A method for rapid preparation of copper oxide/polytetrafluoroethylene superamphiphobic coating

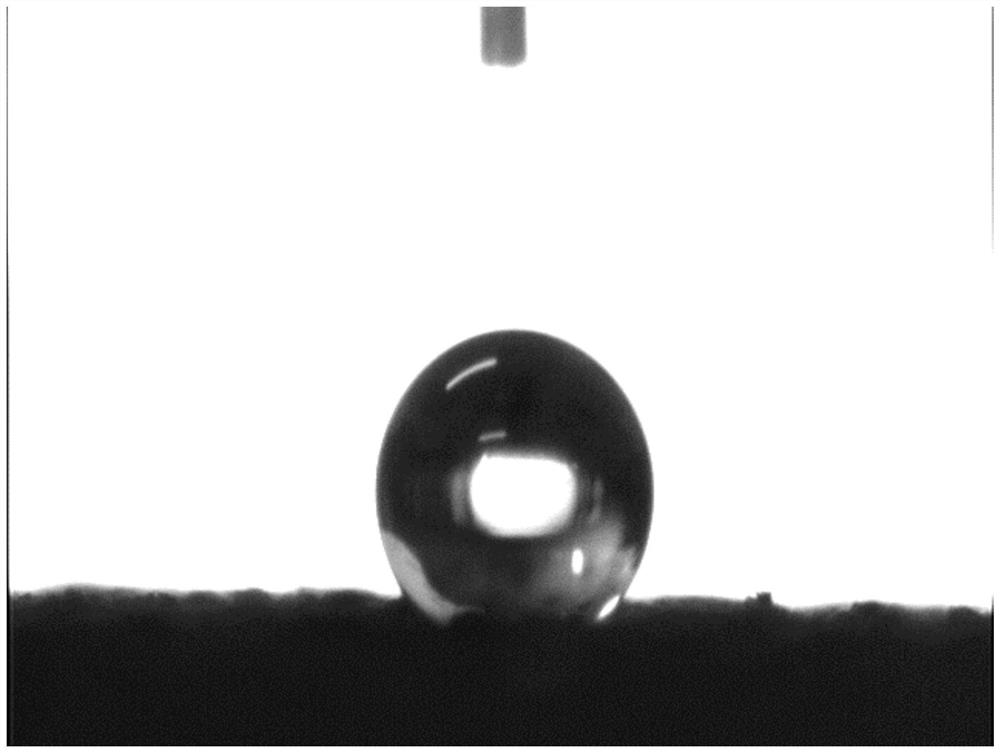

A polytetrafluoroethylene, super-amphiphobic technology, used in coatings, metal material coating processes, anti-corrosion coatings, etc., can solve the problem of poor coating uniformity and substrate bonding, unsuitable for large-scale industrial applications, process control Complex conditions and other problems, to achieve the effect of high controllability, increased popularization and application, and direct process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0035] (1) Select the 6061 aluminum alloy having a size of 20 × 40 × 2 mm as a substrate, and the substrate sample is smooth and smooth, and the polished sample is sequentially placed in acetone, anhydrous ethanol is ultrasound. 5 min. The oil and pollutants of the sample surface are removed;

[0036] (2) 6061 aluminum alloy sample described above is used in impregnating film formation method in (mass) 10 parts of pentaqueous sulfate, 1 sodium chloride, deionized water (pure water) 50 parts, water soluble PTFE emulsion 20 copies of the chemical replacement membrane emulsion, the immersion time was 4 min, and a biased Cu / PTFE composite coating was generated on the surface of the matrix material, and the retrieval was taken out;

