Fabricated steel-frame structure joint

A technology of structural nodes and steel frames, which is applied in the direction of building structure and construction, can solve the problems of occupying a lot of labor resources, increasing the overall cost, and widespread construction waste, so as to reduce labor intensity, shorten the construction period, and achieve high construction quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

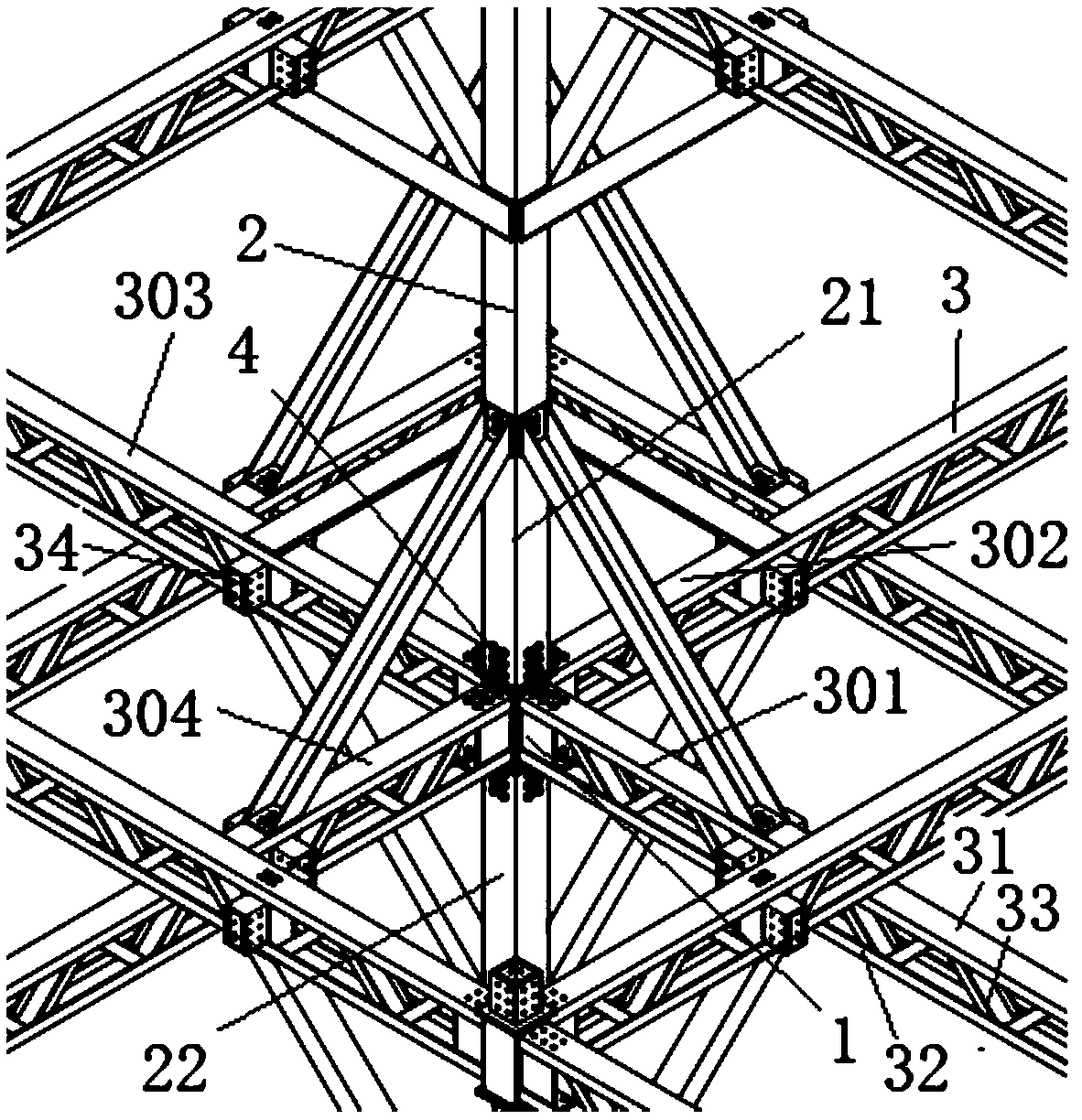

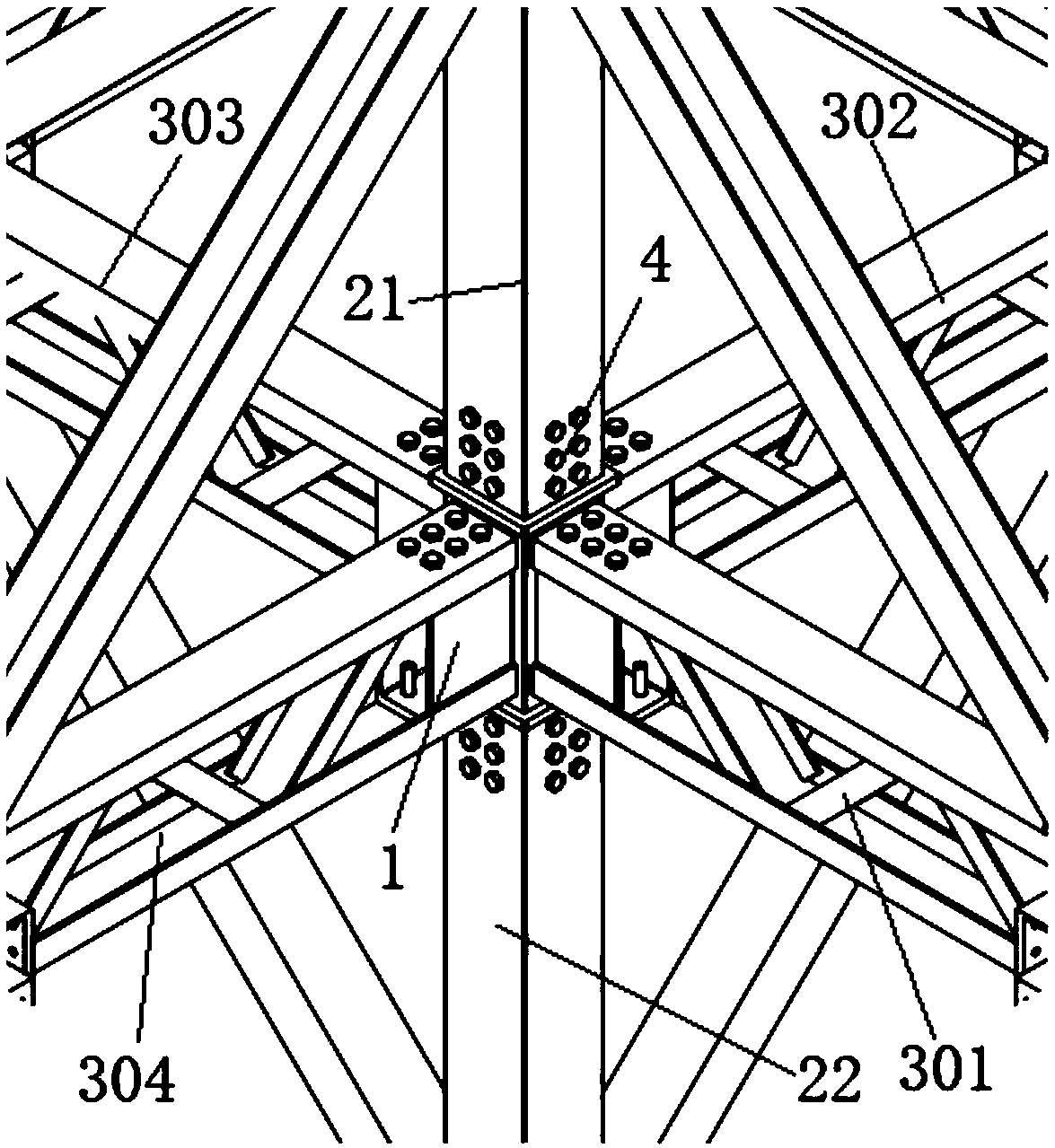

[0040] Reference attached Figure 1-7 As shown, in Embodiment 1 of the present invention, a middle node of an assembled steel frame structure includes a middle node core 1, a box column 2, a truss frame beam 3 and self-tapping bolts 4; the middle node core 1 is connected with the box column 2 and the Truss frame beam 3 connection;

