Distributed heat supply network energy storage pressure stabilizing system

A heat network and voltage stabilizing technology, which is applied in heating systems, hot water central heating systems, household heating, etc., can solve equipment damage, water hammer of heat network heat exchangers, and cannot meet the requirements of instantaneous super large water replenishment and other issues to achieve the effect of avoiding harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

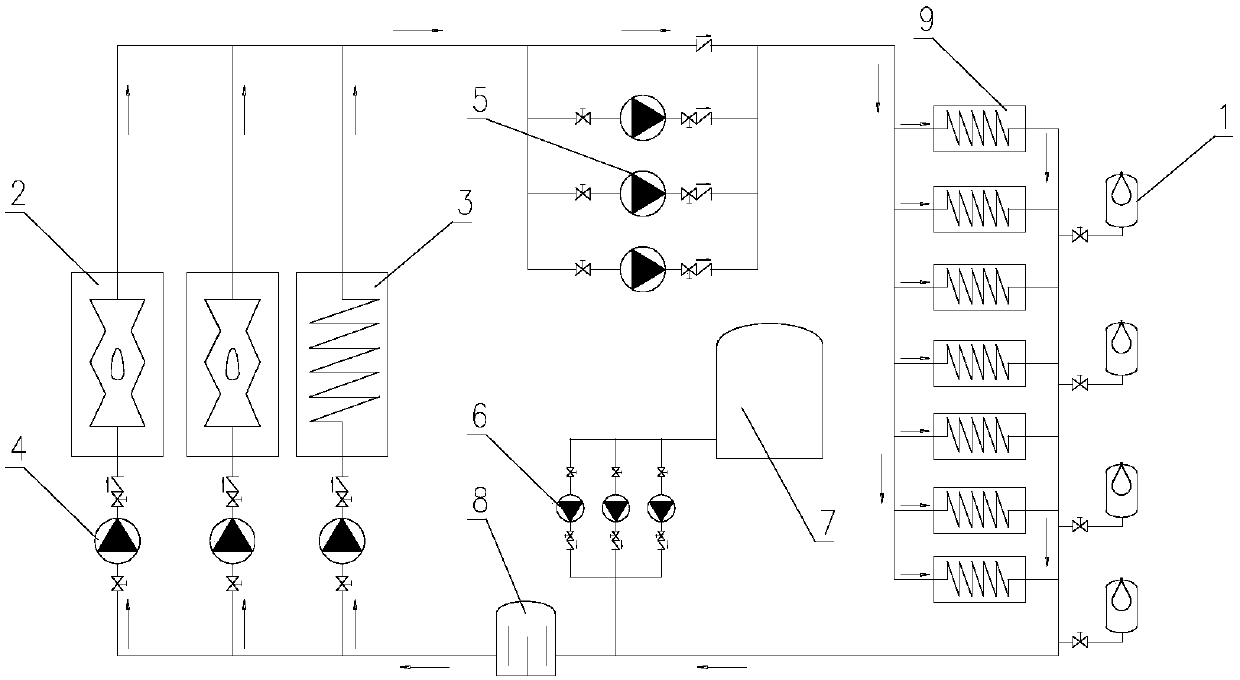

[0009] Such as figure 1 As shown, a distributed heat network energy storage and voltage stabilization system consists of a pneumatic energy storage tank 1, a hot water boiler 2, a heat network heat exchanger 3, a pre-pump 4, a heat network circulation pump 5, and a heat network replenishment pump 6 , softening water tank 7, heat network decontamination device 8 and off-site heat network heat exchanger 9, the inlet side of hot water boiler 2 and heat network heat exchanger 3 are respectively equipped with front pump 4 and 3 heat network circulation pumps 5 After parallel connection, it is connected with the outlet main pipe installed on the hot water boiler 2 and the heat network heat exchanger 3. The water outlet is connected with the water return main pipe of the heat network, the water return main pipe of the heat network is connected with the inlet of the decontamination device 8 of the heat network, and the air pressure energy storage tank 1 is connected with the water out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com