Overlying strata dynamic position prediction method considering mining rock mass crushing and swelling performance

A technology of overlying rock detachment and dynamic position, applied in special data processing applications, instruments, electrical digital data processing, etc., which can solve the deviation of prediction results, without considering differences, and detachment can only occur in adjacent "rock formations" problems such as the contact surface, to achieve accurate prediction results, reasonable mechanical models, and the effect of correcting defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0044] The burial depth of the coal seam in the 745 working face of an eastern mine is 327.76-382.08m, the mining height of the coal seam is M=2.3m, the strike length is 400m, and the inclination width is 60-120m. See Table 1 for specific stratum occurrence and physical and mechanical parameters. The single longwall caving coal mining method is adopted in this working face, and water inrush occurs when the mining strike length is about L=150m.

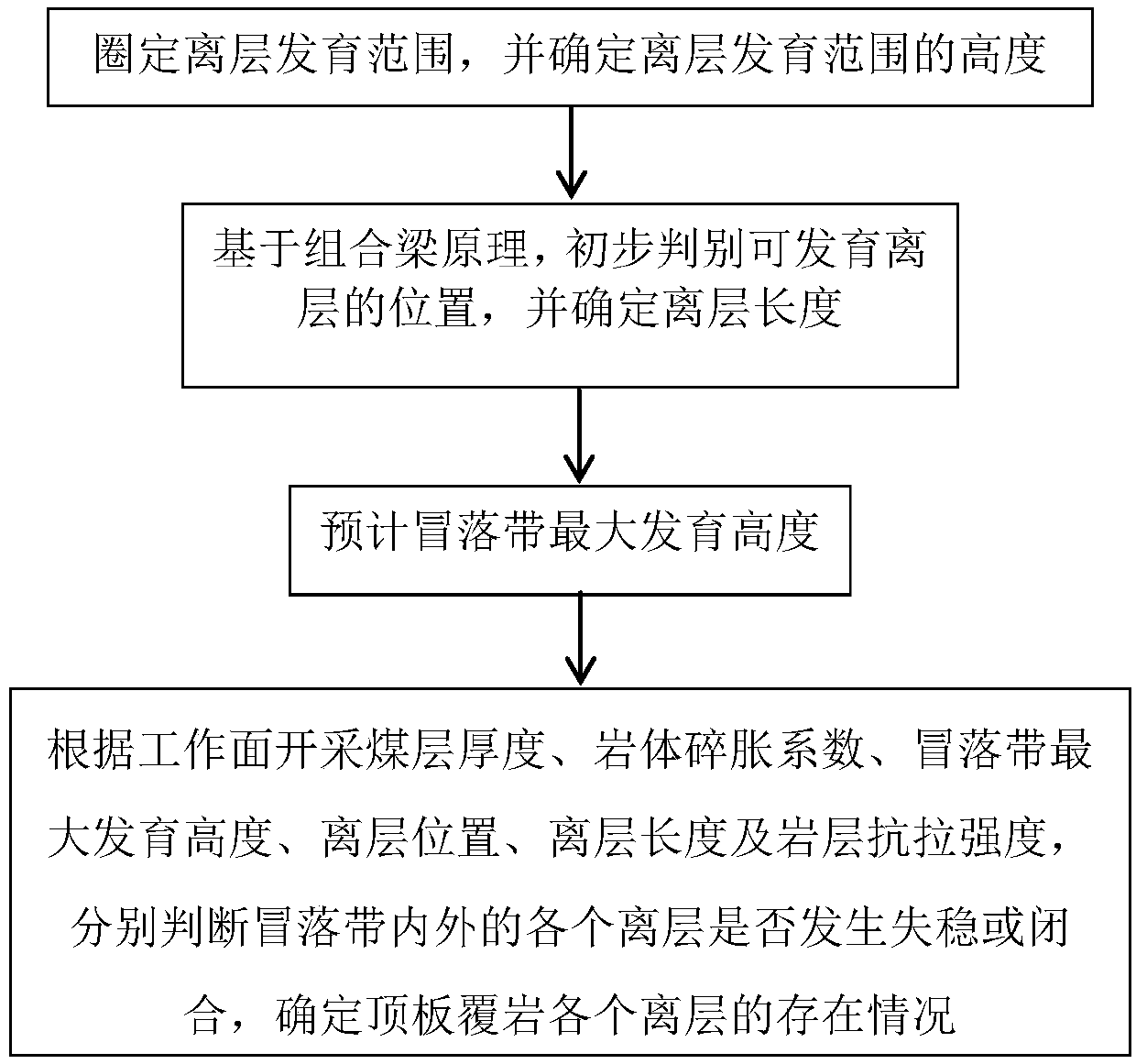

[0045] Utilize the method provided by the present invention to predict the detachment development of the 745 working face when the footage is 150m, such as figure 1 As shown, the specific steps are as follows:

[0046] The first step is to determine the development range of the separation layer according to the footage of the working face and the fracture angle of the rock formation:

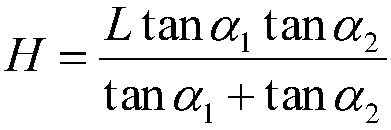

[0047] The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com