Construction method of robot terminal performance prediction model based on ga-rbf network

A technology of RBF network and performance prediction, applied in genetic models, instruments, genetic rules, etc., can solve the problems of no test steps, test stays, and no relatively systematic robot test specifications, etc., achieving good consistency and low probability of error , the effect of small error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

[0036] The robot terminal performance testing method based on GA-RBF network of the present invention comprises:

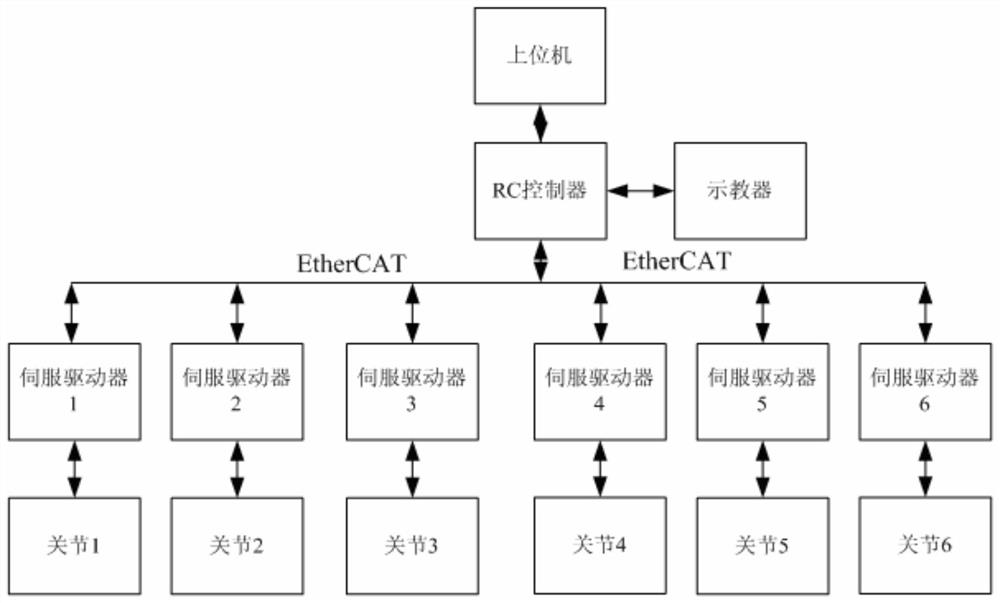

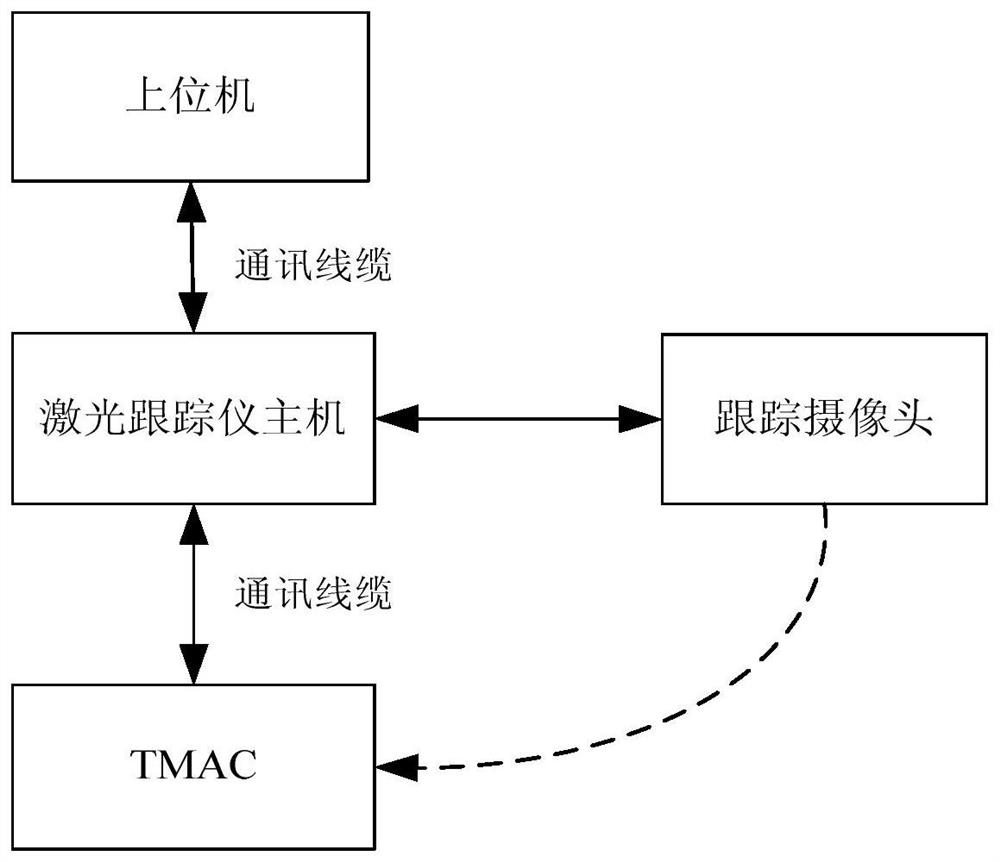

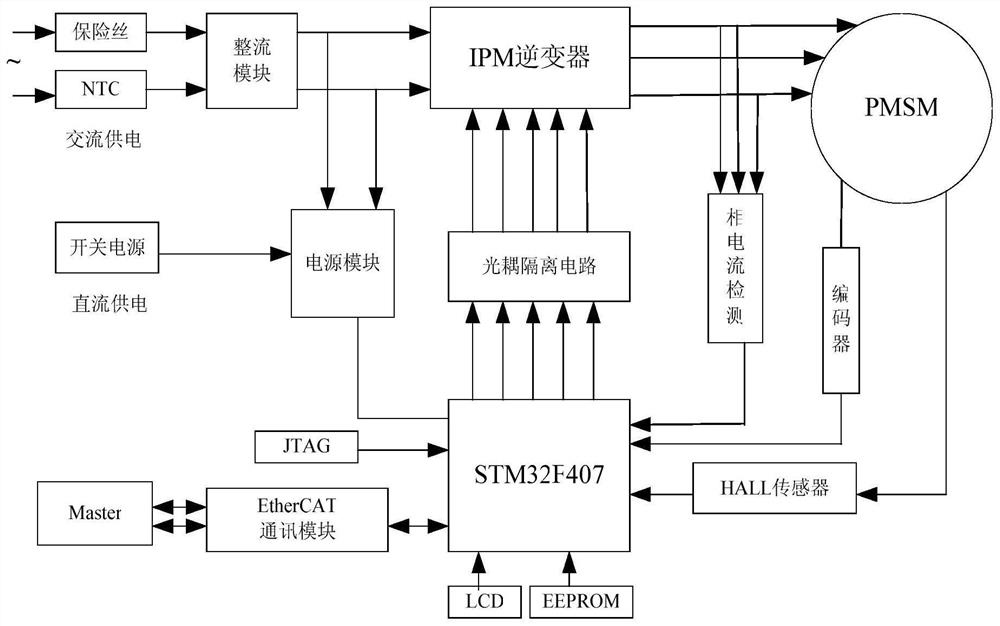

[0037] (1) Build the axis joint acquisition hardware platform for robot end data acquisition, use EtherCAT bus and laser tracker as auxiliary tools for end test, and respectively as the input and output data acquisition methods for training GA-RBF network;

[0038] (2) The position, speed, and torque feedback of each joint are collected in real time through the EtherCAT bus to obtain data as the input of the GA-RBF network, and the terminal data collected by the laser tracking coordinate measurement system are used as the output of the GA-RBF network, and the training based on the GA-RBF network Robot End Performance Prediction Model for RBF Networks.

[0039] The robot terminal performance test method based on GA-RBF netwo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com