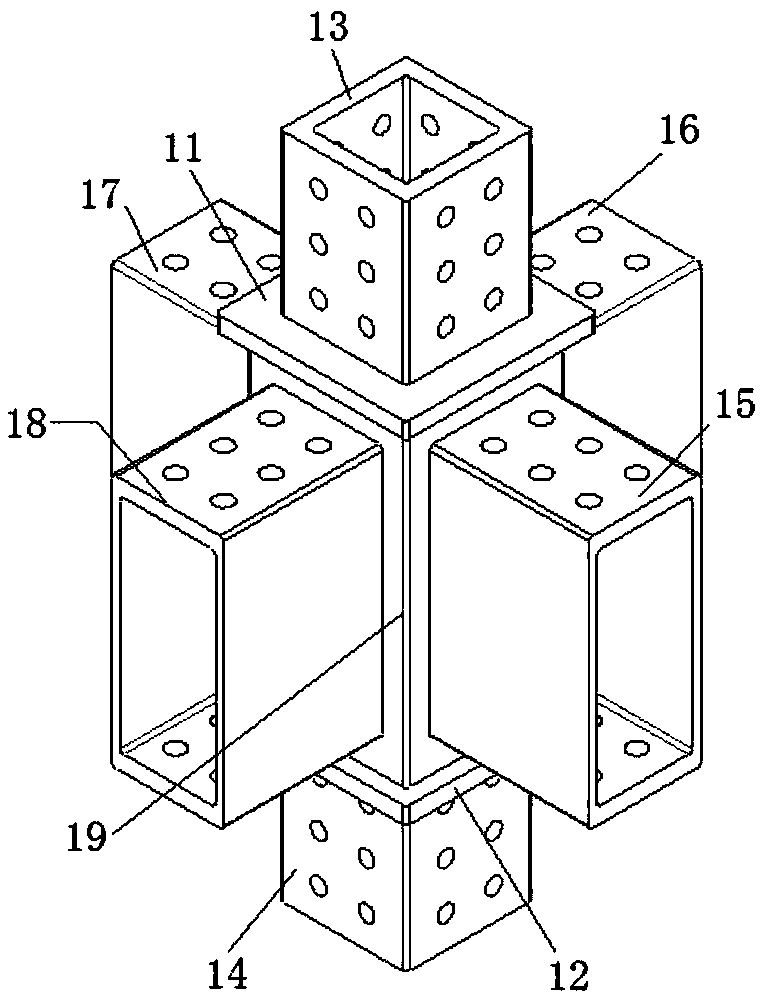

[0041]The middle node core 1 includes an upper end plate 11, a lower end plate 12, an upper end joint 13, a lower end joint 14, a first circumferential joint 15, a second circumferential joint 16, a third circumferential joint 17, a fourth circumferential joint 18 and a core column 19; The plate 11 is fixed horizontally on the upper end surface of the nuclear column 19, and the upper end plate 11 and the nuclear column 19 are connected by welding; the lower end plate 12 is horizontally fixed on the lower end surface of the nuclear column 19, and the lower end plate and the nuclear column 19 are welded Connection; the upper end joint 13 is vertical...

Embodiment 2

[0047] Reference attached Figure 8-10 As shown, embodiment 2 of the present invention provides a kind of edge node of assembled steel frame structure, comprises edge node core 5, box-type column 2, truss frame beam 3 and self-tapping bolt 4; Edge node core 5 and box-type column respectively 2 is connected with the truss frame beam 3;

[0048] The side node nucleus 5 comprises an upper end plate 11, a lower end plate 12, an upper end joint 13, a lower end joint 14, a first peripheral joint 15, a second peripheral joint 16, a third peripheral joint 17 and a nuclear post 19; the upper end plate 11 is fixed horizontally on The upper end surface of the nuclear column 19 is connected by welding between the upper end plate 11 and the nuclear column 19; the lower end plate 12 is horizontally fixed on the lower end surface of the nuclear column 19, and the lower end plate and the nuclear column 19 are connected by welding; the upper end joint 13 is vertical It is arranged on the uppe...

Embodiment 3

[0053] Reference attached Figure 11-13 As shown, an assembled steel frame structure corner joint of the present invention comprises corner joint core 6, box-shaped column 2, truss frame beam 3 and self-tapping bolt 4; 3 connections;

[0054] Corner node nucleus 6 includes upper end plate 11, lower end plate 12, upper end joint 13, lower end joint 14, first peripheral joint 15, second circumferential joint 16 and core column 19; The upper end plate 11 and the nuclear column 19 are connected by welding; the lower end plate 12 is horizontally fixed on the lower end surface of the nuclear column 19, and the lower end plate and the nuclear column 19 are connected by welding; the upper end joint 13 is vertically arranged on the upper end plate 11 On the upper surface, the upper end joint 13 and the upper end plate 11 are connected by welding, the lower end joint 14 is vertically arranged on the lower surface of the lower end plate 12, and the lower end joint 14 and the lower end p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com