Internal peep monitoring system applied to high-temperature and high-pressure environment

A technology of high temperature and high pressure and monitoring system, applied in the field of coal gasification, can solve the problems of inability to use and limit the scope of application, and achieve the effect of ensuring safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

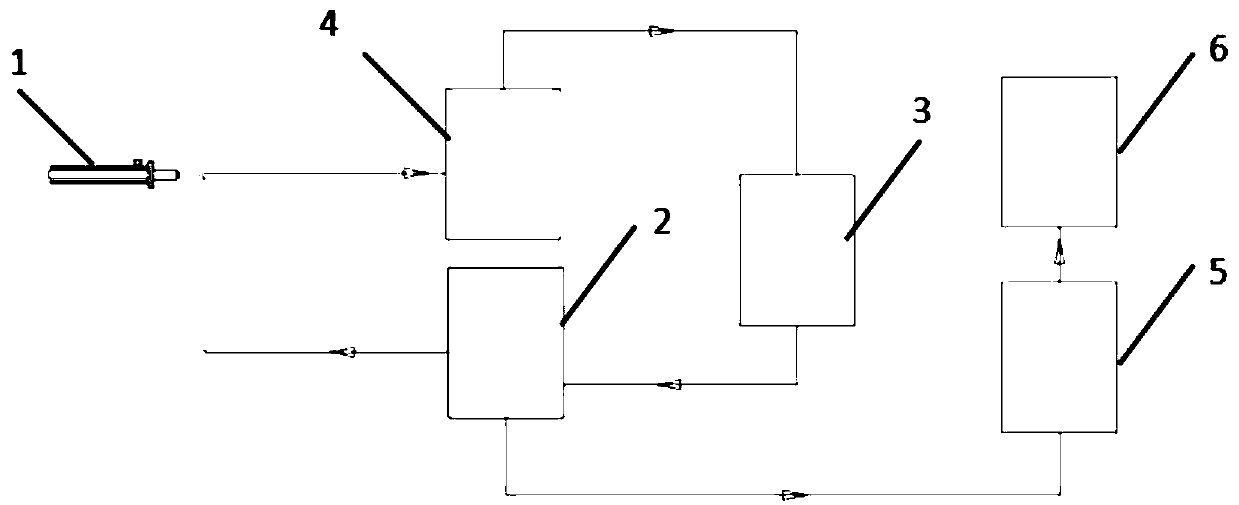

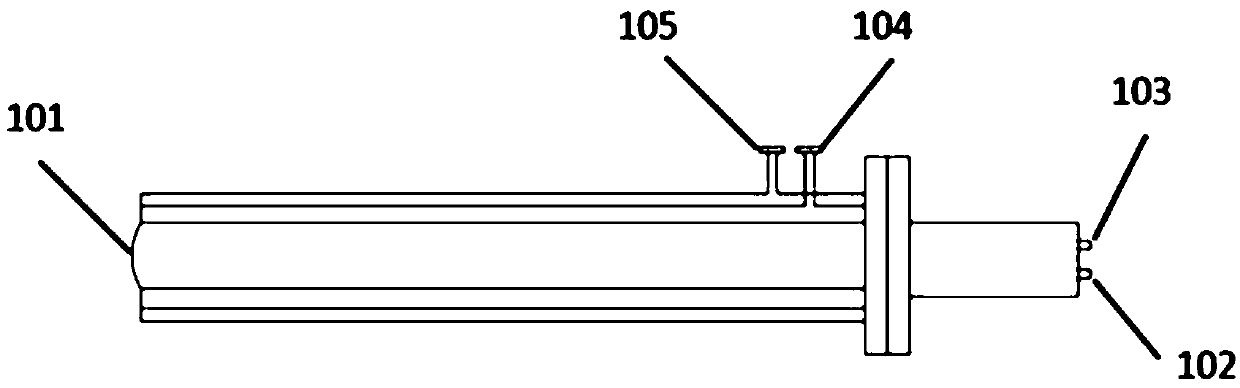

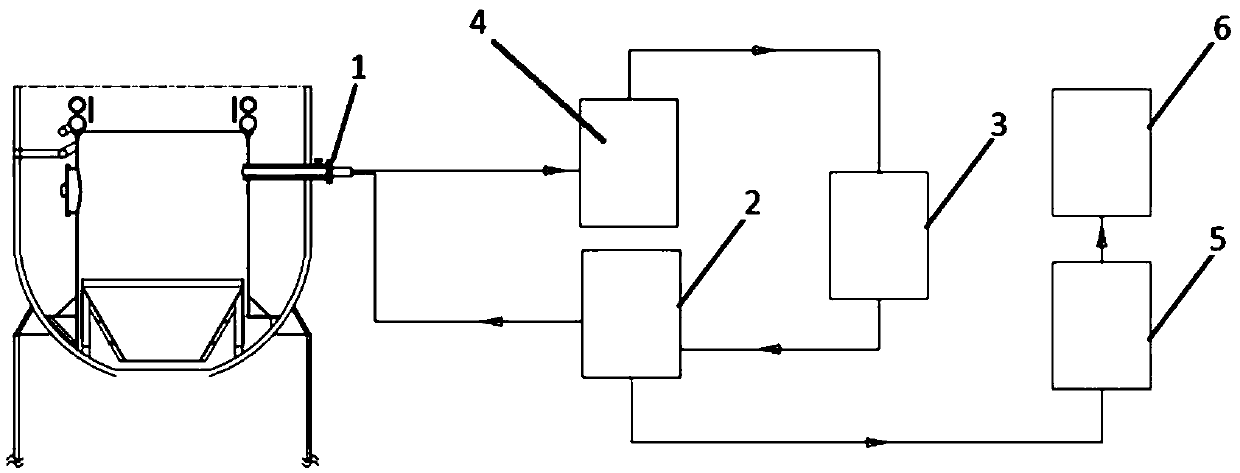

[0019] refer to figure 1 and figure 2 , the endoscopic monitoring system applied in the high temperature and high pressure environment of the present invention includes an optical transmitter 2, a server 6, a decoder 3 and a monitoring probe 1 for detecting images of molten ash in the furnace; the monitoring probe 1 It includes a casing and a monitor 101 arranged in the casing, wherein a cooling circulating water pipe is arranged on the outer wall of the monitor 101, and a protective nitrogen gas port 105 and a cooling circulating water port 104 communicated with the cooling circulating water pipe are arranged on the casing , the monitor 101 is provided with a signal output connector 103 and a signal source connector 102, wherein the signal output connector 103 is connected to the input end of the decoder 3, and the output end of the decoder 3 is connected to the inp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com