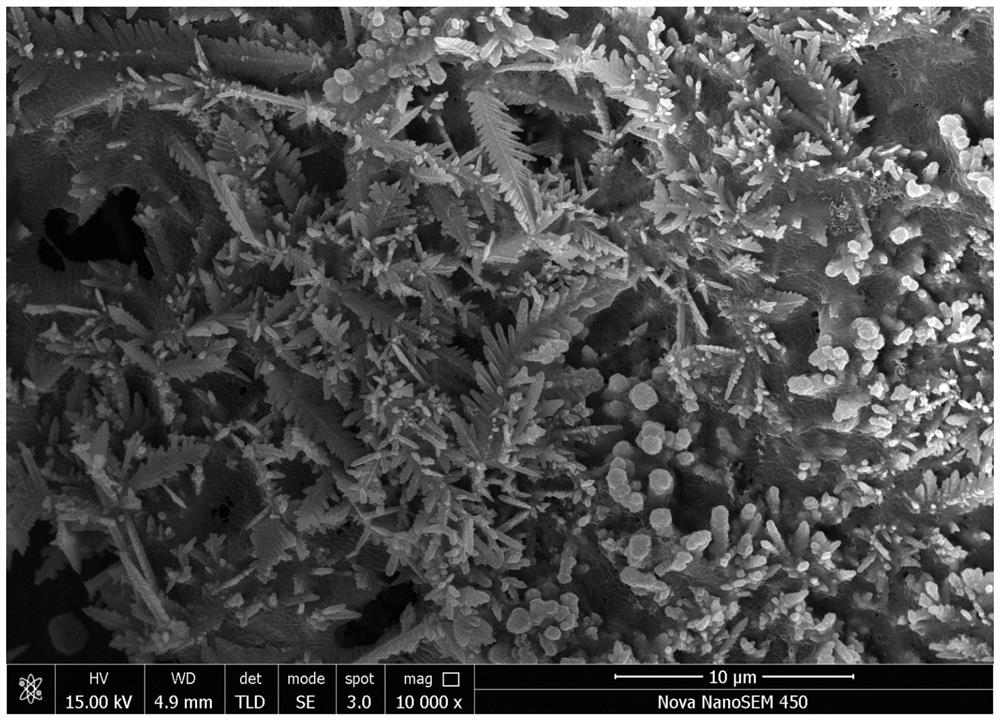

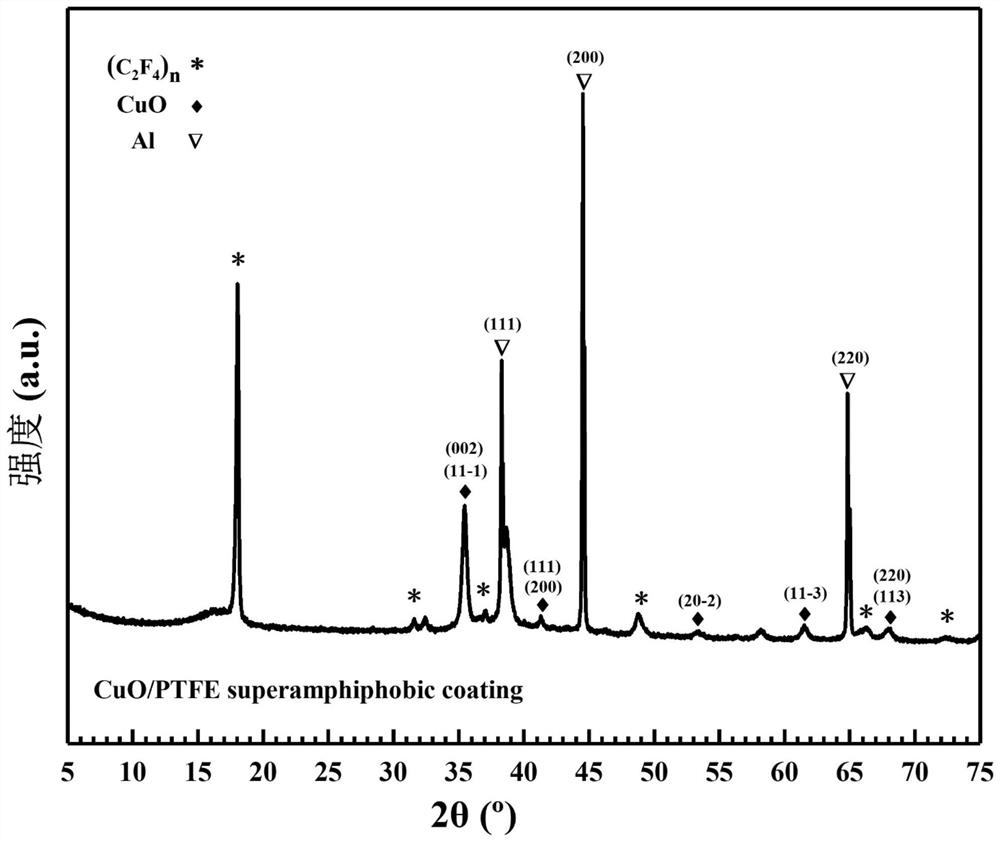

[0037] (3) The surface of the Cu / PTFE composite coating is placed in the upper surface of the Cu / PTFE composite coating is directly thermally treated, the gas atmosphere is air, the control temperature rate is 5 ° C / min, and the bia is biased on th...

specific Embodiment approach 2

[0040] (1) Select the 6061 aluminum alloy having a size of 20 × 40 × 2 mm as a substrate, and the substrate sample is smooth, and the base sample is washed 2 min in the basic water washing liquid, and will be polished. The sample is sequentially placed in acetone, ultrasonic waves in anhydrous ethanol, washed 10 min to remove grease and contaminants on the surface of the sample;

[0041] (2) 6061 aluminum alloy samples described above adopt a dip film formation method (20 parts of copper sulfate, 1.5 parts of sodium chloride, 100 parts of deionized water (pure water), water soluble PTFE emulsion 30 copies of the chemical replacement membrane emulsion, the immersion time was 3 min, and a biased Cu / PTFE composite coating was generated on the surface of the matrix material, and the post was taken out;

[0042] (3) Putting the substrate sample of the Cu / PTFE composite coating in the previous step in the muffle furnace directly to heat treatment, the gas atmosphere is air, the cont...

specific Embodiment approach 3

[0044] (1) Select 6061 pure aluminum of 20 × 40 × 2 mm to the substrate sample, and use sandpaper to smooth the substrate sample smooth, washing 2 min in the pickled liquid of 30% nitric acid, and will be polished The ultrasonic waves were placed in acetone and anhydrous ethanol for 15 min to remove grease and contaminants on the surface of the sample;

[0045] (2) The above-mentioned pure aluminum sample is made of dipping lipping method in (mass) 250 parts of copper sulfate, 2 potassium chloride, deionized water (pure water), water soluble PTFE lotion 30 Part of the chemical replacement film emulsion, the immersion time is 5 min, and a biased Cu / PTFE composite coating is generated on the surface of the matrix material, and the retrieval is removed;

[0046] (3) The surface of the Cu / PTFE composite coating is placed in the upper surface of the Cu / PTFE composite coating is directly thermally treated, the gas atmosphere is air, the control temperature rate is 5 ° C / min, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com