Material receiving device for surface treatment of automobile parts

A technology for auto parts and surface treatment, applied in transportation and packaging, conveyors, mechanical conveyors, etc., can solve problems such as collisions, low cost performance, loss of auto parts, etc., and achieve the effect of reducing manufacturing costs and solving transmission problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

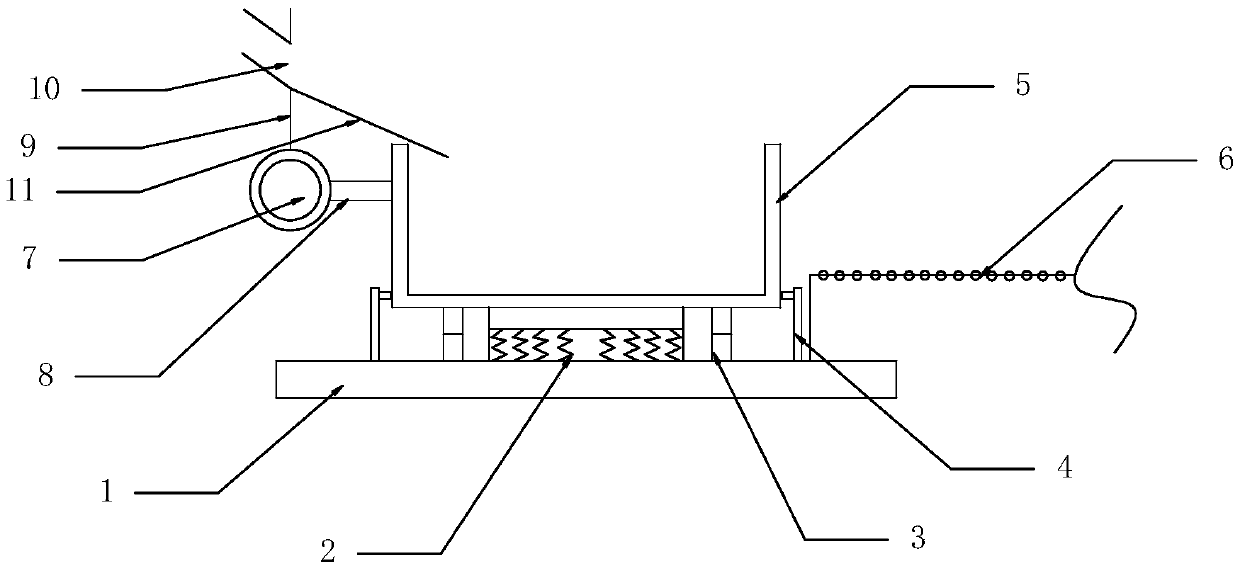

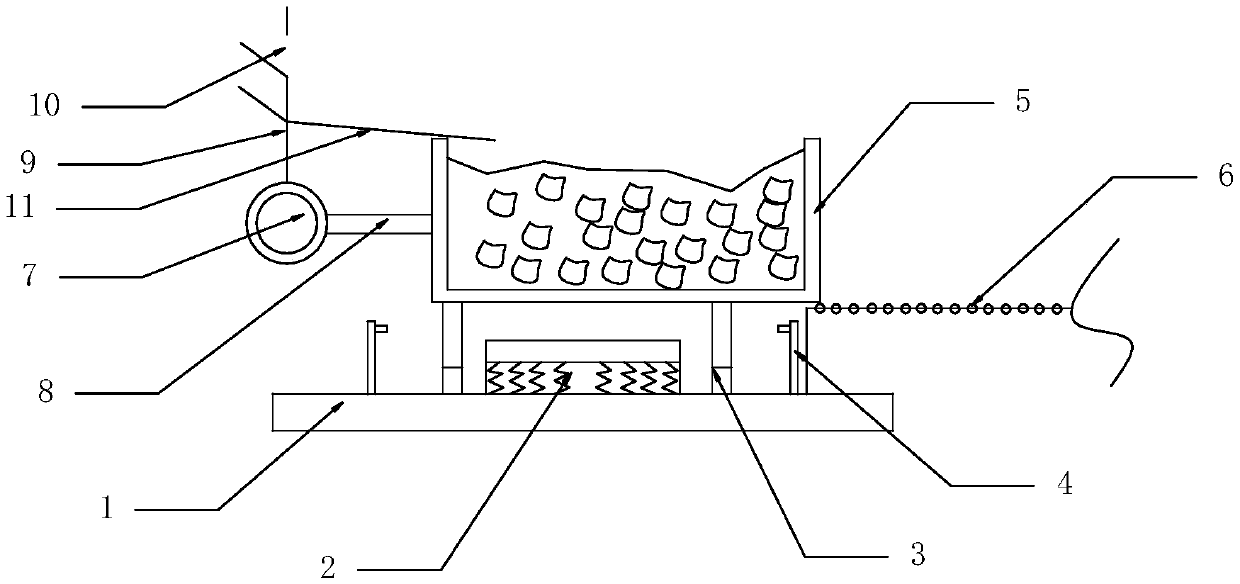

[0016] figure 1 It is the structural representation when the present invention is not connected, figure 2 It is a schematic diagram of the structure conveyed after receiving materials of the present invention, as shown in the figure: the auto parts surface treatment material receiving device of the present embodiment includes: receiving box 5: used for connecting and assembling surface-treated auto parts; Column 3: used for lifting and lowering the receiving box 5; elastic placement table 2: providing elastic support for the receiving box 5 when receiving materials; limit column 4: used to limit the receiving box 5 when receiving materials for the receiving box 5 Movement in the horizontal direction; transfer mechanism 6: transfer the receiving box 5 full of parts to the next station; push rod 8: push the receiving box 5 full of parts to the transfer mechanism 6; The material box 5 is placed on the elastic placing platform 2; the elastic placing platform 2 is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com