A method for rapid preparation of copper/polytetrafluoroethylene superamphiphobic coating

A polytetrafluoroethylene, super-amphiphobic technology, used in coatings, antifouling/underwater coatings, anti-corrosion coatings, etc., can solve the problem of poor coating uniformity and substrate adhesion, unsuitable for large-scale industrial applications Complex control conditions, etc., to achieve the effects of high controllability, increased popularization and application, and direct process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0034] (1) Select a 6061 aluminum alloy with a size of 20×40×2mm as the base sample, polish the base sample smoothly with sandpaper, and put the polished sample into acetone and absolute ethanol for 5 minutes for ultrasonic cleaning, To remove grease and pollutants on the surface of the sample;

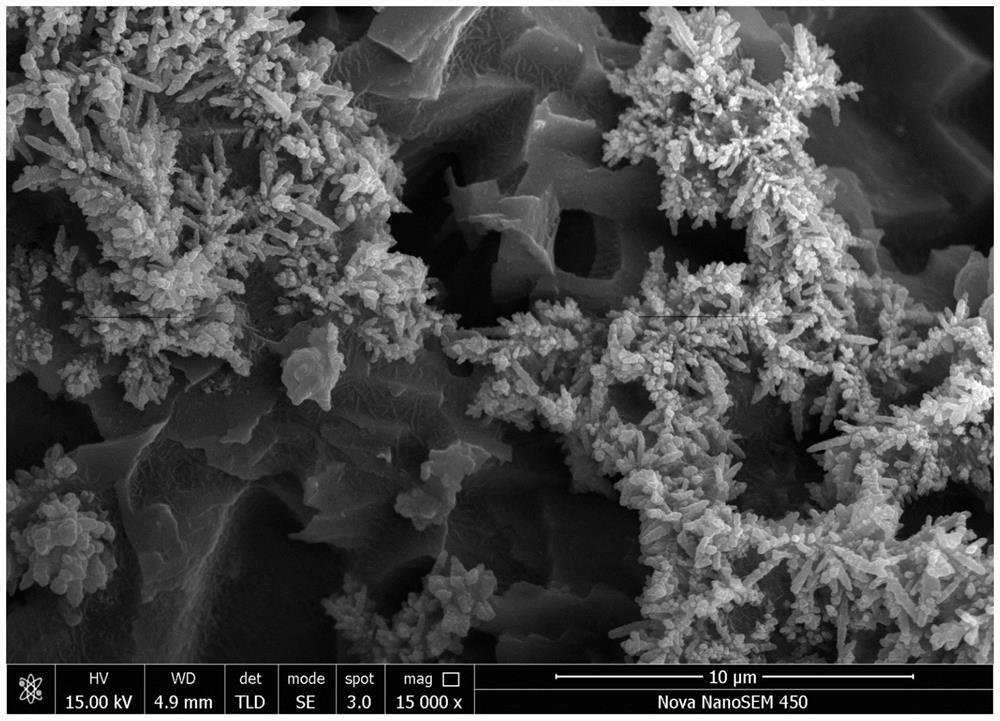

[0035] (2) The above-mentioned cleaned 6061 aluminum alloy sample is prepared by dipping into a membrane (parts by mass: 10 parts of copper sulfate pentahydrate, 1 part of sodium chloride, 50 parts of deionized water (pure water), water-soluble PTFE emulsion 20 parts) in the chemical displacement membrane-making emulsion, the immersion time is 4min, generates partial reddish Cu / PTFE composite coating on the surface of the base material, and takes it out for subsequent use;

