Full-automatic corrugated pipe cleaning device

A cleaning device and bellows technology, which is applied in the direction of removing smoke and dust, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems that the inner wall of the bellows cannot be cleaned thoroughly, so as to improve the cleaning degree, ensure consistency, and ensure cleaning efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

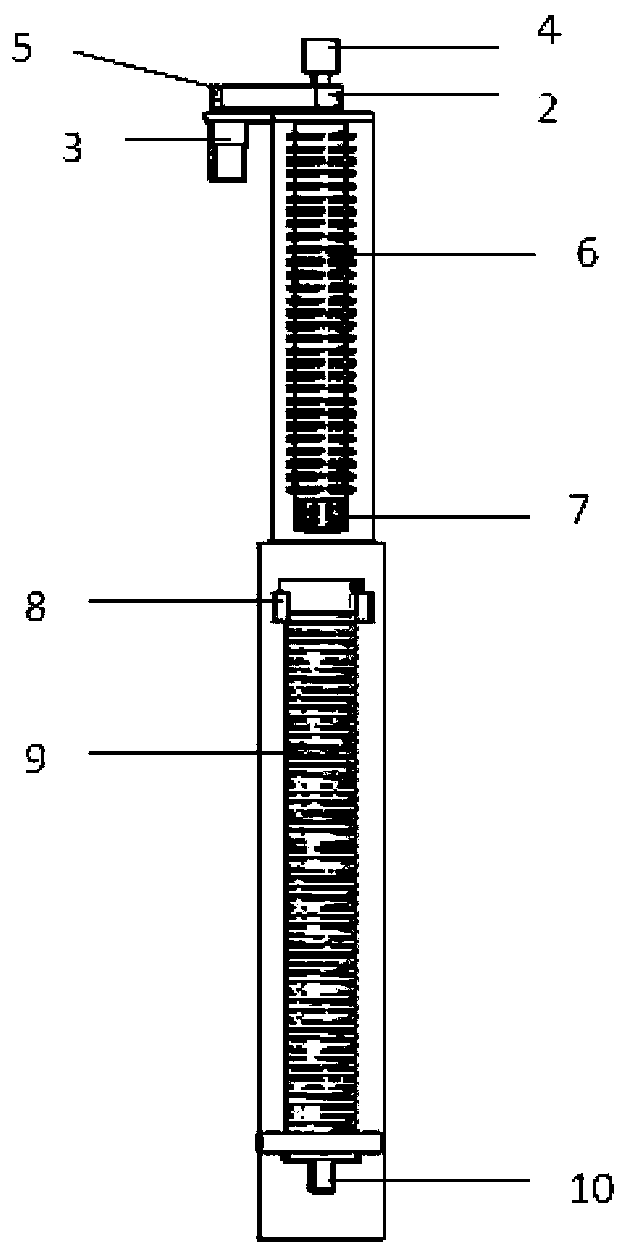

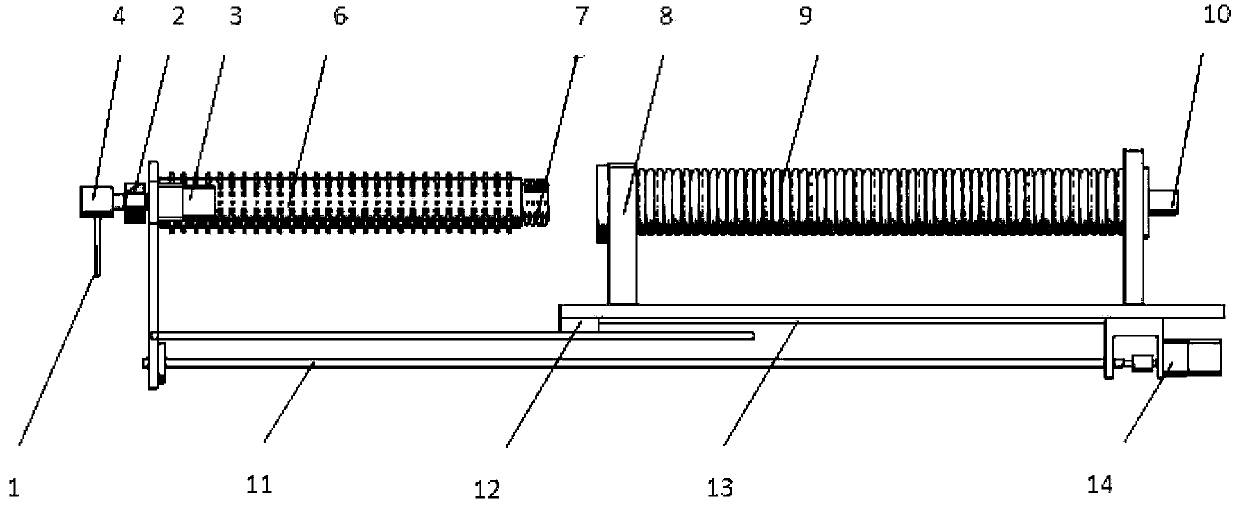

[0021] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] The fully automatic bellows cleaning device includes a vertically arranged cylindrical brush 6 and a sliding assembly; the handle of the brush 6 is movably mounted on the brush mounting bracket through a bearing, and the brush mounting bracket is fixed above the sliding assembly, sliding The bellows fixture 8 is fixedly set under the component, and the bellows 9 to be cleaned is installed in the bellows fixture 6; the brush 6 is located above the bellows 9, and the two are vertically coaxially arranged; the brush mounting bracket is provided with The rotating motor 3 and the belt 5 are installed between the pulley 2 of the handle of the brush 6 and the output shaft of the rotating motor 3, and the belt 5 drives the brush 6 to rotate; The leading screw 11 drives the brush 6 to move along the axial direction.

[0023] As an exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com