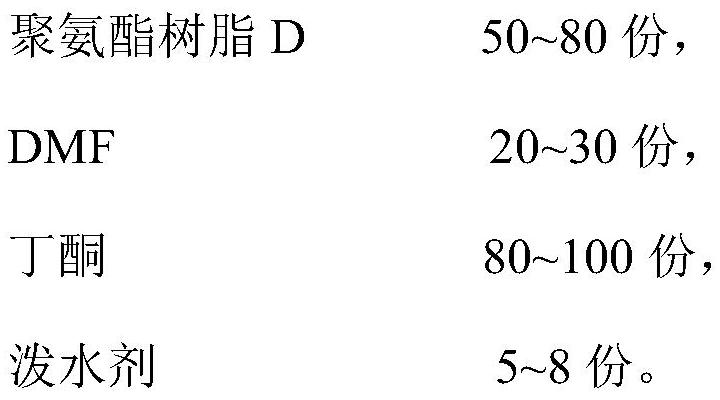

[0040] The components used in the polyurethane surface layer, the middle layer, the adhesive layer and the polyurethane slurry used for mesh pretreatment in this embodiment, the amount of the components and the source of the manufacturer of the components are shown in Table 1.

[0041] Table 1

[0042]

[0043] The preparation process of the TPU high and low temperature membrane composite mesh cloth in this embodiment is as follows:

[0044] a. Coating the polyurethane surface layer slurry (the cutter head gap is 15 wires) on the surface of the release paper, and place it at 120 ℃ for heating and drying to form the polyurethane surface layer; coat the polyurethane middle layer slurry (the cutter head gap is 15 15 wires) on the surface layer, heated and dried at 120°C to form a polyurethane middle layer; coat the polyurethane adhesive layer slurry (the gap between the blades is 18 wires) on the middle layer coating, and place it in an oven at 120°C , forming a polyurethane ...

Embodiment 2

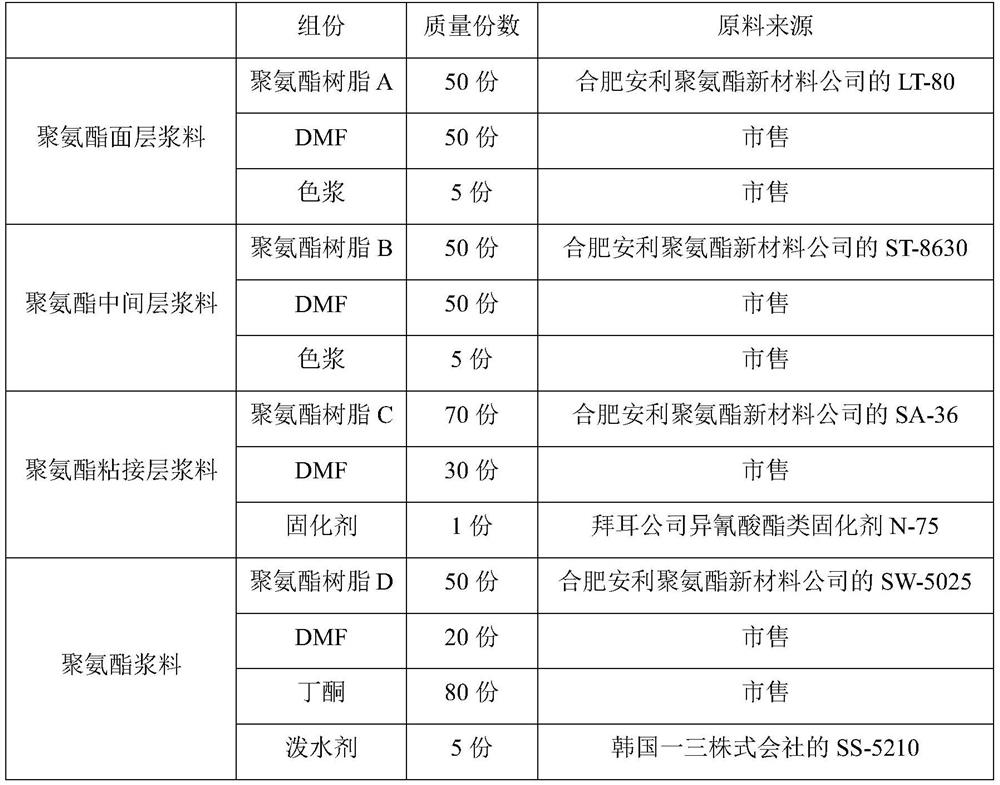

[0050] In this embodiment, the components used in the polyurethane surface layer, the middle layer, the adhesive layer and the polyurethane slurry for mesh pretreatment, the amount of the components and the source of the manufacturer of the components are shown in Table 2.

[0051] Table 2

[0052]

[0053] The preparation process of the TPU high and low temperature membrane composite mesh cloth in this embodiment is as follows:

[0054] a. Coating the polyurethane surface layer slurry (the cutter head gap is 20 wires) on the surface of the release paper, and place it at 135 ℃ for heating and drying to form the polyurethane surface layer; coat the polyurethane middle layer slurry (the cutter head gap is 20 20 filaments) on the surface layer, heated and dried at 140°C to form a polyurethane middle layer; coat the polyurethane adhesive layer slurry (with a blade gap of 25 filaments) on the middle layer coating, and place in an oven at 125°C , forming a polyurethane adhesive la...

Embodiment 3

[0060] The components used in the polyurethane surface layer, the middle layer, the adhesive layer and the polyurethane slurry used for mesh pretreatment in this embodiment, the amount of the components and the source of the manufacturer of the components are shown in Table 3.

[0061] table 3

[0062]

[0063] The preparation process of the TPU high and low temperature membrane composite mesh cloth in this embodiment is as follows:

[0064] a. Coating the polyurethane surface layer slurry (cutter gap is 18 wires) on the surface of the release paper, place 130 ℃ heating and drying to form polyurethane surface layer; coat the polyurethane middle layer slurry (cutter gap is 18 wires) 18 filaments) on the surface layer, heat and dry at 130°C to form a polyurethane middle layer; coat the polyurethane adhesive layer slurry (the gap between the blades is 20 filaments) on the middle layer coating, and place it in an oven at 122°C , forming a polyurethane adhesive layer;

[0065]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com