Vehicle man-machine verification platform

A verification platform and human-machine technology, applied in the field of vehicle human-machine verification platform, can solve the problems of difficult fine-tuning, incomplete functions, and inability to install solid parts, so as to reduce the design cost, shorten the manufacturing cycle, and improve the design quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

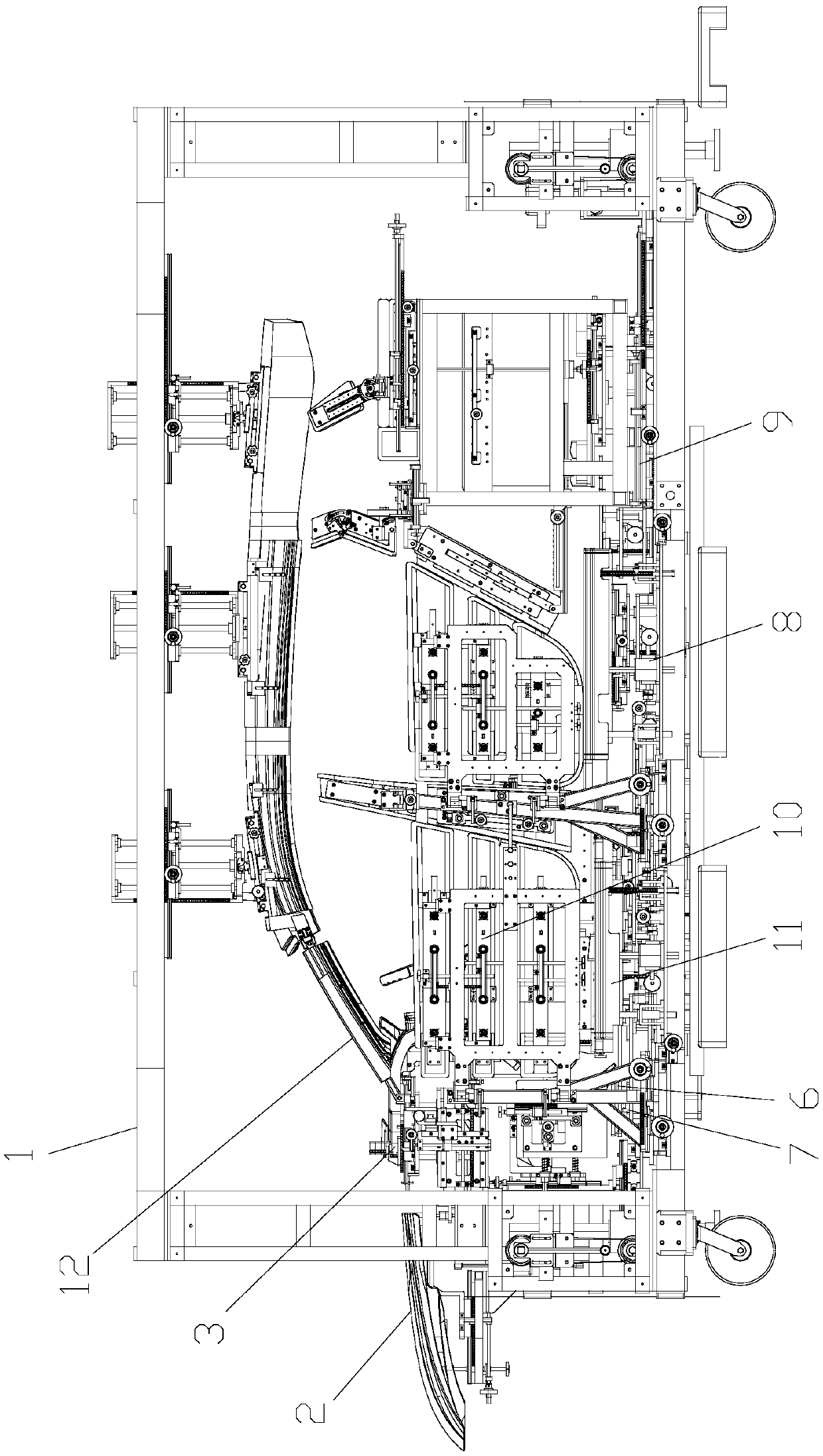

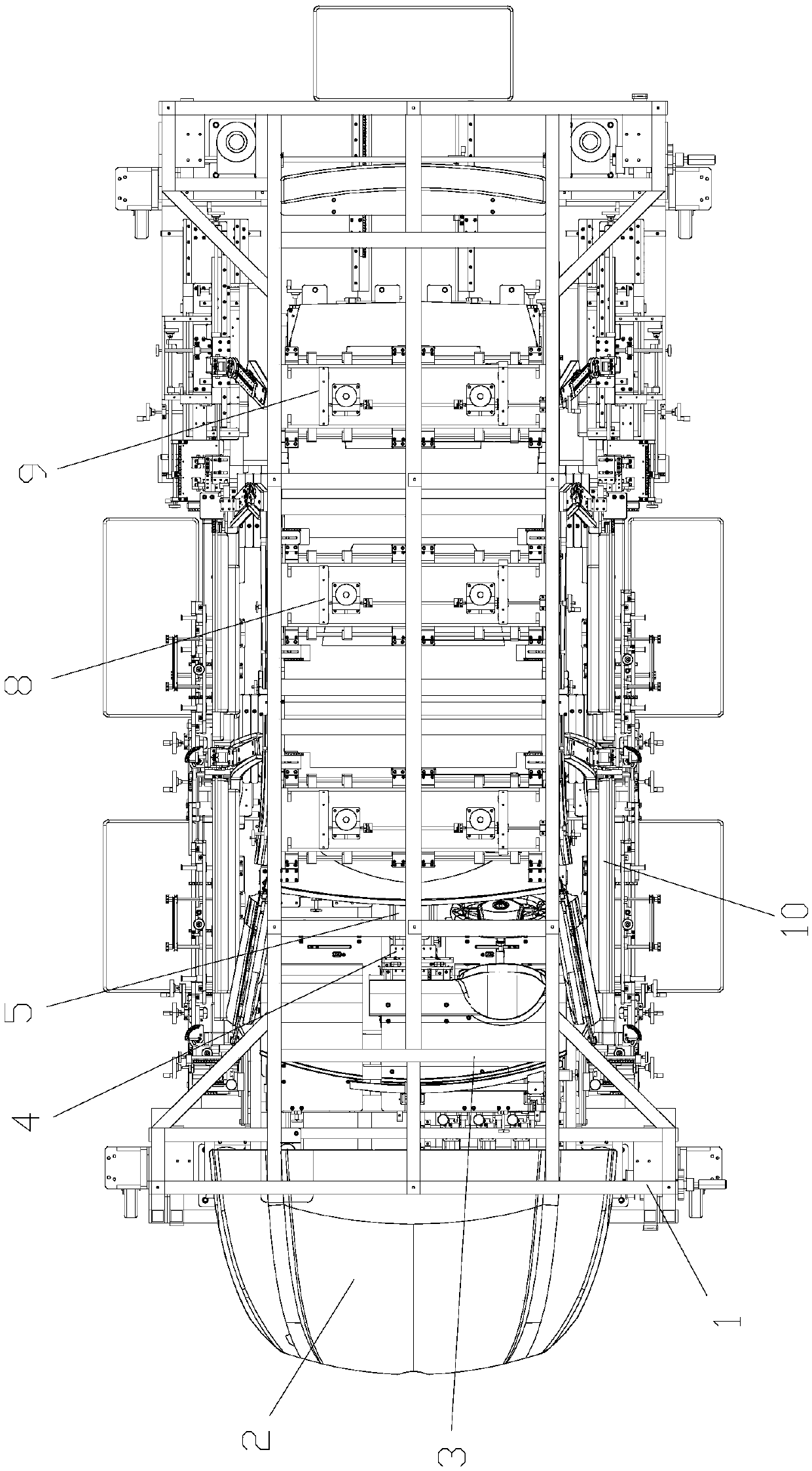

[0017] Such as Figure 1 to Figure 2 As shown: the vehicle man-machine verification platform of this embodiment includes a support frame assembly 1, a hood adjustment assembly 2, an instrument panel adjustment assembly 3, a shift adjustment assembly 4, a central armrest adjustment assembly 5, and a pedal adjustment assembly Assembly 6, brake adjustment assembly 7, seat adjustment assembly 8, third row floor adjustment assembly 9, door adjustment assembly 10, threshold adjustment assembly 11 and A-pillar adjustment assembly 12, the hood adjustment Assembly 2, instrument panel adjustment assembly 3, shift adjustment assembly 4, central armrest adjustment assembly 5, pedal adjustment assembly 6, and brake adjustment assembly 7 are located on the Y-direction side of the support frame assembly 1. The seat adjustment assembly 8 and the third-row floor adjustment assembly 9 are located in the middle of the support frame assembly 1, and the door adjustment assembly 10, threshold adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com