A kind of activated carbon fiber low temperature pre-oxidation equipment

An activated carbon fiber, low temperature technology, applied in the field of carbon fiber processing, can solve the problems of poor thermal insulation effect, energy consumption, waste of resources, etc., and achieve the effects of saving manufacturing costs, rationally utilizing energy, and rationally utilizing energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

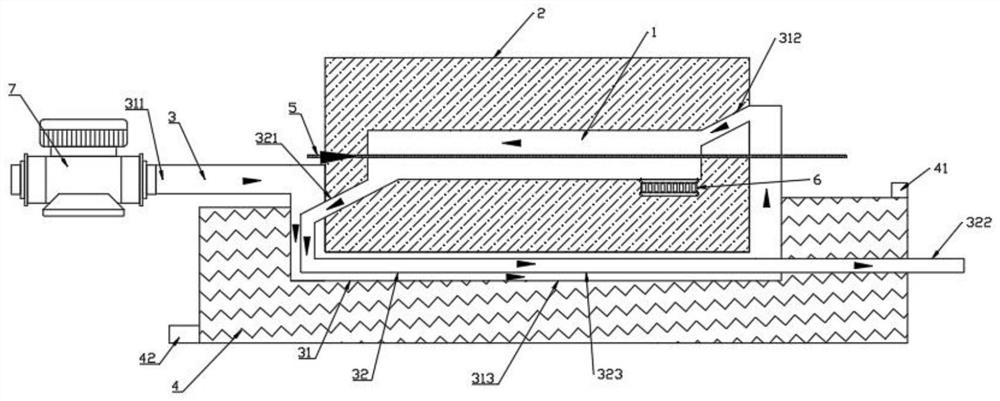

[0019] Such as figure 1 As shown, the activated carbon fiber low-temperature pre-oxygenation equipment provided in this embodiment includes a carbonization bin 1, a carbon fiber bundle 5, and a gas transportation pipeline 3. The gas transportation pipeline 3 includes a gas transportation pipe 31 and an exhaust gas transportation pipe 32. The carbonization bin 1 is embedded in a compartment In the thermal insulation box 2, a gas transportation pipe 31 is provided on one side of the carbonization chamber 1, and a waste gas transportation pipe 32 is connected to the other side of the carbonization chamber 1. The hot air blower 6 and the waste gas transport pipe 32 pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com