Weighing and feeding ball feeder for ball mill

A technology of ball mill and ball adding machine, which is applied in the field of machinery to achieve stable efficiency, improve product quality, and reduce unit energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

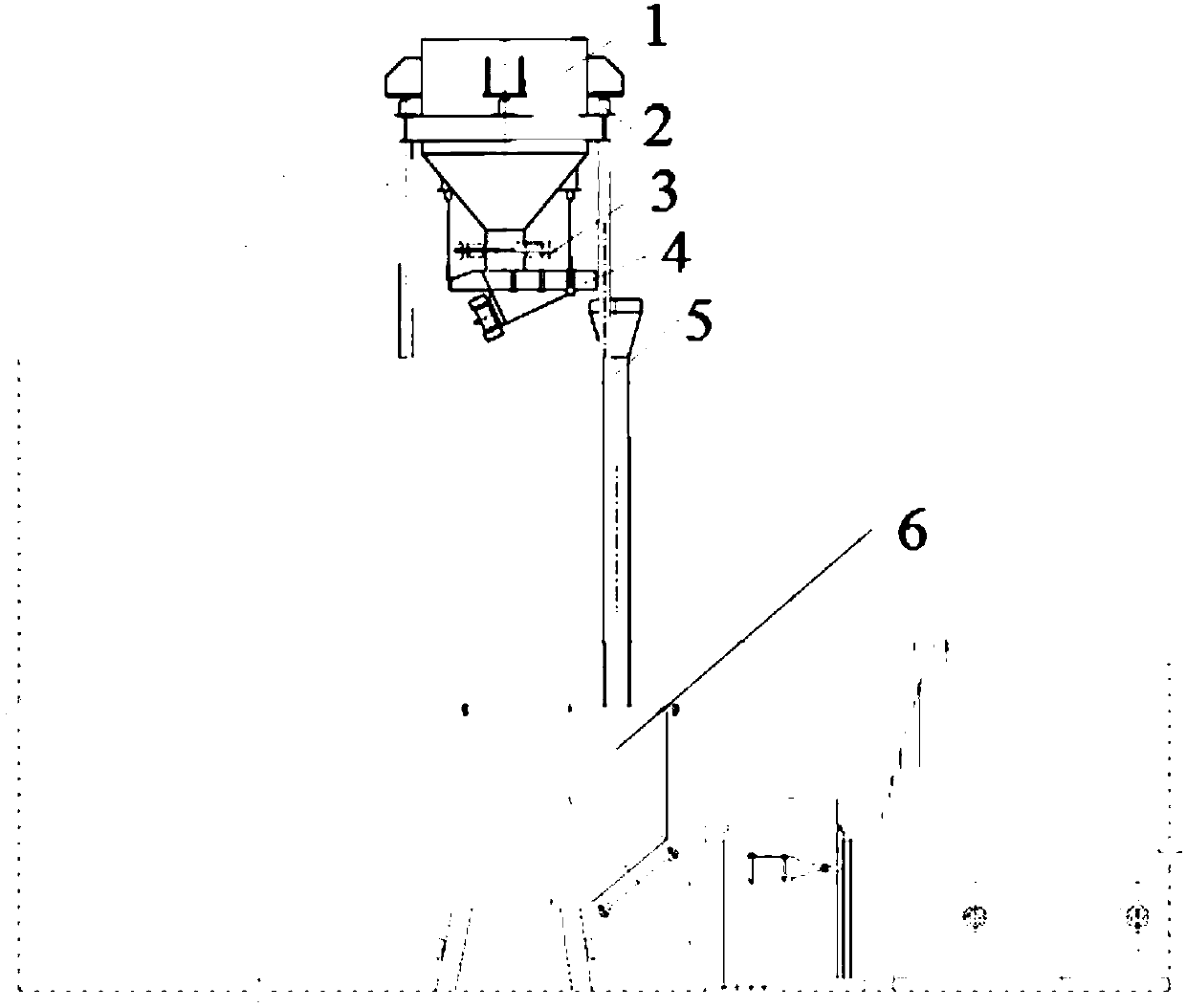

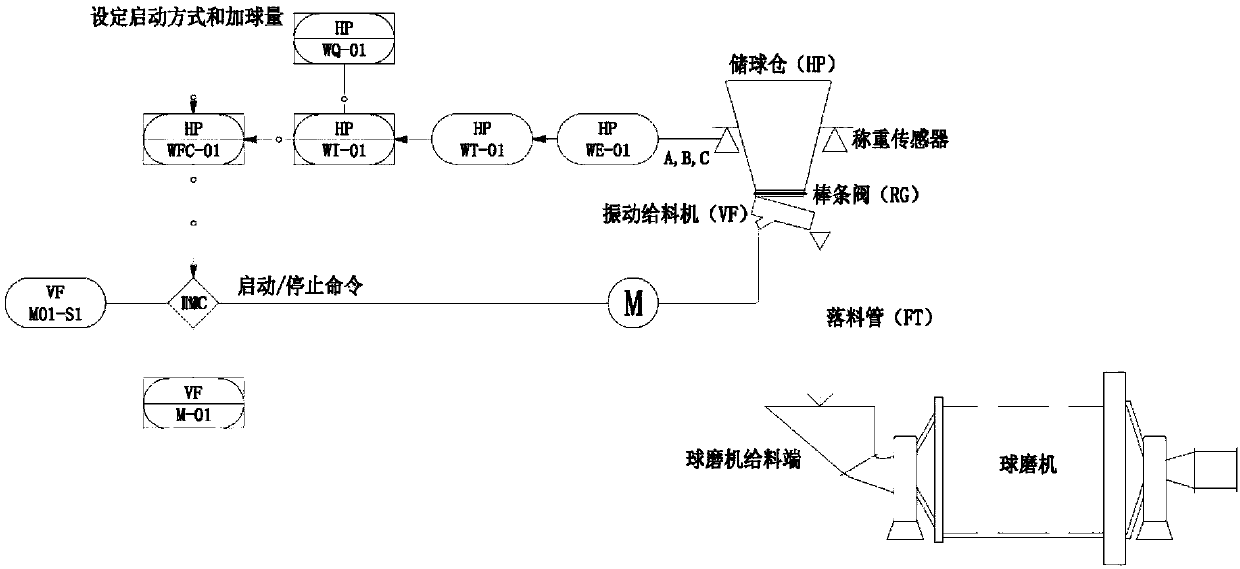

[0016] The embodiment of the present invention proposes a figure 1 The weighing feeding ball feeding machine for ball mill shown includes: storage bin 1 with load cell 2, rod valve 3, motor vibrating feeder 4, and drop pipe 5; among them, storage bin 1 It is located above the feeding end of the ball mill 6, and the bottom of the storage bin 1 is provided with a discharge port, and a rod valve 3 that can be opened and closed in a controlled manner is provided at the discharge port; wherein the storage bin 1 is equipped with Load cell 2; wherein the position of the discharge port at the bottom of the storage bin 1 is adapted to the position of the motor vibrating feeder 4, so that when the rod valve 3 of the discharge port is opened, the material is transp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap