Device and method for separating olefin from Fischer-Tropsch synthetic oil

A Fischer-Tropsch synthetic oil and olefin technology, which is applied in the field of coal chemical industry, can solve the problems of high equipment operation cost, low economic value, and complicated process flow, and achieve the effects of reducing high operating cost, improving economic benefits, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

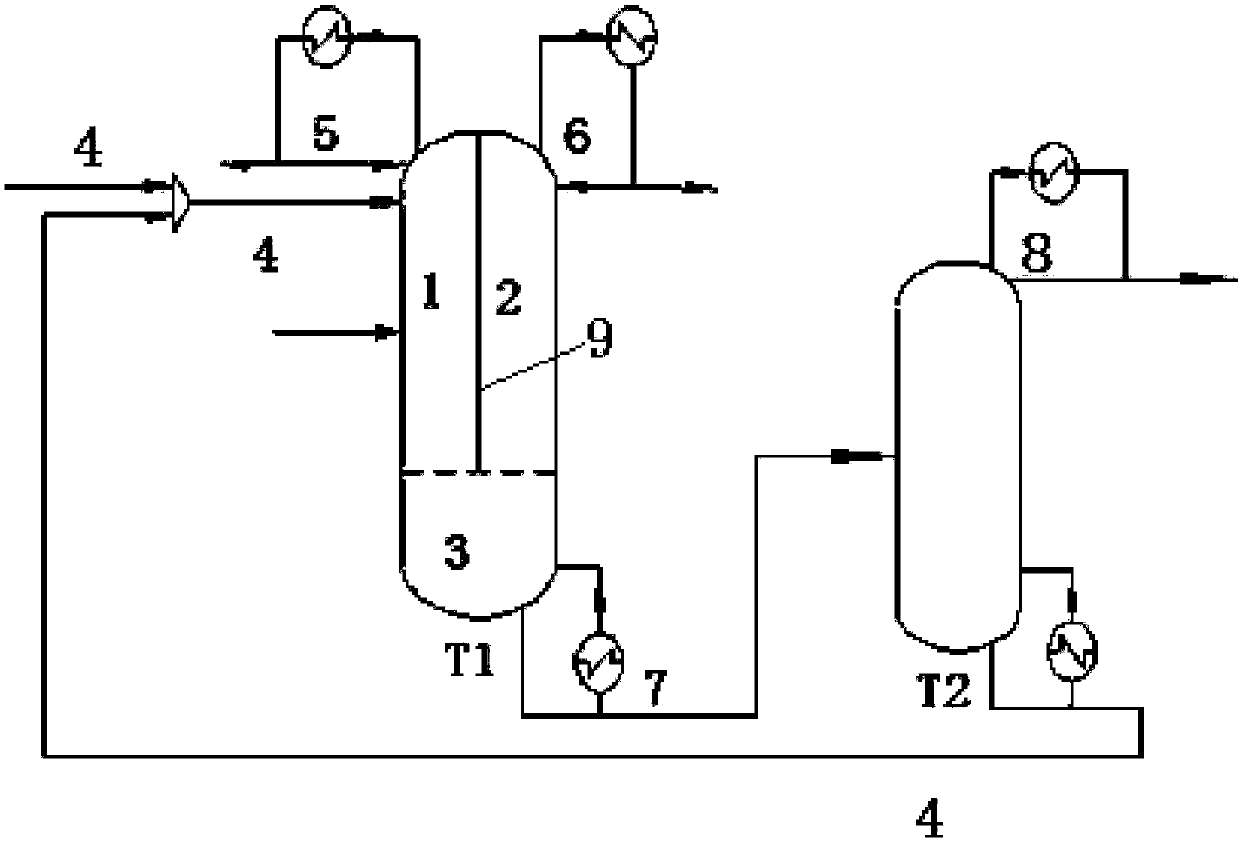

[0048] This example provides a method for separating olefins from Fischer-Tropsch synthetic oil. The method comprises the steps of:

[0049] Cut the C5 fraction from the iron-based Fischer-Tropsch synthetic oil and pass it into the extraction fraction section 1. The inlet of the C5 fraction is the dividing line, the upper section is the extraction and rectification section, and the lower section is the extraction and distillation section. The extractant 4 is passed into 1, and the olefin 6 is separated in the side rectification section 2 by using the extractant 4.

