Aero-engine rectifier cover based on Magnus effect

A technology of aero-engines and fairing caps, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of increasing the complexity of aero-engine control systems and the inability to generate aircraft lift, so as to save fuel consumption and save anti-icing Bleed air system, the effect of saving performance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

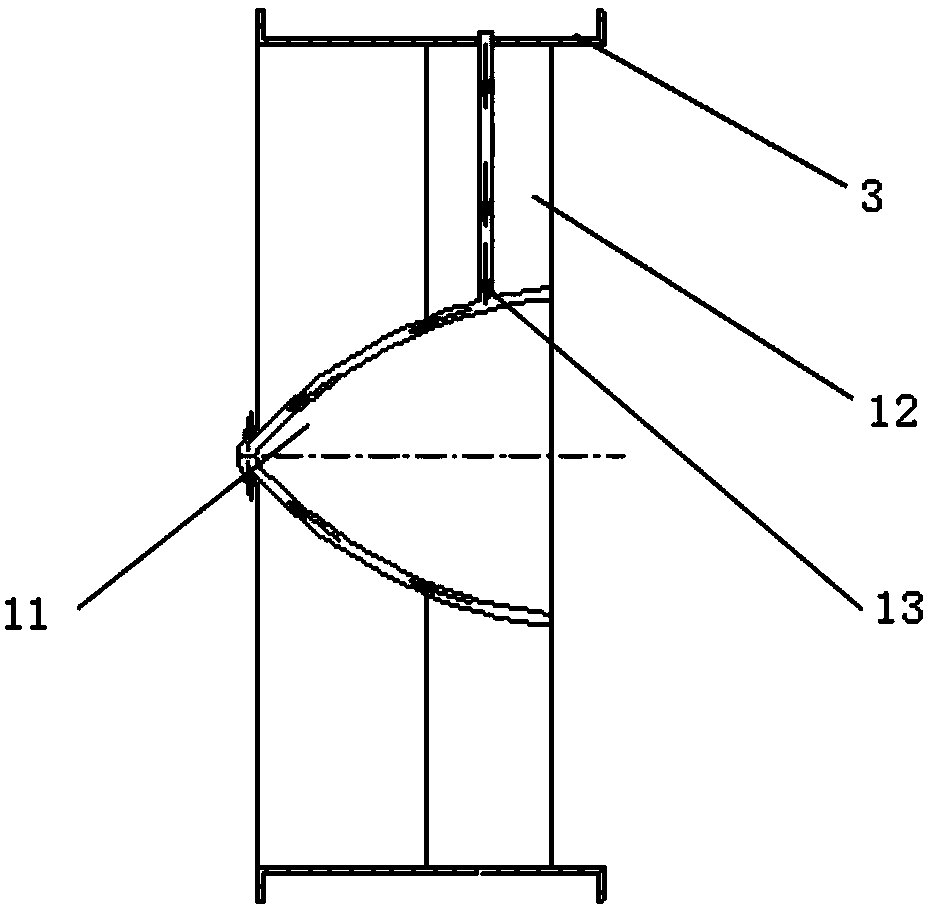

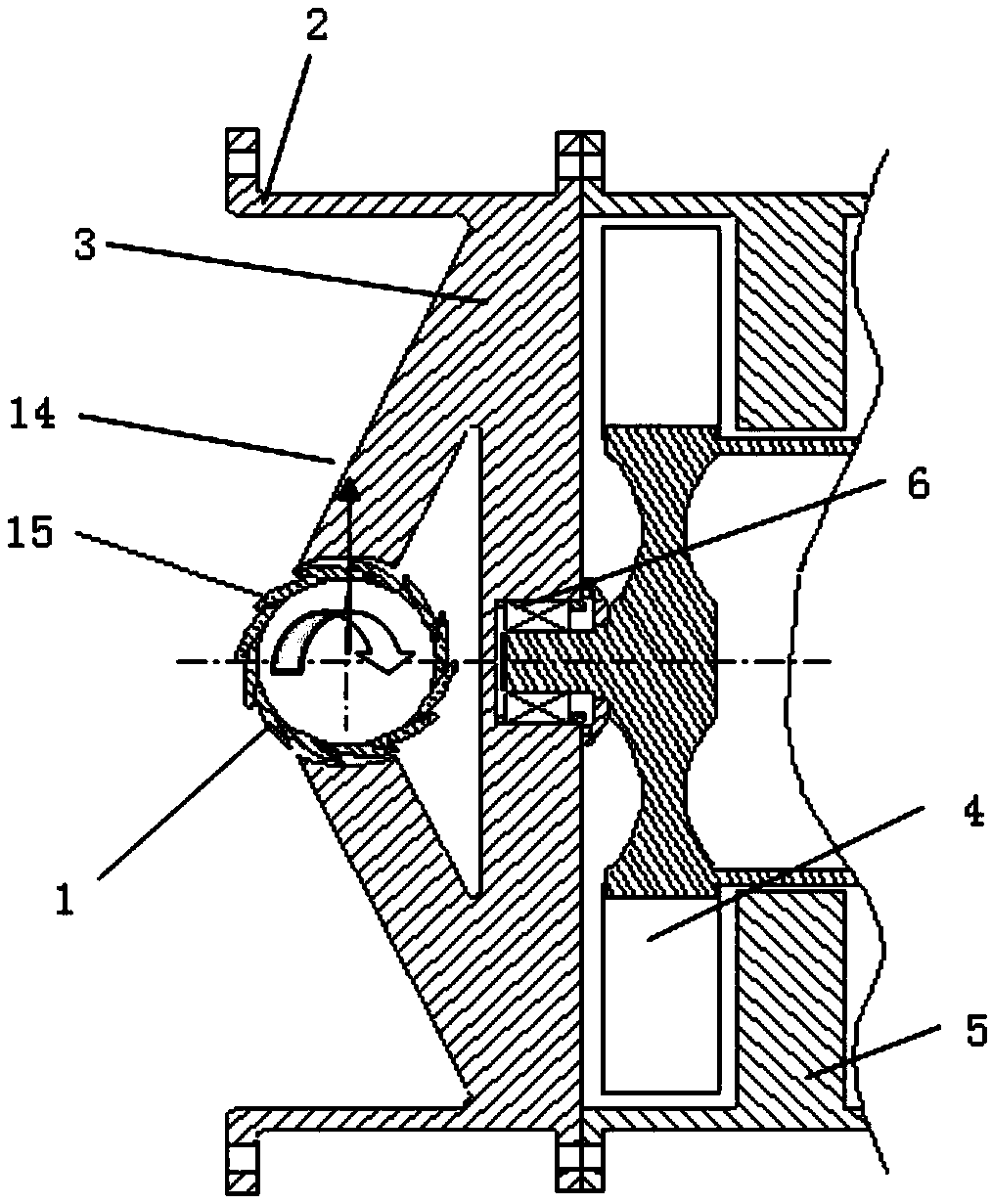

[0030] Such as Figure 1-7 Shown is an aero-engine cowling based on the Magnus effect, including a self-rotating cowling 1, a special-shaped rectifying strut 2, an intake casing 3, a low-pressure rotor 4, a low-pressure stator 5, and a front fulcrum bearing 6;

