Fuel cell board molding manufacturing device

A technology for fuel cells and manufacturing equipment, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of increased pressure demand, low production efficiency, and inability to meet at the same time, so as to improve consistency, production capacity, and increase production efficiency. , The effect of easy control of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

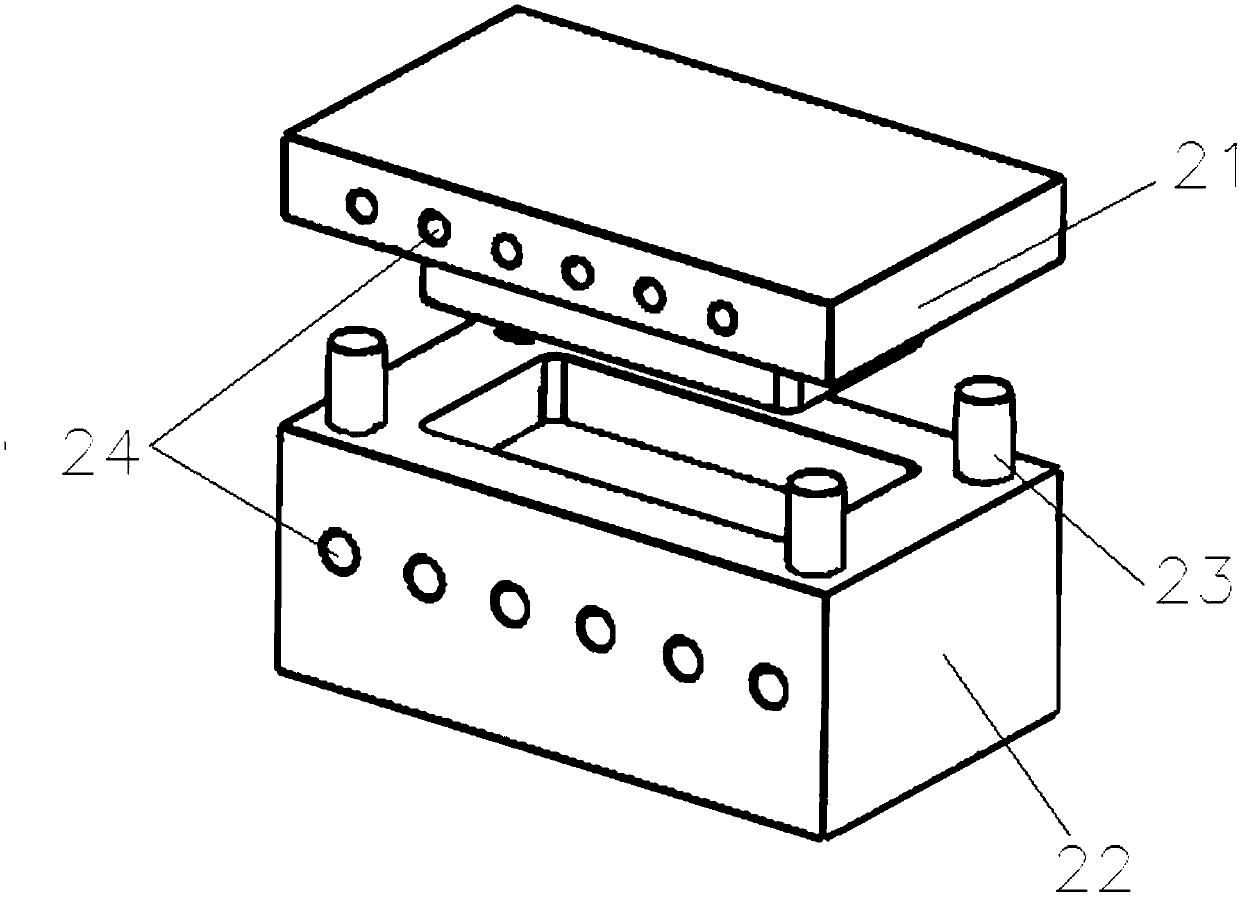

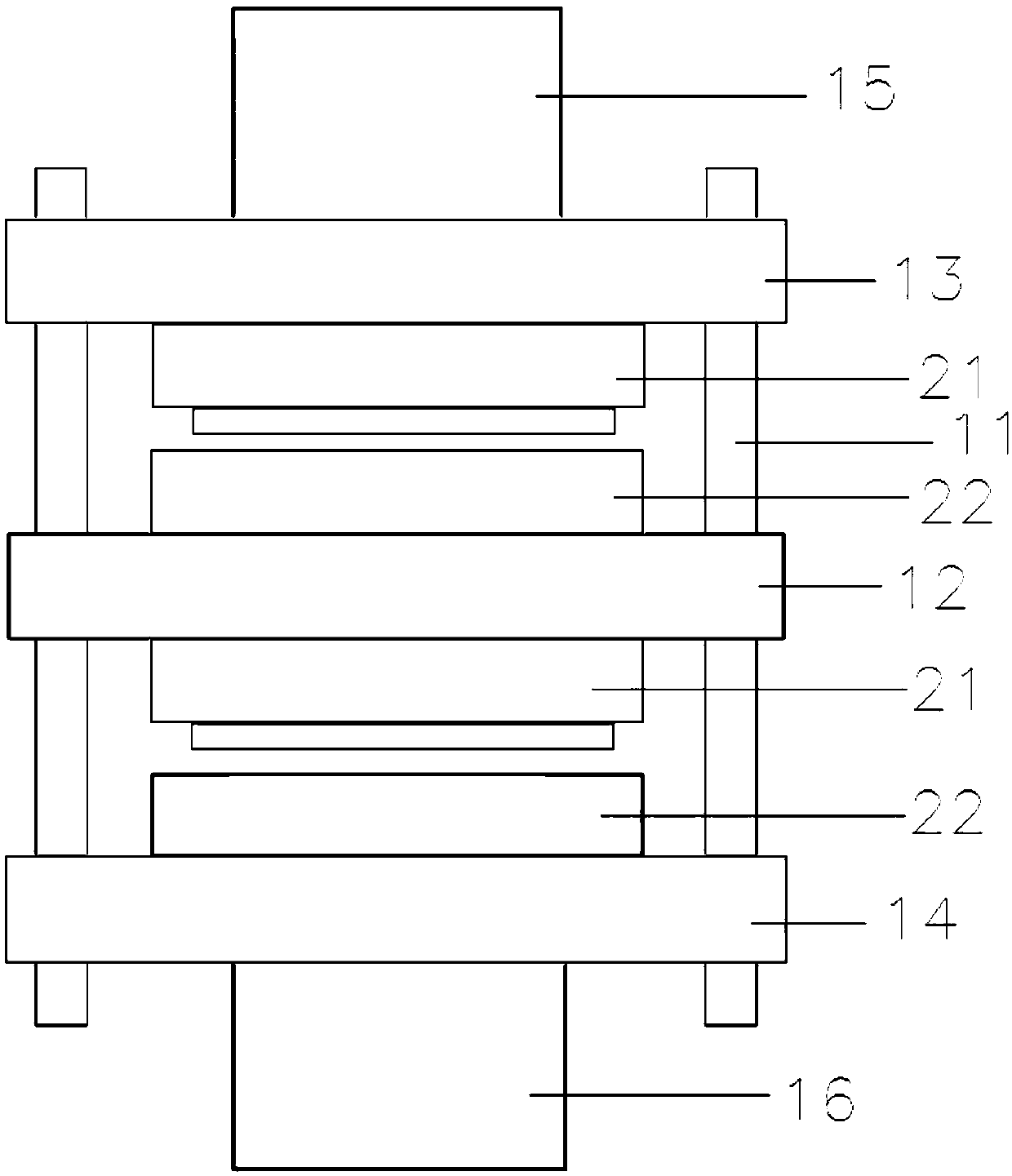

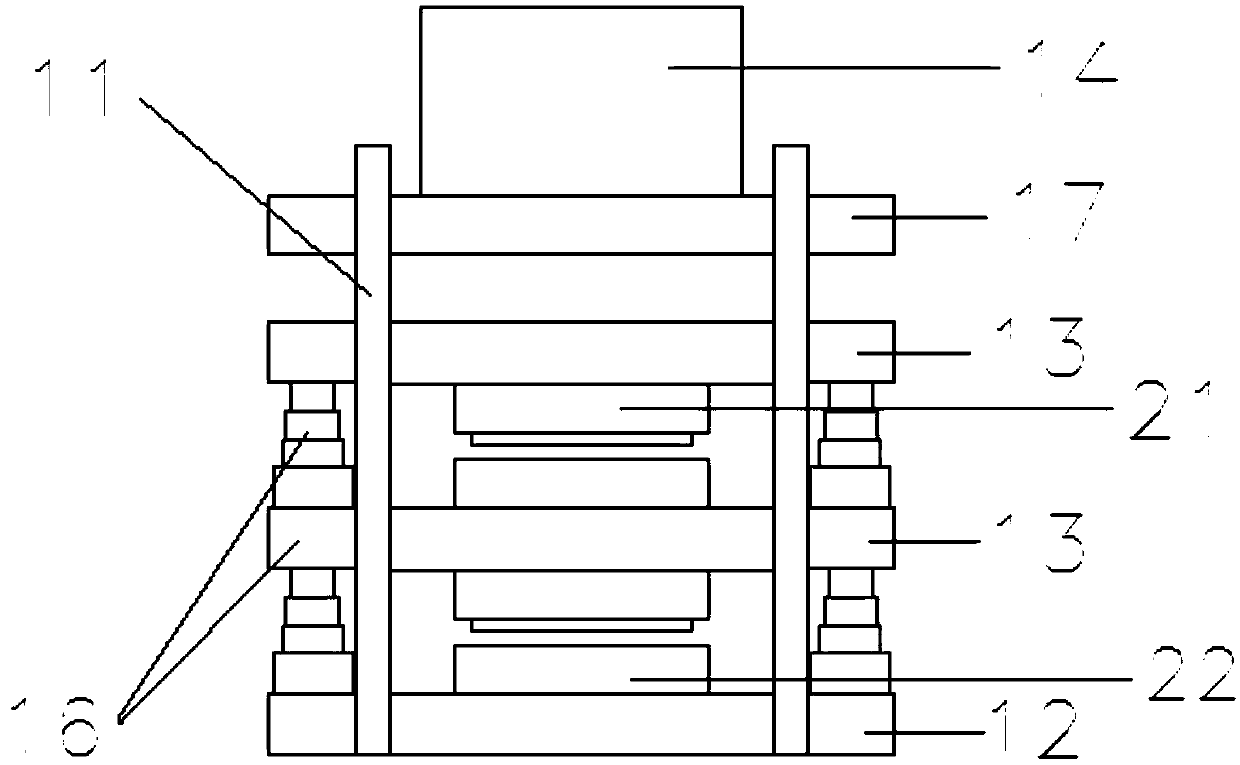

[0024] refer to figure 2 , the first embodiment of the fuel cell plate molding manufacturing equipment of the present invention includes a fixed frame 11 , a fixed block 12 , two movable sliders 13 , an upper hydraulic cylinder 14 and a lower hydraulic cylinder 15 . The fixed frame 11 comprises two parallel supports, the fixed block 12 is erected and fixed on the fixed frame 11, the fixed frame 11 is provided with a guide rail, the movable slider 13 is slidably connected with the fixed frame 11, and can slide up and down along the guide rail. The two movable sliders 13 are respectively arranged above and below the fixed block 12, the lower end surface of the upper hydraulic cylinder 14 is against the upper end surface of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com