Shell and movement decomposition device of airplane pyrometer

An aircraft and watch core technology, applied in the field of aviation repair, can solve the problems of inconvenient separation of the watch core, virtual connection of circuit board pins, plugs, and circuit board connecting wires falling off, so as to shorten the decomposition time, improve the practicability, improve the The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

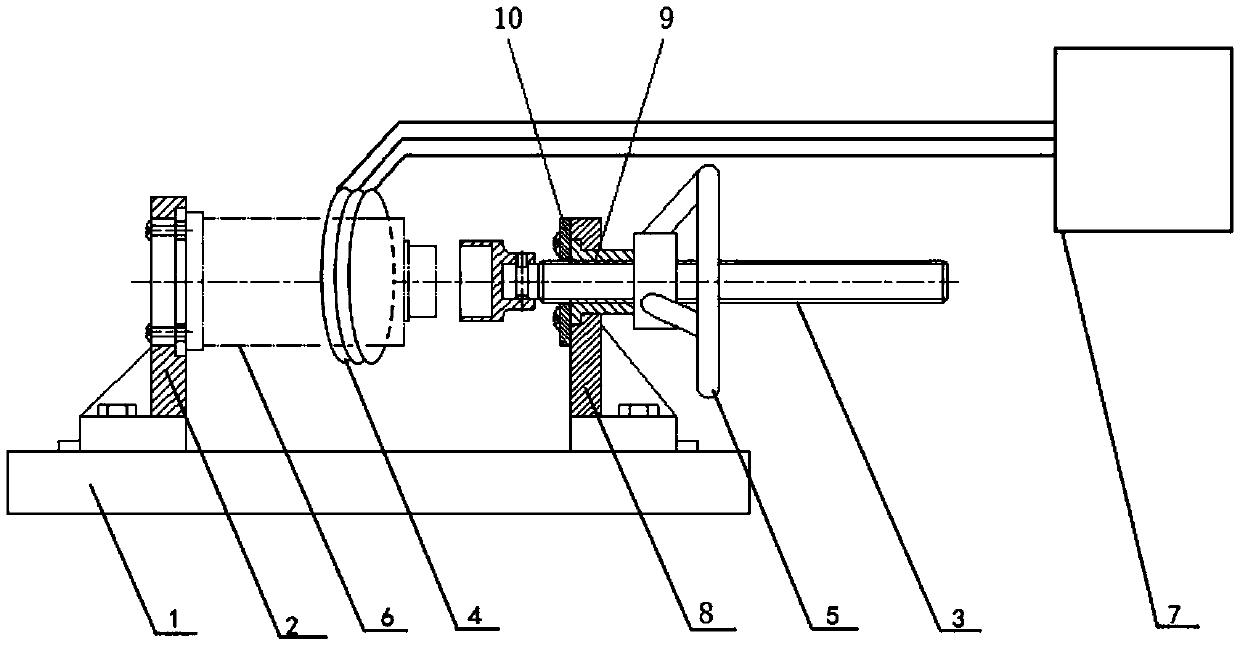

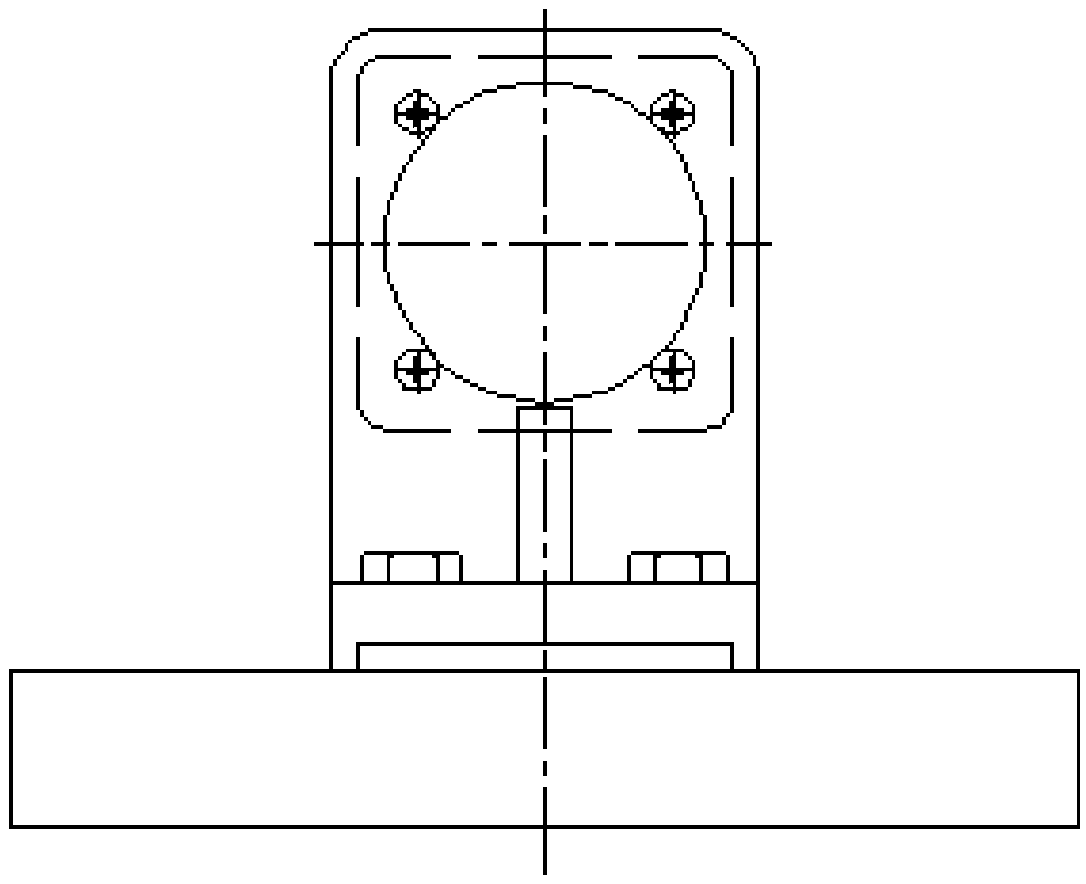

[0024] This embodiment provides a casing and watch core decomposition device for an aircraft exhaust temperature meter, see the attached figure 1 and 2 , including: a base 1, a first bracket 2, a second bracket 8, a snap ring 9, a cover plate 10, a screw 3, a handwheel 5 and an annular copper tube type welding ring 4;

[0025] The auxiliary equipment is high-frequency induction heating equipment 7; the object to be decomposed is the aircraft exhaust temperature table 6;

[0026] The four corners of the base 1 are processed with installation holes, and are fixed on the workbench through the installation holes, and the base 1 is used to support and fix the entire tooling;

[0027] The first bracket 2 is fixed on the base 1, and the first bracket 2 is processed with an installation through hole having the same shape and size as the aircraft exhaust temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com