[0031] The self-rotating fairing cap 1 is spherical, and the sphere is provided with a crescent-shaped protrusion 15 that falls counterclockwise;

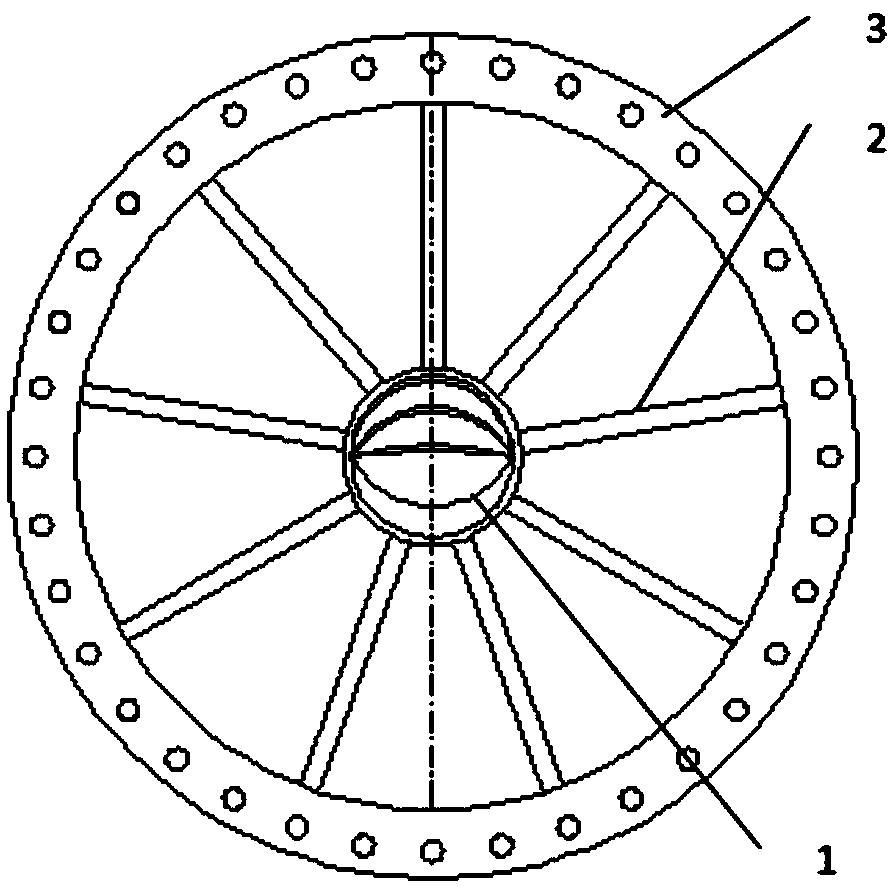

[0032] The outer ring of the front end of the air intake casing 3 is provided with a mounting edge, and the mounting edge is provided with a plurality of screw holes for connecting with the air intake at the front end of the aircraft;

[0033] The special-shaped rectifying support plate 2 is welded between the outer ring and the inner ring at the front end of the intake casing 3;

[0034] The horizontal ends of the self-rotating rectifying cap cover 1 are provided with holes with steps, and the holes are mounting seats for the outer ring of the self-lubricating bearing 10;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com