Novel drive-by-wire electric braking system

A technology of electric braking and wire control, which is applied in the direction of braking safety systems, brakes, and braking transmission devices. Compact structure, achieve the effect of brake-by-wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

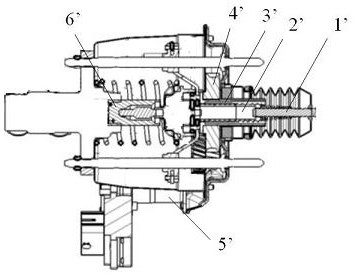

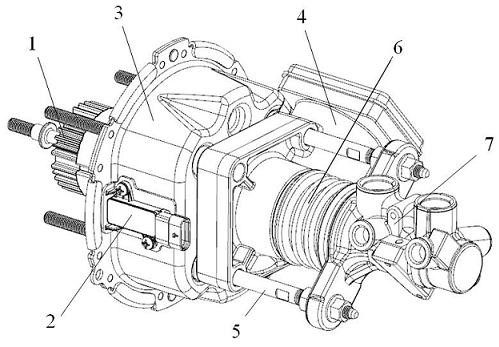

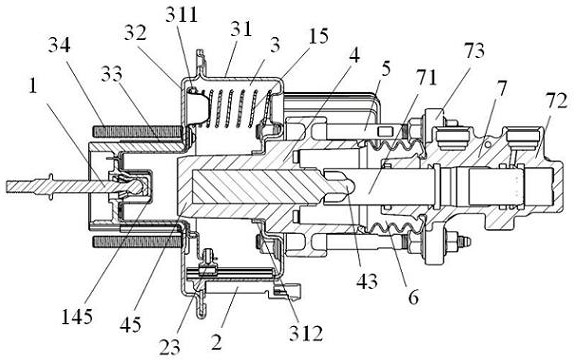

[0070] The present invention includes a pedal force transmission assembly 1, a pedal stroke sensor 2, a support housing 3, an electric push rod assembly 4, a guide rod 5, a protective cover 6, and a brake master cylinder 7; Figure 2-8 shown.

[0071] like image 3 , the support casing 3 includes a front casing 31 , a rear casing 32 , a center sleeve 33 , and a positioning bolt 34 , and the front casing 31 has a central hole 312 .

[0072] The pedal force transmission assembly 1 is installed in the center sleeve 33 of the support housing 3, and can slide axially therein; the pedal force transmission assembly 1 has a circumferentially arranged spring 15; the other end of the spring 15 supports On the inner spring seat 311 of the front housing 31 ; further, the spring 15 can be arranged at the center position of the pedal force transmission assembly 1 .

[0073] The pedal stroke sensor 2 is mounted on the support housing 3 and connected to the pedal force displacement assembly...

Embodiment 1

[0086] Based on Embodiment 1, the pedal force transmission assembly 1 includes a top rod 11 , a ball head cover 12 , a sliding sleeve 13 , a support sleeve 14 , a spring 15 , and an anti-vibration pad 16 , such as Figure 4 , Figure 5 shown.

[0087] The top rod 11 is a rod-shaped structure, the head 111 is a threaded structure or a fish-eye structure, and the tail 112 is a ball-head structure;

[0088] The sliding sleeve 13 includes an outer groove 131 , a positioning groove 132 , an undercut 133 and an inner assembly hole 134 .

[0089] Preferably, the outer groove 131 is a plurality of ribs and grooves arranged in the circumferential direction, which cooperate with the inner surface of the center sleeve 33 on the support shell 3; the cross-section of the ribs and grooves is not limited to a certain shape.

[0090] The ball head cover 12 is a hat-shaped structure, the mouth has an inverted buckle 121, the outer side is matched with the inner inverted buckle 133 of the sli...

Embodiment 3

[0101] Based on Embodiment 1, the pedal stroke sensor 2 is a linear displacement sensor, including a sensor body 21, a chute 22, a slider 23, and a positioning column 24, such as Image 6 .

[0102] The sensor body 21 can be a contact type or non-contact type, single-channel or multi-channel linear displacement sensor of any principle, such as a Hall type, an eddy current type, a sliding sheet resistance type, and the like.

[0103] The chute 22 is composed of a convex rib and a T-shaped groove, and cooperates with the convex rib on the slider 23 to prevent it from falling out when sliding, which affects the measurement accuracy.

[0104] The slider 23 may have built-in magnets or metal sheets, or built-in contacts according to the principle of the sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com