Radial wheel edge sealing structure with internal splines

A sealing structure and radial sealing technology, which is applied in the direction of preventing leakage, engine components, machines/engines, etc., can solve problems such as limited effects, and achieve the effects of improving sealing performance, enhancing mixing strength, and improving heat transfer stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and technical principles.

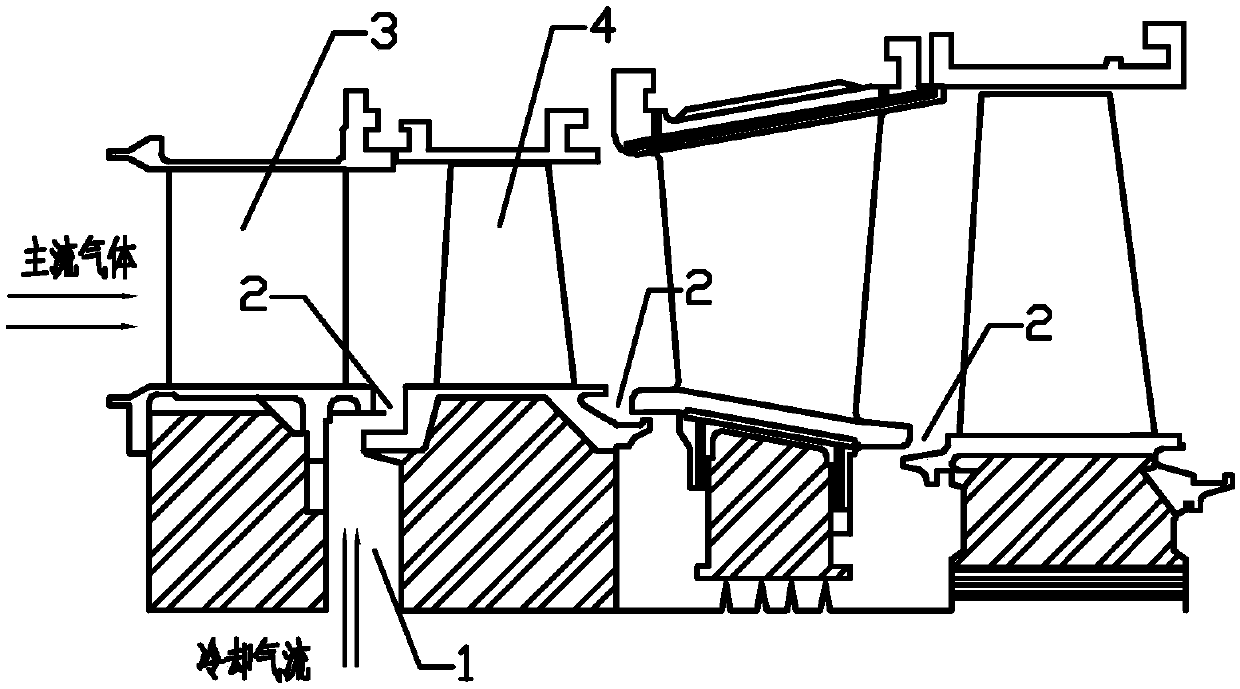

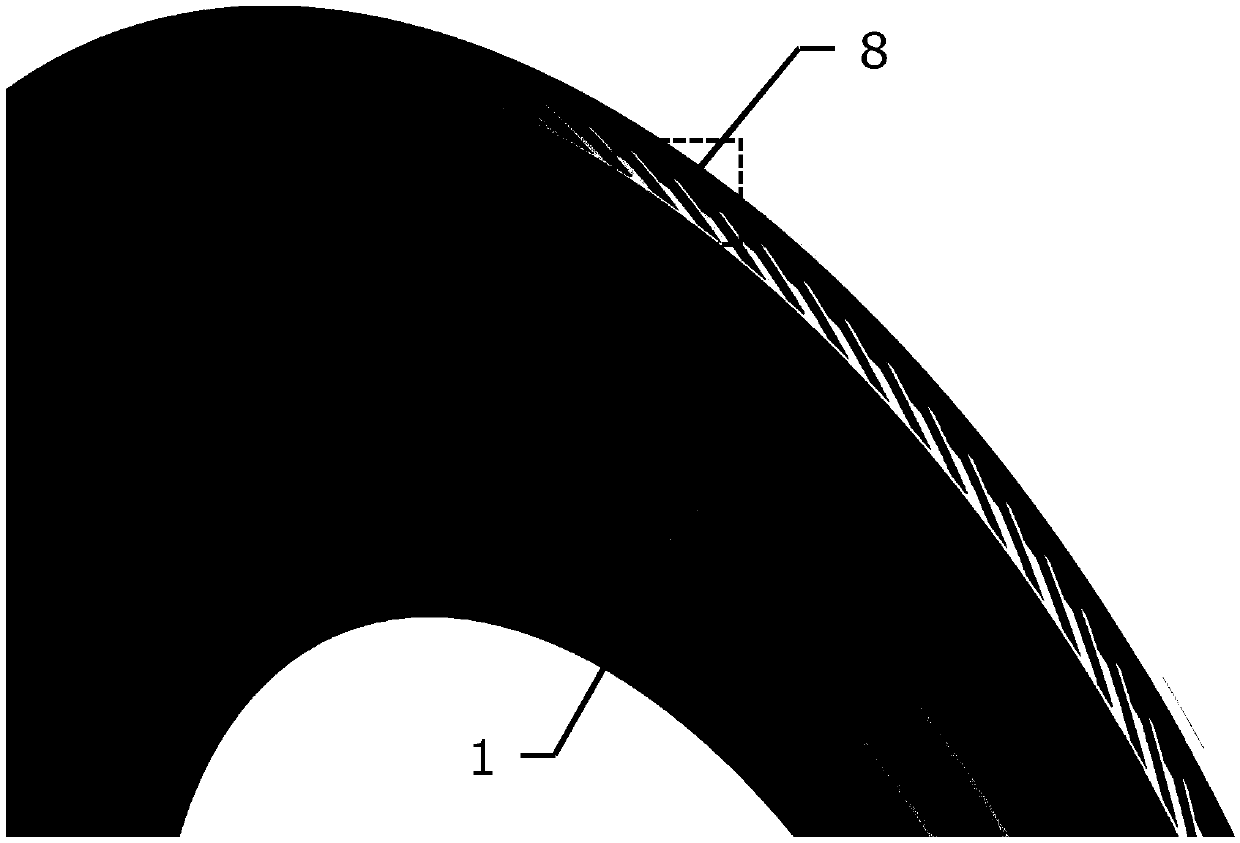

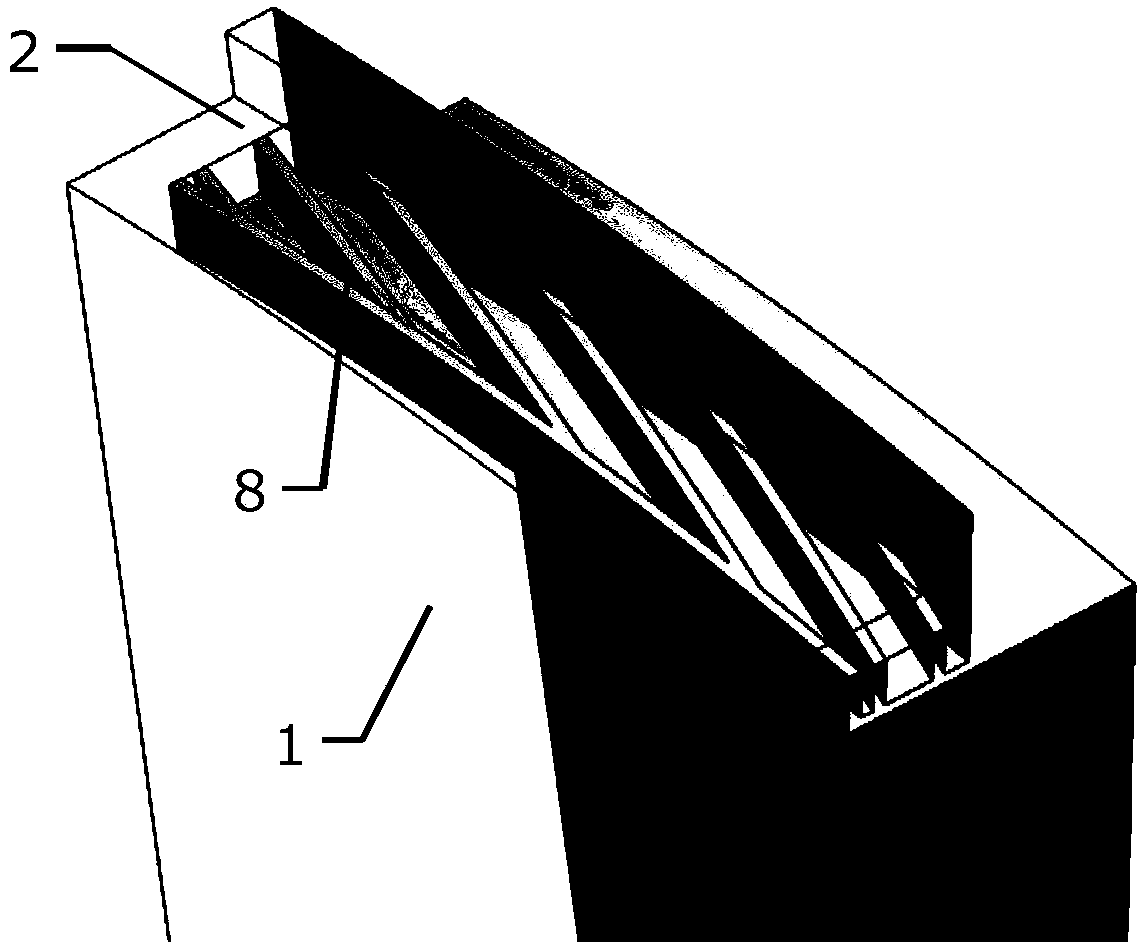

[0032] see figure 1 5, the present invention provides a radial rim seal structure with internal tooth grooves, the radial rim seal structure 2 is arranged in the gas turbine rotary-static disc cavity 1, and includes radial seals that cooperate with each other. The outer teeth 5 and the radially sealed inner teeth 6; wherein, a plurality of inner tooth slots 8 are evenly opened on the upper end surface 7 of the inner teeth of the radially sealed inner teeth 6; when the inclination angle 16 of the inner tooth slot is 0°, the inner teeth The slot 8 is a circumferential slot. When the inclination angle 16 of the inner cogging is 90°, the inner cogging 8 is an axial slot. When the inclination angle 16 of the inner cogging is between 0° and 90°, the inner cogging 8 is Oblique groove, the direction of the groove is consistent with the direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com