Electronic mechanical hydraulic brake, braking control method and electronic hydraulic brake-by-wire system

A hydraulic brake, electronic machinery technology, applied in the direction of brake, brake transmission, transportation and packaging, etc., can solve problems such as the inability to guarantee the braking capacity of the vehicle, the inability of the wheels to maintain the braking force, affecting the safety of the vehicle, etc., and achieve a compact structure. , easy to operate, ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

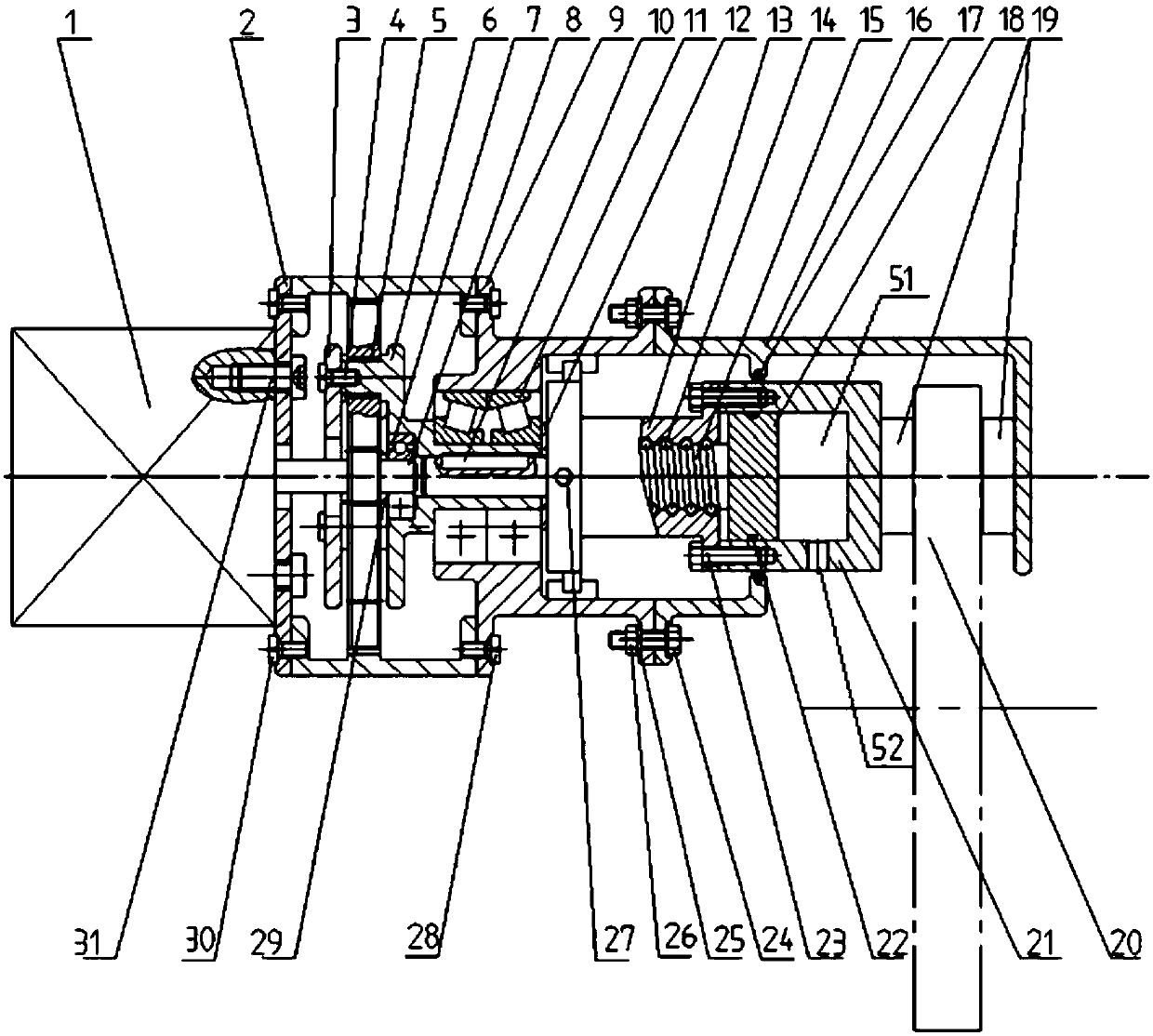

[0072] In order to further illustrate the technical scheme of the present invention and its specific working process, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

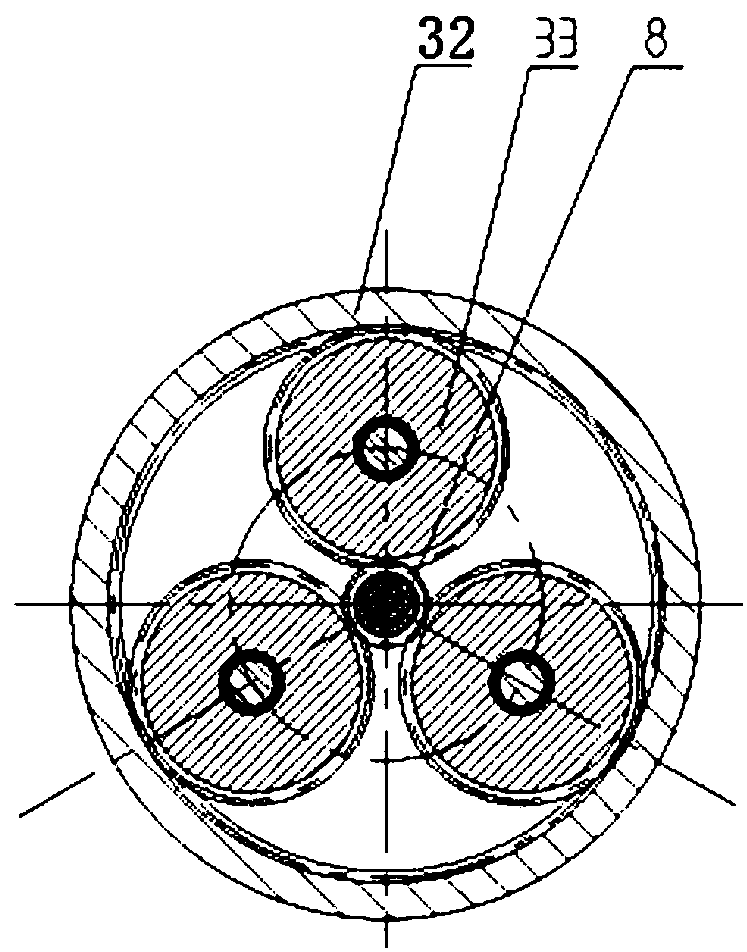

[0073] Such as figure 1 As shown, the present invention discloses an electromechanical hydraulic brake, which is composed of a motor, a planetary gear train assembly, a ball screw assembly, a brake wheel cylinder assembly, a box assembly, a friction lining and a brake disc; the motor , The planetary gear train assembly, the ball screw assembly, and the brake wheel cylinder assembly are arranged in sequence from back to front. The output shaft of the motor 1 is coaxially connected with the sun gear shaft 8 of the planetary gear train assembly. The frame is coaxially connected with the ball screw screw 15 of the ball screw assembly. The wheel brake cylinder cylinder 21 of the brake wheel cylinder assembly is fixedly connected with the ball screw nut 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com