Corrosion-resistant steel for gondola for coal transportation with yield strength of 550mpa and its manufacturing method

A technology of yield strength and manufacturing method, applied in the field of steel for railway vehicles, can solve the problems of high cost, poor welding and formability, and corrosion resistance that does not meet the requirements, so as to improve the corrosion resistance of medium and reduce vehicle maintenance. cost, the effect of improving the operating life

Active Publication Date: 2020-05-29

ANGANG STEEL CO LTD

View PDF20 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] Aiming at the technical problems existing in the production of steel used in the current gondola for coal transportation, such as: the use of aluminum alloy and stainless steel is relatively expensive, the welding and formability are not good, and the corrosion resistance of the existing steel cannot meet the requirements, the invention is proposed. Technical solutions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

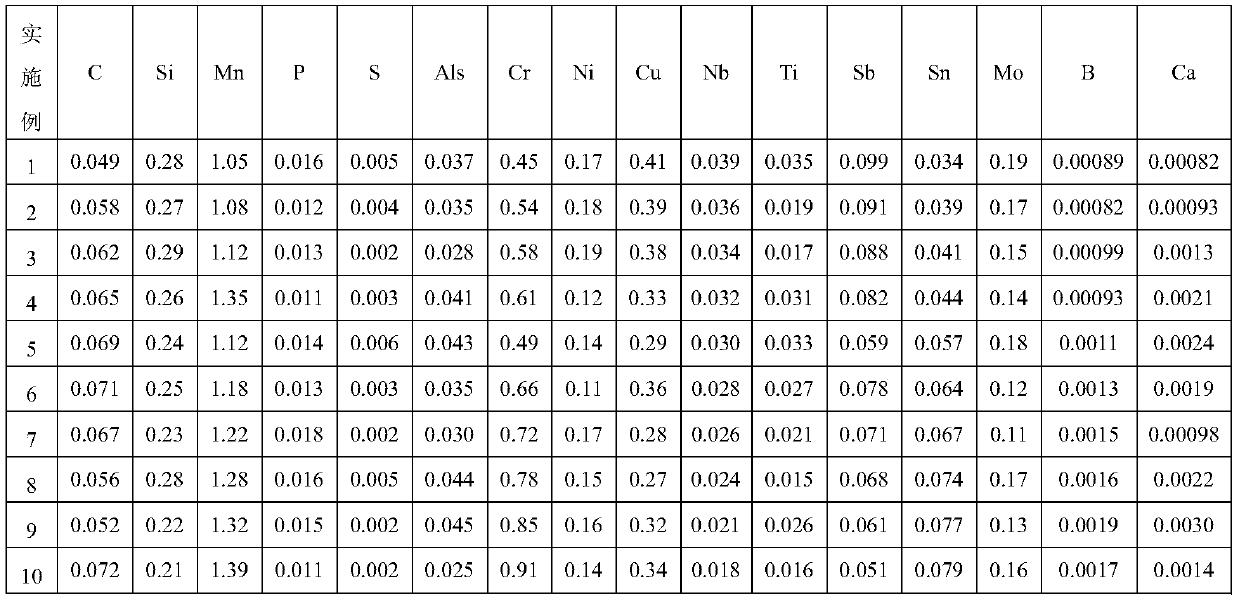

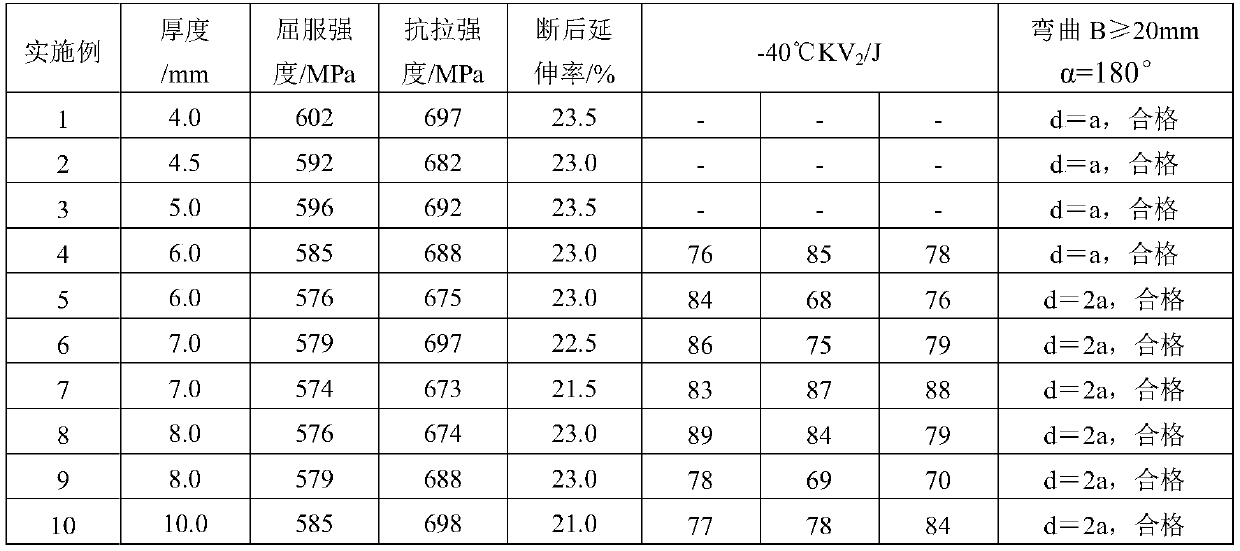

[0034] The following examples are used to specifically illustrate the contents of the present invention, and these examples are only general descriptions of the contents of the present invention, and do not limit the contents of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a corrosion-resisting steel with yield strength of 550 MPa for a coal open-boxcar and a manufacturing method thereof. The corrosion-resisting steel is prepared from 0.049%-0.072% of C, 0.21%-0.29% of Si, 1.05%-1.39% of Mn, less than or equal to 0.018% of P, less than or equal to 0.006% of S, 0.015%-0.045% of Als, 0.45%-0.91% of Cr, 0.11%-0.19% of Ni, 0.27%-0.41% of Cu, 0.018-0.039% of Nb, 0.015%-0.035% of Ti, 0.046%-0.099% of Sb, 0.034%-0.079% of Sn, 0.11%-0.19% of Mo, 0.0008%-0.0019% of