Industrial production process fault diagnosis method based on data driving

A technology for industrial production and fault diagnosis, applied in data processing applications, instruments, calculations, etc., can solve the problems of low efficiency of diagnostic algorithm parameter optimization and large deviation of diagnostic results, etc., to improve diagnostic accuracy, improve stability, and improve adaptability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The data set of the embodiment of the present invention 1 is from the industrial production process data of a certain chemical company in the process industry. Through the following steps, the industrial production process fault diagnosis is carried out:

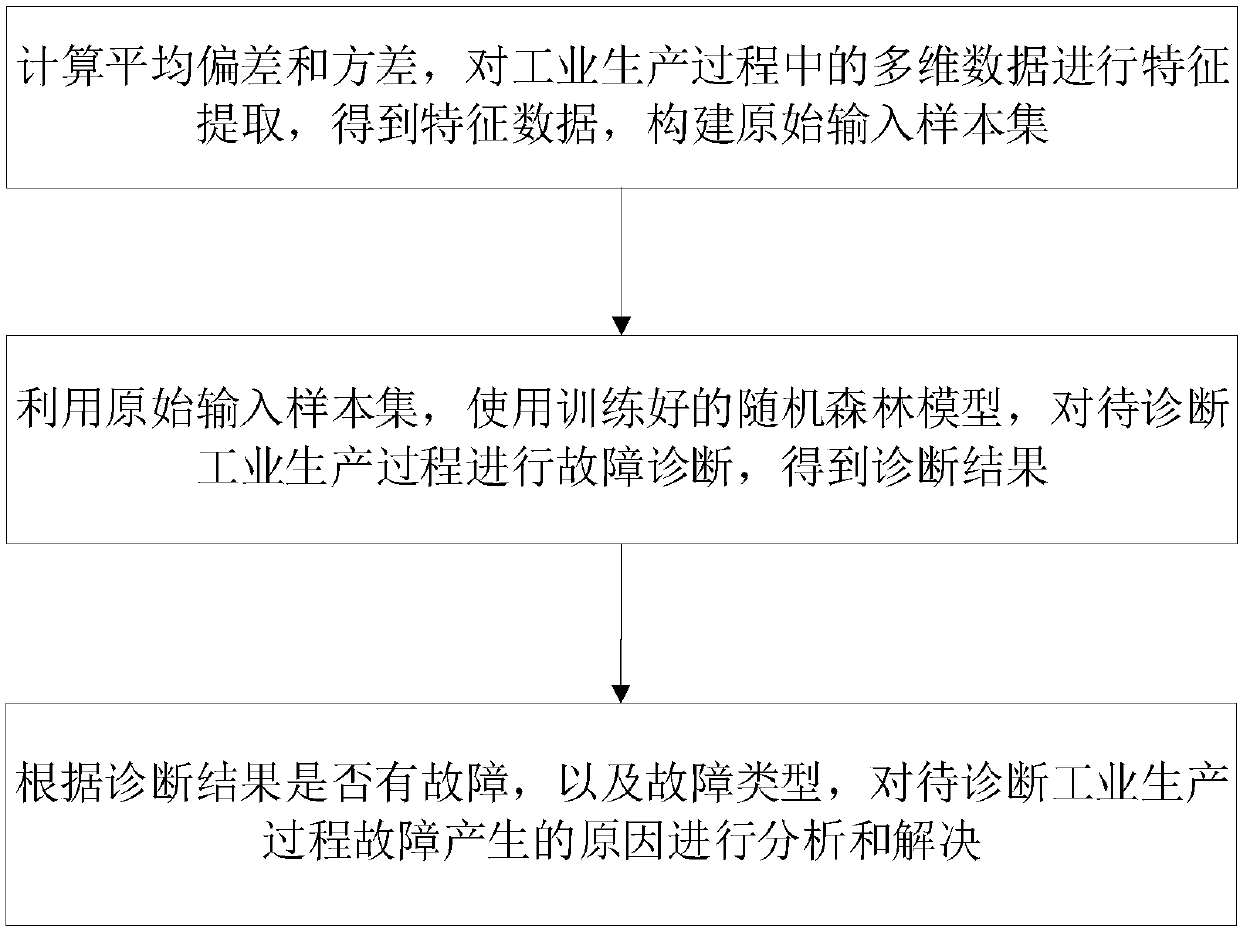

