Bearing shell for half shell bearing, half shell bearing and use thereof

A technology of bearing shells and bearings, which is applied in the direction of rotating bearings, bearings, roller bearings, etc., can solve the problems of reduced rib elasticity, reduced elasticity, and increased cost, and achieve reduced material thickness, cost savings, and reduced costs. Small, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

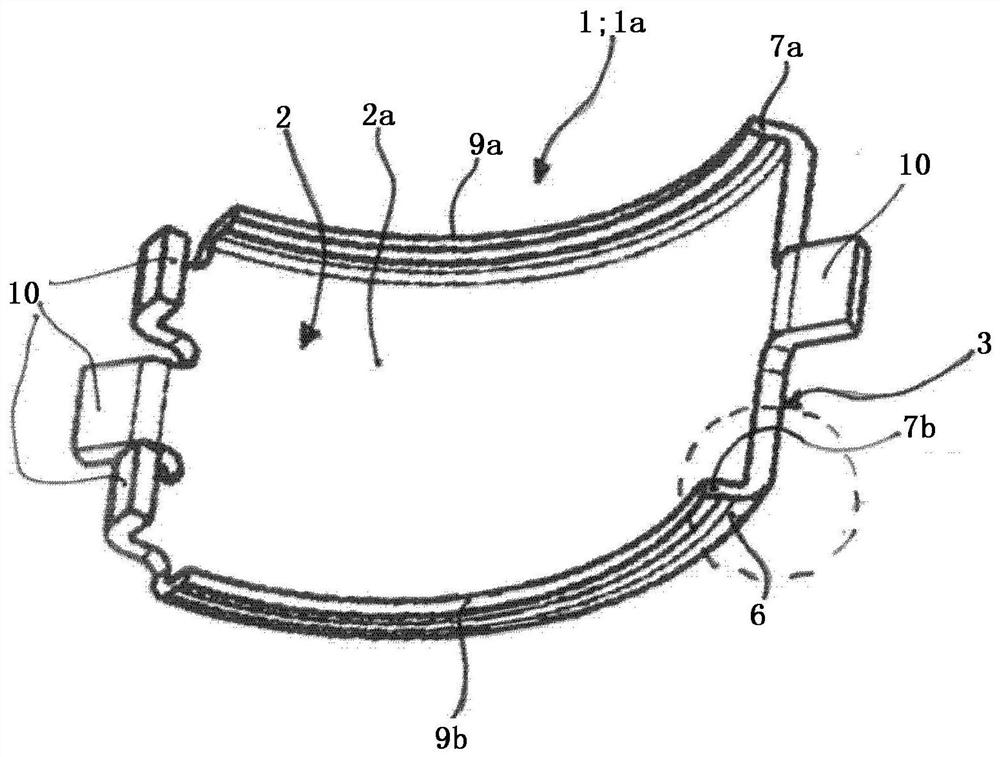

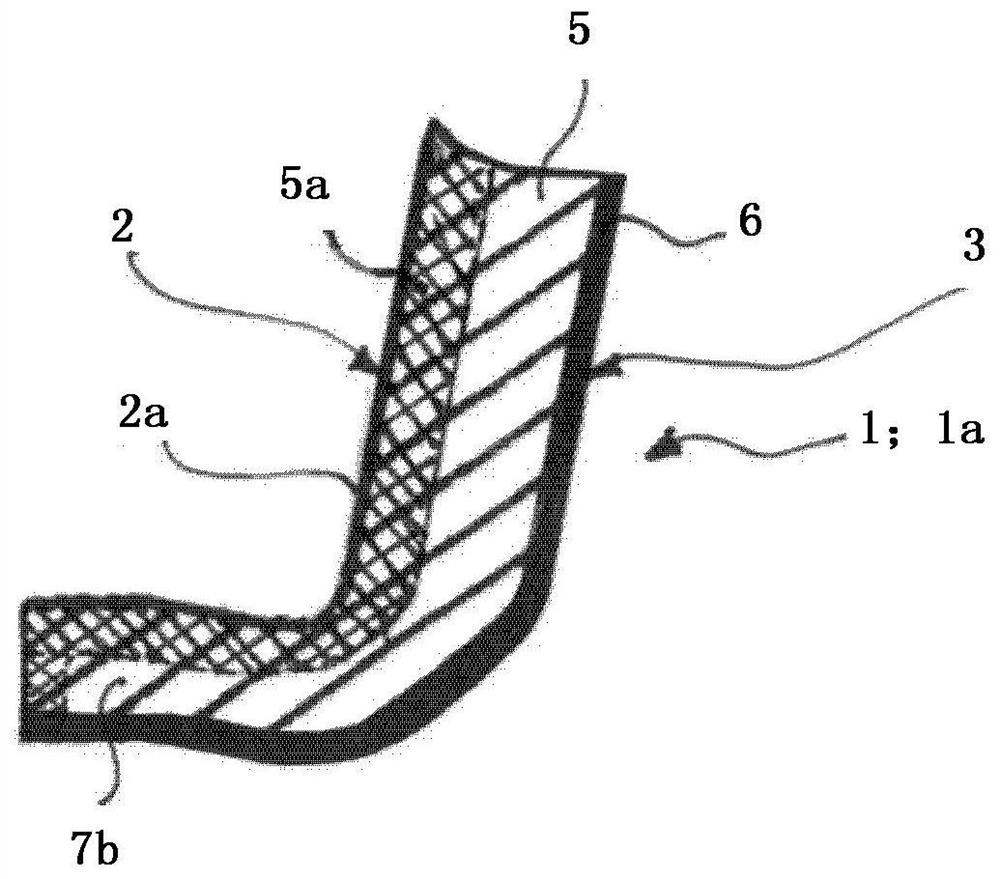

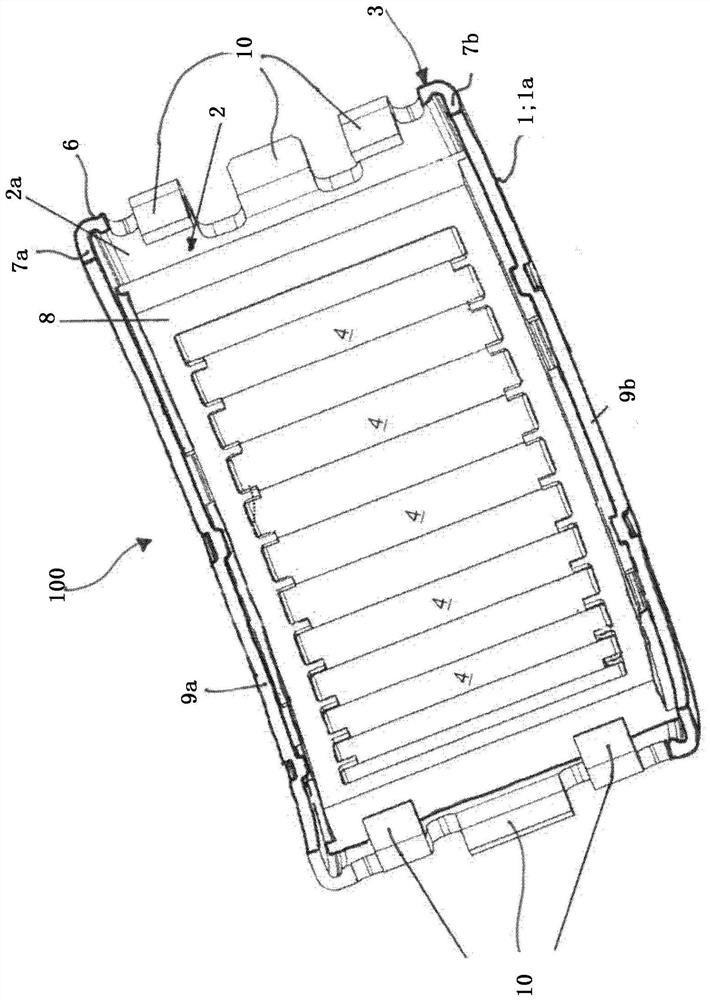

[0030] figure 1 In three-dimensional view illustrating a bearing housing having two longitudinal sides 9a, 9b of 1; 1a, wherein, in each longitudinal side 9a, 9b are arranged toward the direction of the raceway for the rolling bodies 2a directed stop side 7a, 7b. figure 2 It illustrates in cross-section according to figure 1 The bearing housing 1; amplified fragment area in the flange 1a, 7b. Bearing housing 1; 1a to harden the hardening method. Bearing housing 1; 1a has a body 5 made of steel (see figure 2 ), And having a raceway for rolling elements 2 on the first side 2a. A second body 5 facing away from the side of the first side 2 has a coating 3 made of a coating material 6, it is set up as a coating material, during the execution of hardening method for forming the carbon in the region of the second side 3 5 toward the direction of the main body of the diffusion barrier. According to figure 2 7b is a section through the wall, in enlarged view, on the side of the first laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com