Axial flexible low-temperature heat conduction radial heat insulation device

A flexible, low-temperature technology, used in household refrigeration equipment, lighting and heating equipment, household appliances, etc., can solve the problem of low axial heat conduction efficiency, large radial heat transfer loss, and inability to adapt to the axial and radial adjustment of the heat transfer mechanism. Displacement occasions and other issues to achieve the effect of meeting the requirements of the working temperature zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific embodiments and drawings.

[0022] The purpose of the present invention is to solve the problems of low axial heat transfer efficiency and large radial heat transfer loss in the low temperature heat transfer process. In particular, it solves the problem that the rigid connection of the traditional low-temperature heat transfer mechanism has no axial and radial position and attitude adjustment, and achieves the purpose of not only meeting the requirements of low-temperature heat transfer, but also meeting the position and attitude adjustment.

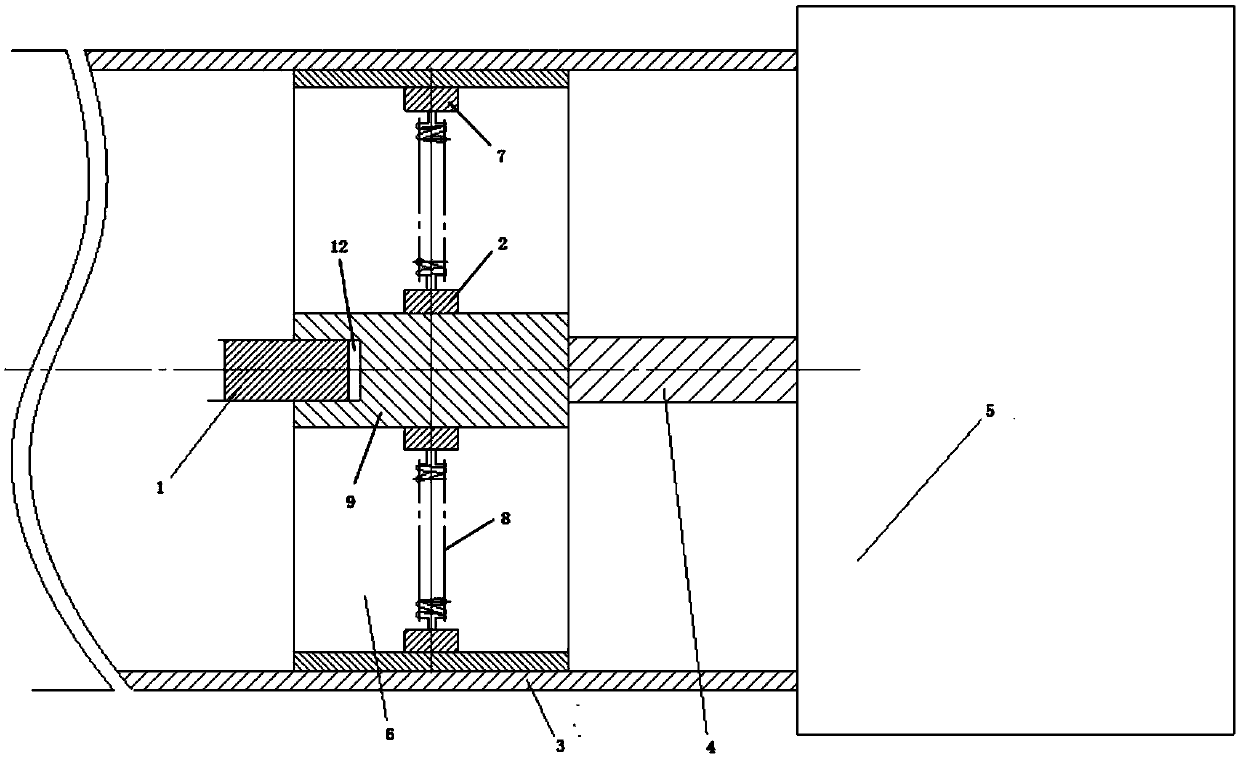

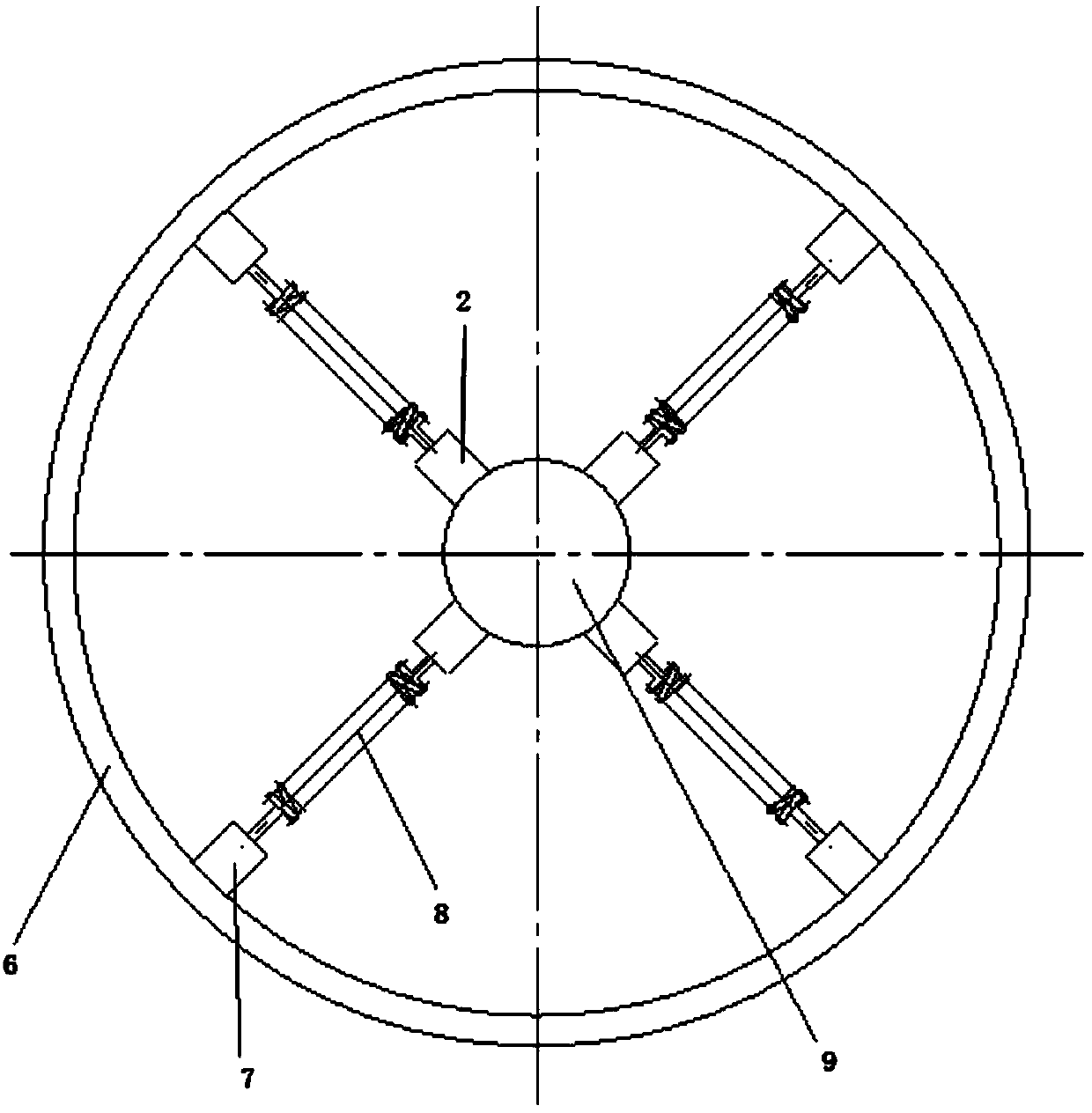

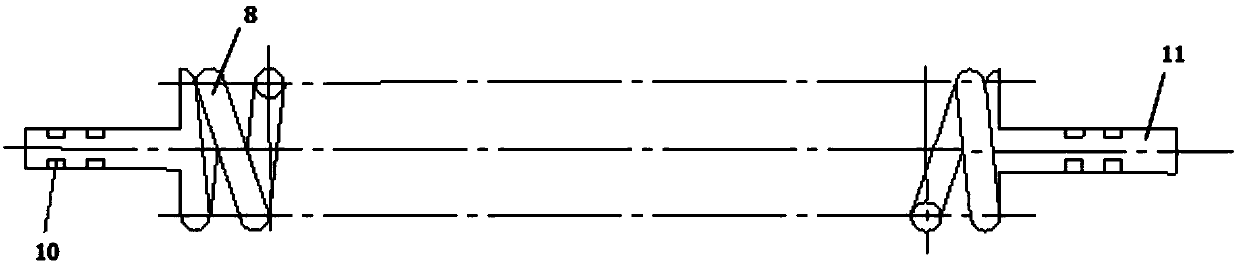

[0023] Such as Figure 1 to Figure 3 As shown, an axially flexible low-temperature thermal conduction and radial thermal insulation device includes a sealing body, an adiabatic cold chain connection structure, and a low-temperature system. The adiabatic cold chain connection structure includes an axial flexible low-temperature thermal conduction structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com