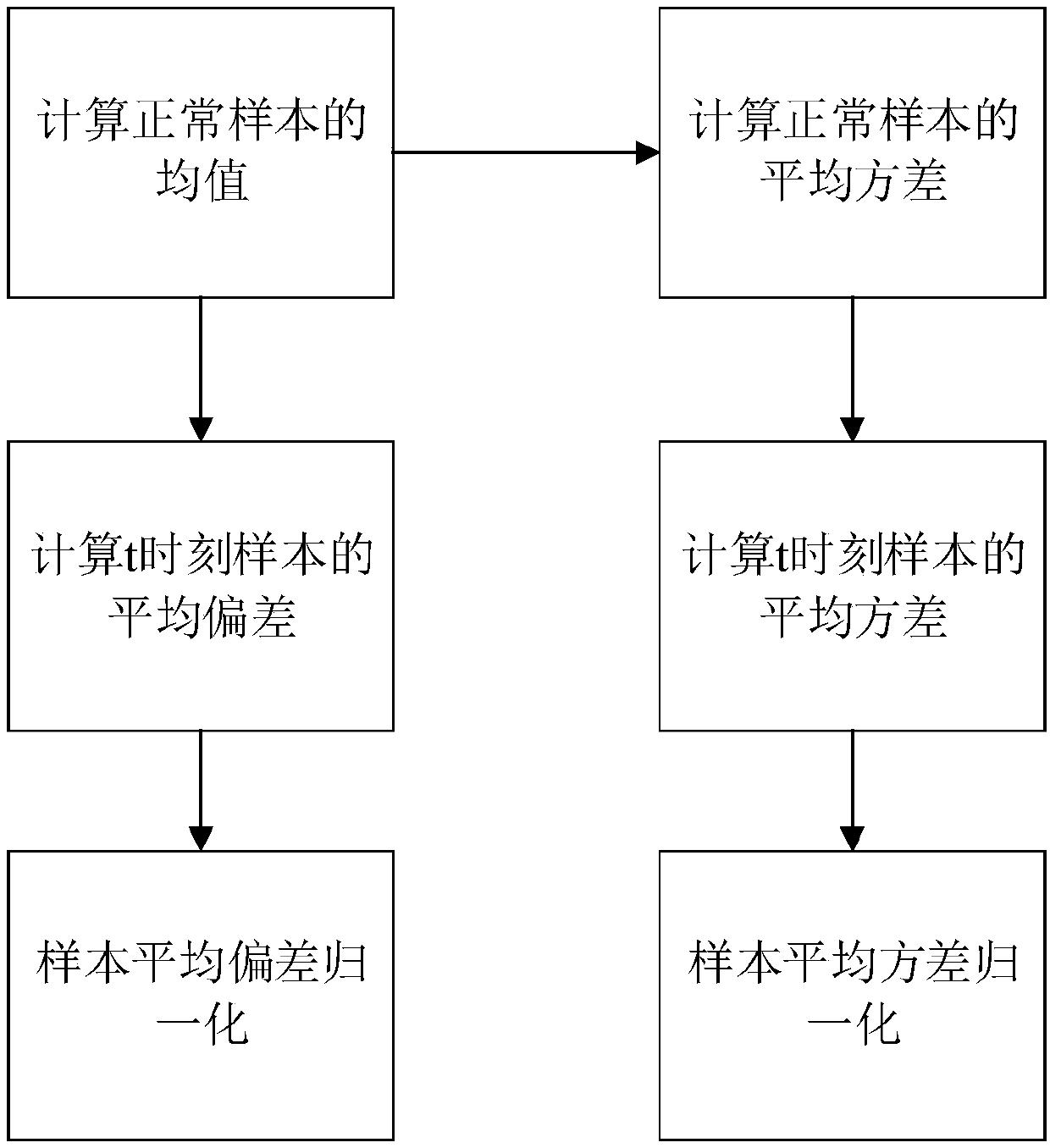

[0040] Step (1) Calculate the average deviation and variance, perform feature extraction on the multi-dimensional data in the industrial production process, obtain feature data, and construct the original input sample set. figure 2 The processing flow chart of the dynamic mean deviation and variance method is given. Specifically include the following steps:

[0041] (1.1) First calculate the sample mean and variance in the normal state, the calculation formula is as follows:

[0042]

[0043]

[0044] Among them, M k and S k Represent the mean and variance of the kth variable in the industrial production process, v i,k Represents the k-th variable value of the i-th sample, N represents the total number of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com