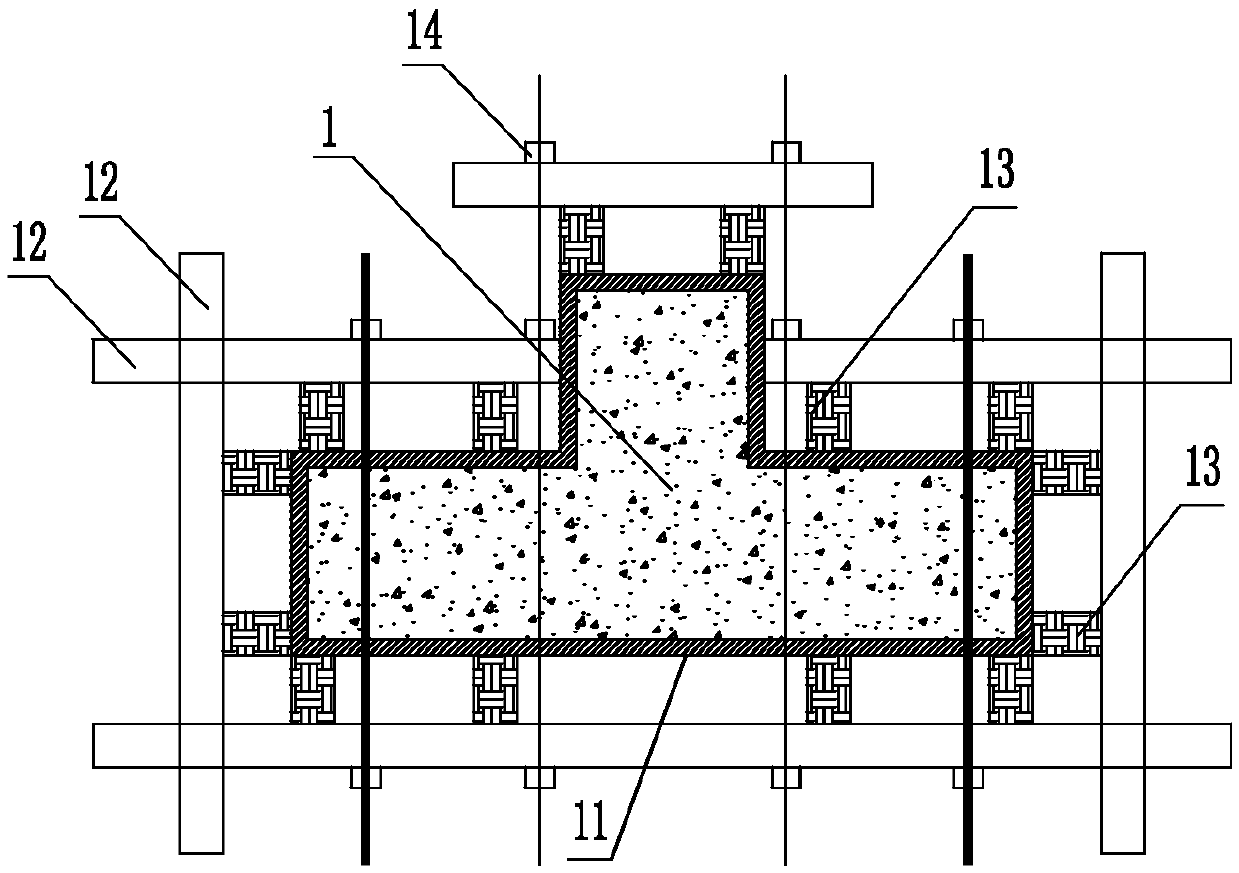

Concrete small-cross section special-shaped column mould box method construction method

A construction method and special-shaped column technology, applied in the direction of formwork/formwork/work frame, column, pier column, etc., can solve the problems of support deformation, change of component section size, easy extrusion deformation of formwork, etc. The effect of saving construction costs and saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] A concrete small-section special-shaped column mold box method construction method, the construction method comprises the following steps:

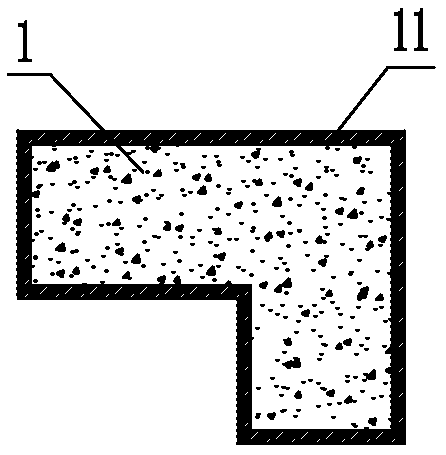

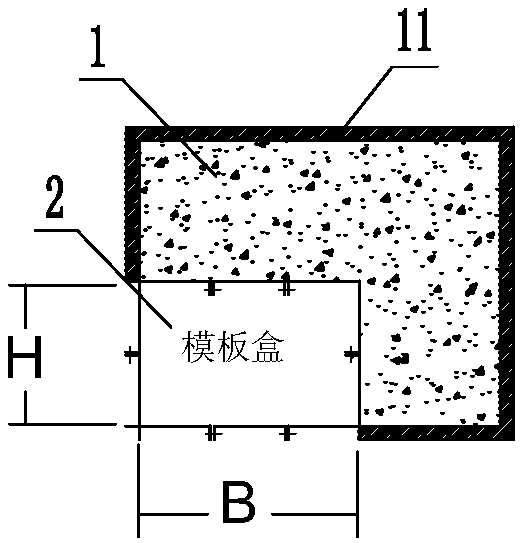

[0071] S1. Deepen the design and determine the type, quantity and cross-sectional size of the formwork boxes that need to be added to transform the special-shaped column into a "rectangular column";

[0072] S11. Based on the floor plan of small-section concrete special-shaped columns, use BIM technology to model, and count the types and quantities of formwork boxes required, as well as the cross-sectional dimensions B and H of the formwork boxes, where B is the length of the formwork box, and H is The width of the template box, the height of each template box is 200mm;

[0073] S12. According to the statistical results of step S11, according to the actual situation of the construction site, prepare a special construction plan for small-section concrete special-shaped columns, and submit it for approval;

[0074] S2. Make template...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com