Porous metal support permeability testing device and surface cleaning device as well as porous metal support permeability testing method and surface cleaning method

A porous metal and testing device technology, applied in the direction of permeability/surface area analysis, measuring device, cleaning method and utensils, etc., can solve the problems of powder splashing, adhesion, surface spheroidization, etc., achieve high test accuracy, simple device, The results are accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

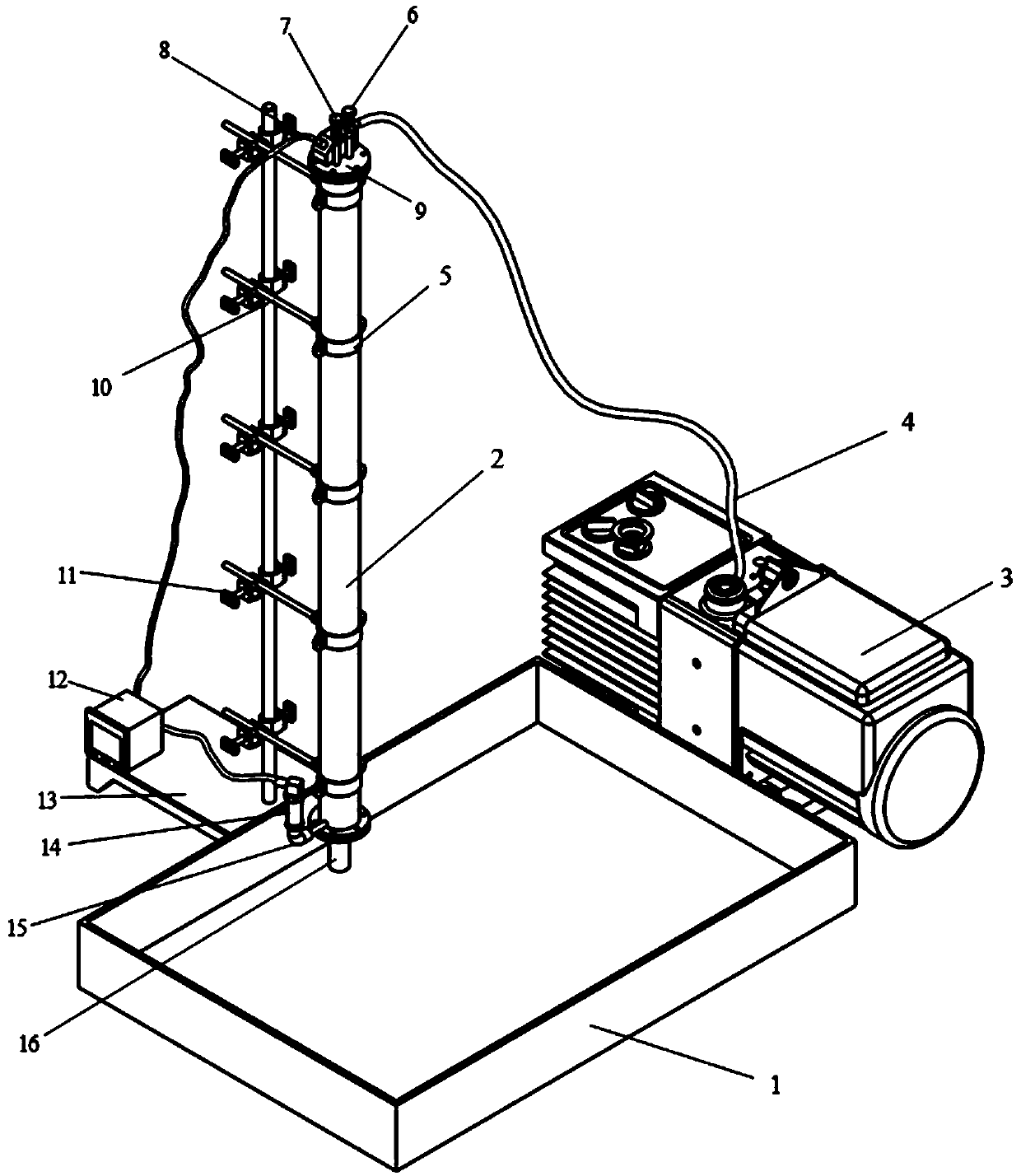

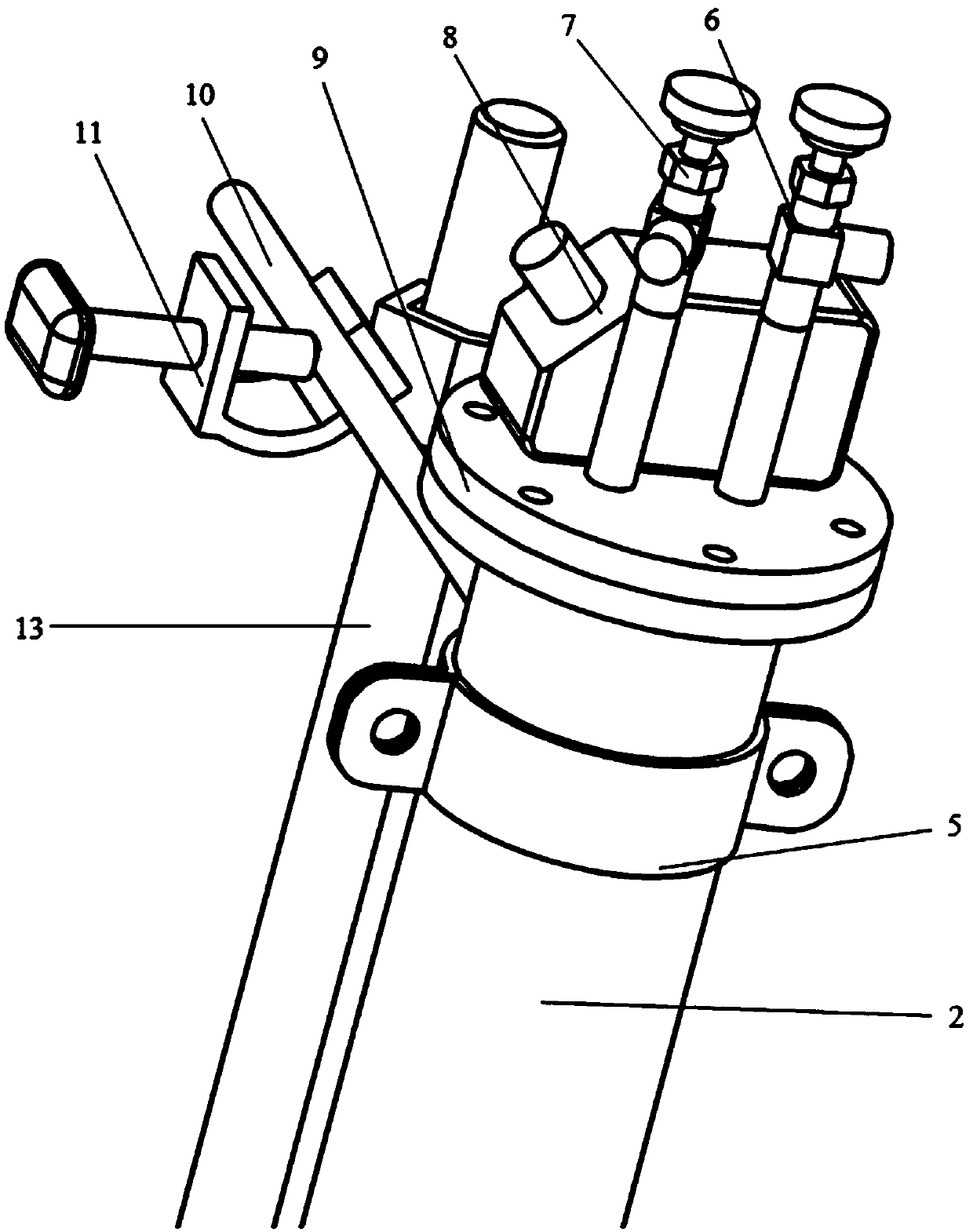

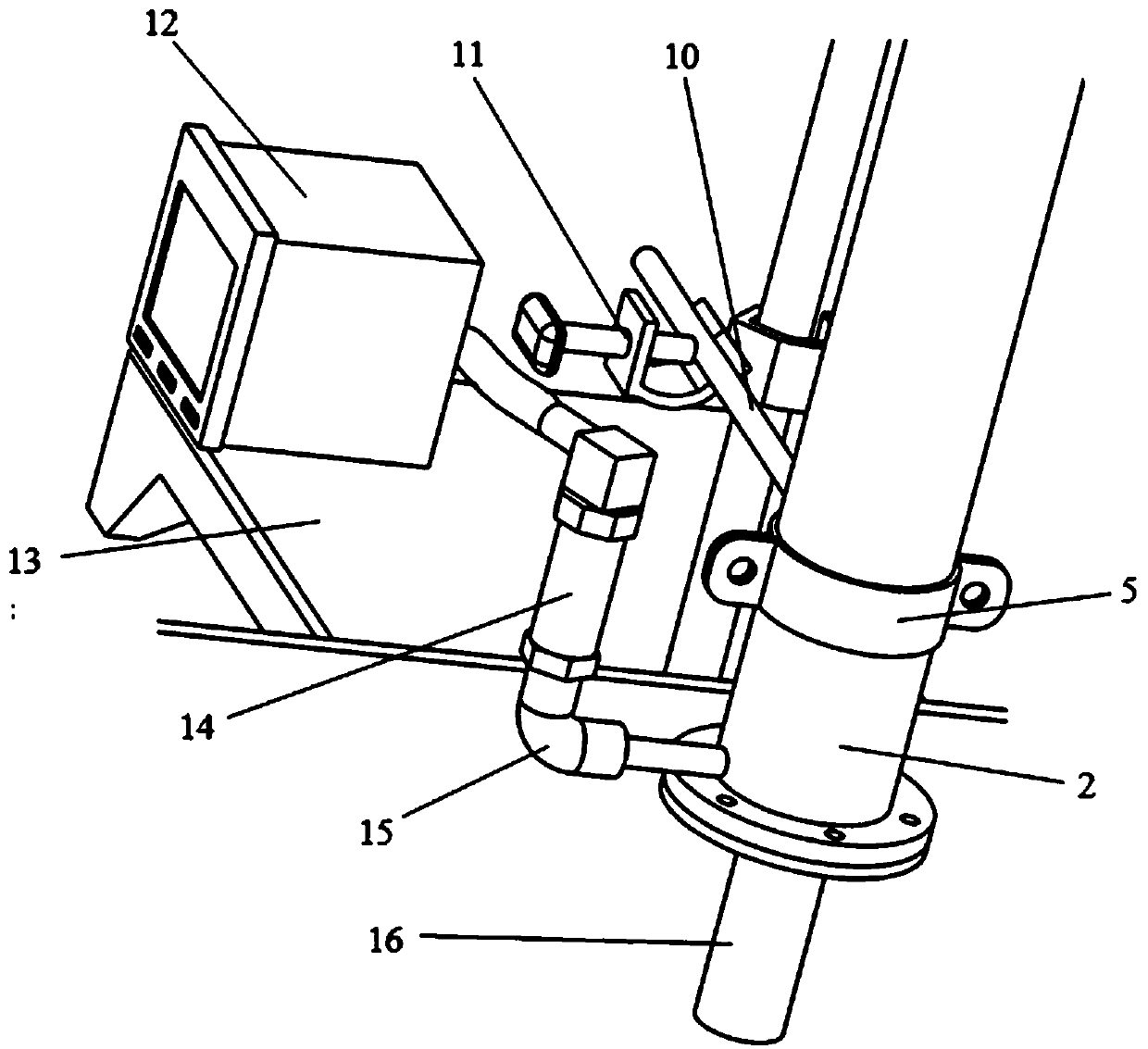

[0039] Such as figure 1 As shown, the embodiment of the present invention provides a porous metal support permeability testing device, which includes a water tank 1 , a sample fixing table 16 , a vacuum tube 2 , a vacuum pump 3 and a data receiving recorder 12 . The vacuum tube 2 is installed on the iron stand 13, and the vacuum tube 2 is fixed on the straight rod of the iron stand 13 using a cross clamp 11, a hoop tube clip 5 and a pipe clamp hoop 10. The data receiving recorder 12 is then placed on the straight plate of the iron frame platform 2 .

[0040] The sample fixing table 16 is connected to the vacuum tube 2 through flange bolts, and a sealing ring is provided at the junction of the vacuum tube 2 and the sample fixing table 16 to ensure the airtightness of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com