Accumulated water removing device for pneumatic material conveying system

A technology of pneumatic transmission and cleaning device, used in transportation and packaging, transportation of bulk materials, conveyors, etc., can solve the problems of difficult maintenance, difficult cleaning and maintenance, time-consuming and labor-intensive, etc., to ensure transportation efficiency, improve work efficiency, Simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

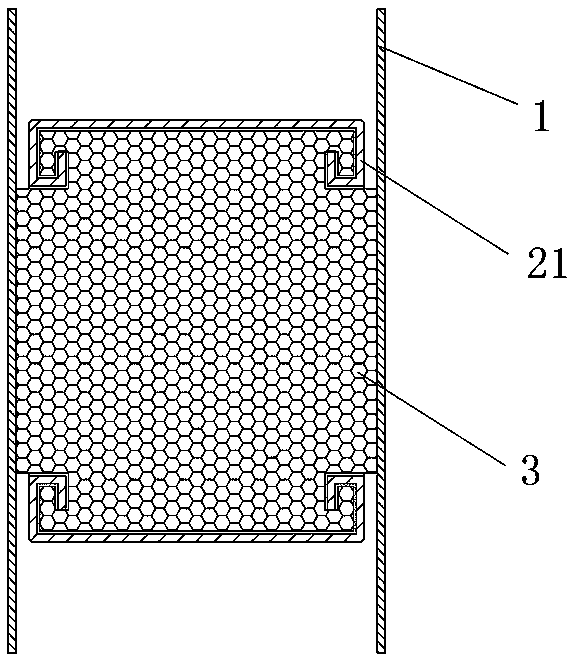

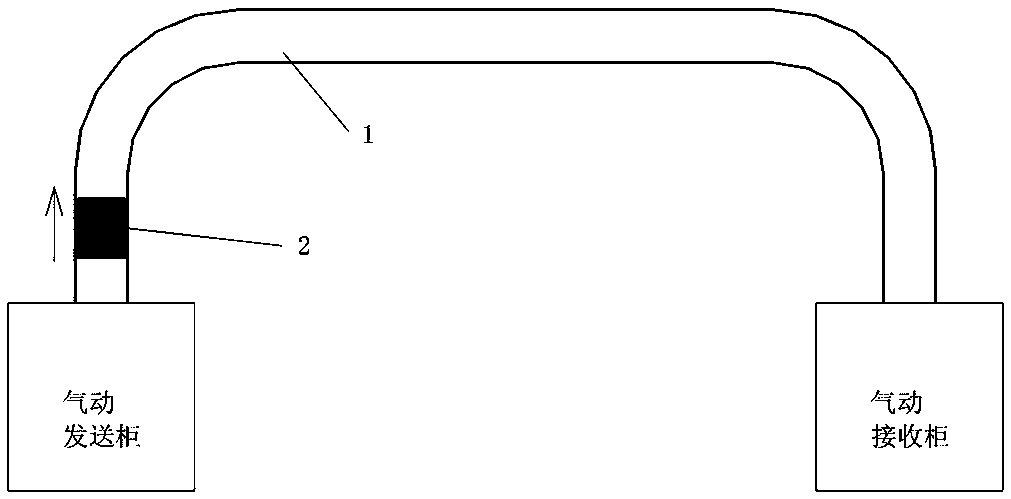

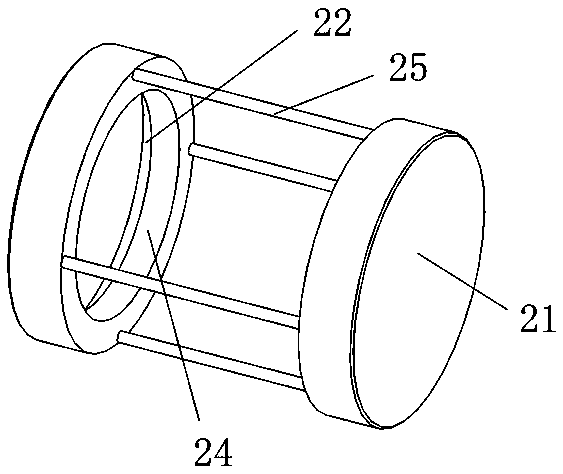

[0035] Such as Figure 1 to Figure 8 As shown, the present invention provides a water accumulation device for a material pneumatic conveying system, comprising a moving body 2 that can be pneumatically conveyed in a pneumatic conveying pipeline 1, and the length of the moving body 2 is not longer than 2 meters. The mobile body 2 is provided with an adsorbent 3 made of water-absorbing material (such as sponge, asbestos adsorbent material, etc.), and when the mobile body 2 is transported, the adsorbent 3 is in contact with the inner wall of the pneumatic transmission pipeline 1 to absorb moisture on the inner wall . The specific implementation principle is as follows:

[0036] When there are temperature changes, air compression, etc., or when the operator thinks it needs to be cleaned, the accumulated water cleaning device can be directly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com