[0050] In this experimental example, the parameters of the dividing wall column T1 are selected as follows: the number of plates in the main column is 30, the reflux ratio in the main column area is 3, the temperature at the top of the column is 60°C, the temperature at the bottom of the column is 145°C, the pressure inside the column is 1 atm, and the secondary The number of plates is 25, the extractant 4 is N,N-...

Embodiment 2

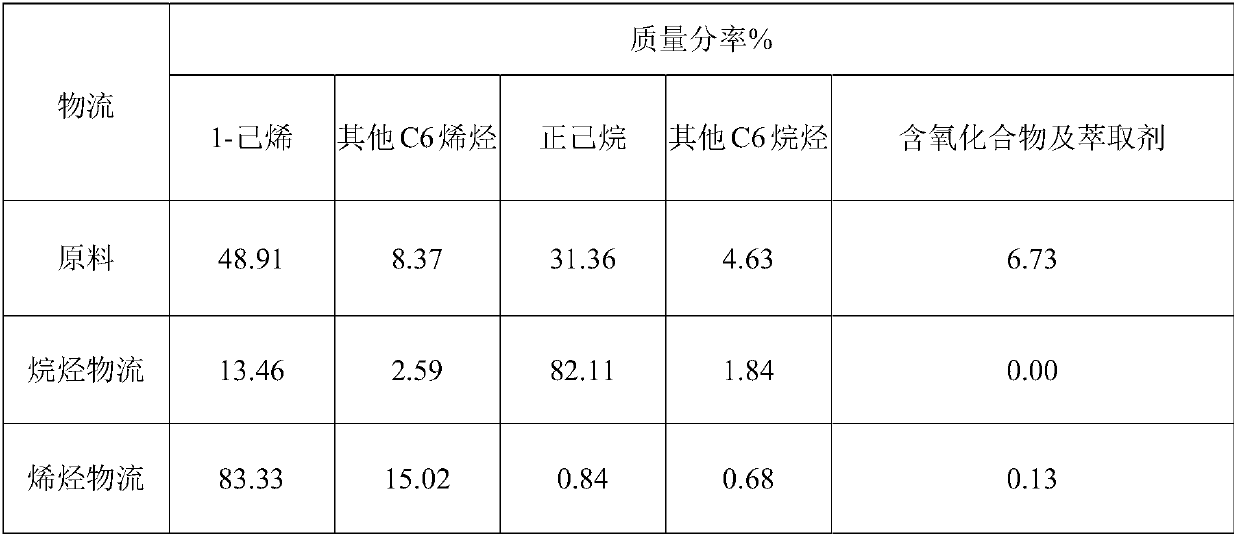

[0055] This example provides a method for separating olefins from Fischer-Tropsch synthetic oil. The method comprises the steps of: passing the C6 fraction of the iron-based Fischer-Tropsch synthetic oil into the extraction fraction section 1, the inlet of the C6 fraction is the dividing line, the upper section is the extraction and rectification section, and the lower section is the extraction and distillation section, and The extraction agent 4 is passed into the extraction fraction section 1, and the olefin 6 is separated in the side line rectification section 2 by using the extraction agent 4. In this experimental example, the number of trays in the main tower is 60, the reflux ratio in the main tower area is 2, the temperature at the top of the tower is 106°C, the temperature at the bottom of the tower is 192°C, the pressure inside the tower is 3 atm, and the number of trays in the side line rectification section is is 40, the extractant 4 is N-methylpyrrolidone, and the ...

Embodiment 3

[0061] This example provides a method for separating olefins from Fischer-Tropsch synthetic oil. The method comprises the following steps: passing the C7 fraction cut from the iron-based Fischer-Tropsch synthetic oil into the extraction fraction section 1, the inlet of the C7 fraction is the dividing line, the upper section is the extractive distillation section, and the lower section is the extraction section 1. Distillation section, and the extraction agent 4 is passed into the extraction fraction section 1, and the olefin 6 is separated in the side rectification section 2 by using the extraction agent 4.

[0062] In this experimental example, the number of trays in the main tower is 60, the reflux ratio in the main tower area is 3, the temperature at the top of the tower is 139°C, the temperature at the bottom of the tower is 242°C, the pressure inside the tower is 3atm, and the number of trays in the auxiliary tower is 40 , the extractant 4 is N-methylpyrrolidone; the mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com