B, 0.0008%-0.0030% of Ca, and the balance Fe and inevitable impurities. The methodincludes steps of heating a plate blank being 135-170 mm thick to the temperature of 1228-1249 DEG C, rough rolling the plate blank at the temperature greater than 1100 DEG C, finish rolling the plateblank at the temperature of 1000-1100 DEG C, carrying out final rolling on the plate blank at the temperature of 830-895 DEG C, and coiling the plate at the temperature of 580-650 DEG C. The steel plate has excellent resistance to sulfuric acid and chloride ion corrosion.

Description

technical field [0001] The invention belongs to the field of steel for railway vehicles, and relates to a corrosion-resistant steel suitable for use in a corrosion environment containing acidic medium and chloride ions and a manufacturing method thereof. Background technique [0002] Ordinary steel gondola cars are usually only subject to atmospheric corrosion, while coal transport gondola cars are attacked by a rather harsh corrosive environment. First of all, coal contains sulfides that have a strong chemical corrosion effect on steel; moreover, because water is used to shock coal during mining, the coal contains water, and when coal is transported in winter, certain salts must be added to prevent freezing. In order to lower the freezing point, this brings extremely corrosive chloride ions. [0003] At present, the manufacturing materials used for coal transport gondolas are aluminum alloy, stainless steel or traditional weathering steel. Although aluminum alloy and stai...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/02C22C38/04C22C38/06C22C38/42C22C38/48C22C38/50C22C38/60C22C38/44C22C38/54C21D8/02

CPCC21D8/0226C22C38/008C22C38/02C22C38/04C22C38/06C22C38/42C22C38/44C22C38/48C22C38/50C22C38/54C22C38/60

Inventor 刘志伟张瑞琦孙傲郭晓宏高磊杨玉金星王洪海景鹤王鑫

Owner ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com