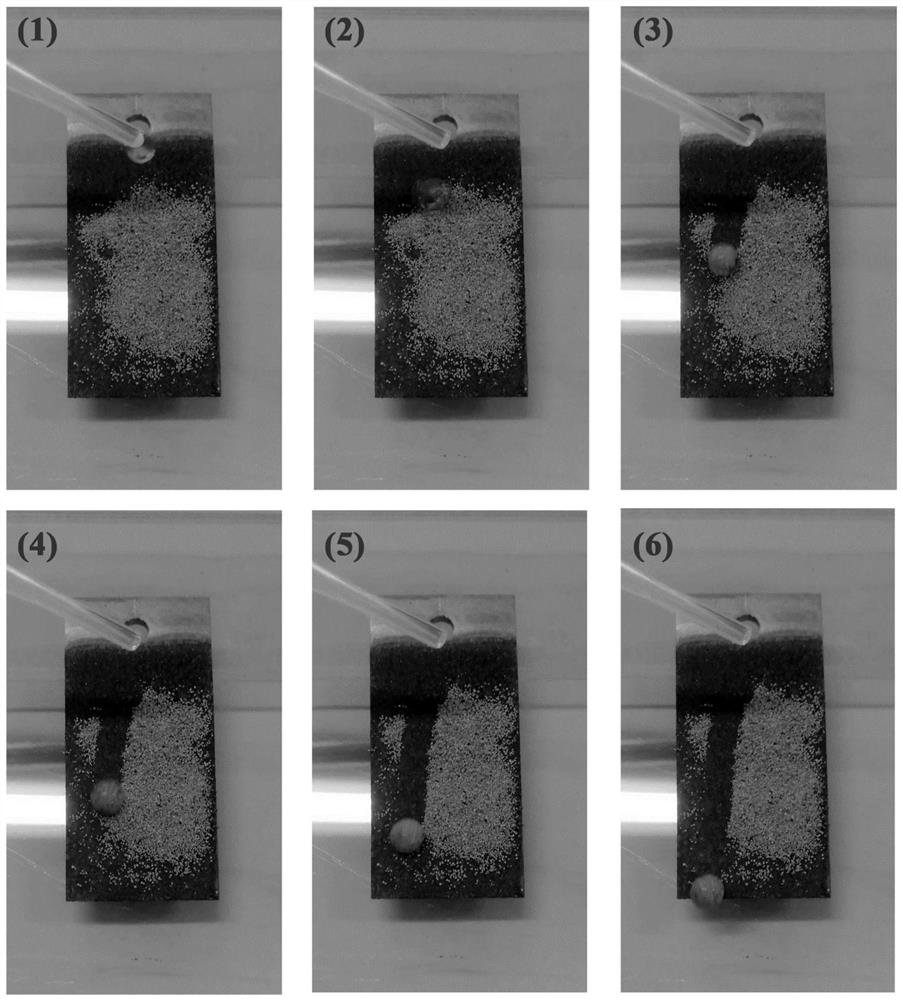

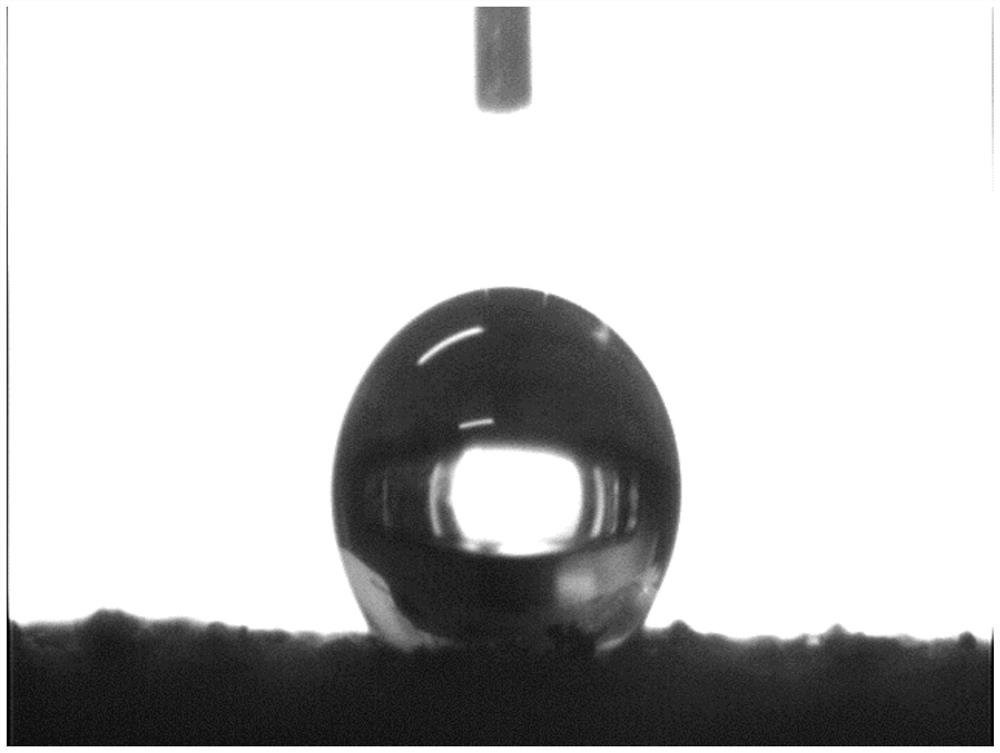

[0036] (3) Put the substrate sample covered with Cu / PTFE composite coating in the previous step into a vacuum tube furnace for direct heat treatment. The vacuum degree in the furnace is figure 1 Shown), it is self...

specific Embodiment approach 2

[0039] (1) Select a 6061 aluminum alloy with a size of 20×40×2mm as the base sample, polish the base sample smoothly with sandpaper, wash it with 3% sodium hydroxide alkaline water for 2 minutes, and put the polished Put the sample into acetone and absolute ethanol in sequence for 10 minutes of ultrasonic cleaning to remove the grease and pollutants on the surface of the sample;

[0040] (2) The above-mentioned cleaned 6061 aluminum alloy sample was prepared by dipping into a membrane (parts by mass: 20 parts of copper sulfate pentahydrate, 1.5 parts of sodium chloride, 100 parts of deionized water (pure water), water-soluble PTFE emulsion 30 parts) in the chemical displacement film-making emulsion, the immersion time is 3min, generates partial reddish Cu / PTFE composite coating on the base material surface, and it is standby after taking out;

[0041] (3) Put the substrate sample covered with Cu / PTFE composite coating in the previous step into the muffle furnace for direct hea...

specific Embodiment approach 3

[0043] (1) Select 6061 pure aluminum with a size of 20×40×2mm as the base sample, polish the base sample smoothly with sandpaper, pickle with 30% nitric acid pickling solution for 2 minutes, and polish the polished samples in turn Put it into acetone and absolute ethanol for ultrasonic cleaning for 15 minutes to remove grease and pollutants on the surface of the sample;

[0044] (2) The above-mentioned cleaned pure aluminum sample was dipped and pulled in (parts by mass: 25 parts of copper sulfate pentahydrate, 2 parts of potassium chloride, 150 parts of deionized water (pure water), 30 parts of water-soluble PTFE emulsion Parts) in the chemical displacement film-making emulsion, the immersion time is 5min, and a reddish Cu / PTFE composite coating is generated on the surface of the base material, which is taken out for subsequent use;

[0045] (3) Put the substrate sample covered with Cu / PTFE composite coating in the previous step into the muffle furnace for direct heat treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com