A Broadband Piezoelectric Energy Harvesting Method for Rotating Machinery

A technology of rotating machinery and piezoelectric energy, which is applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., and can solve problems such as frequent maintenance and frequent maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

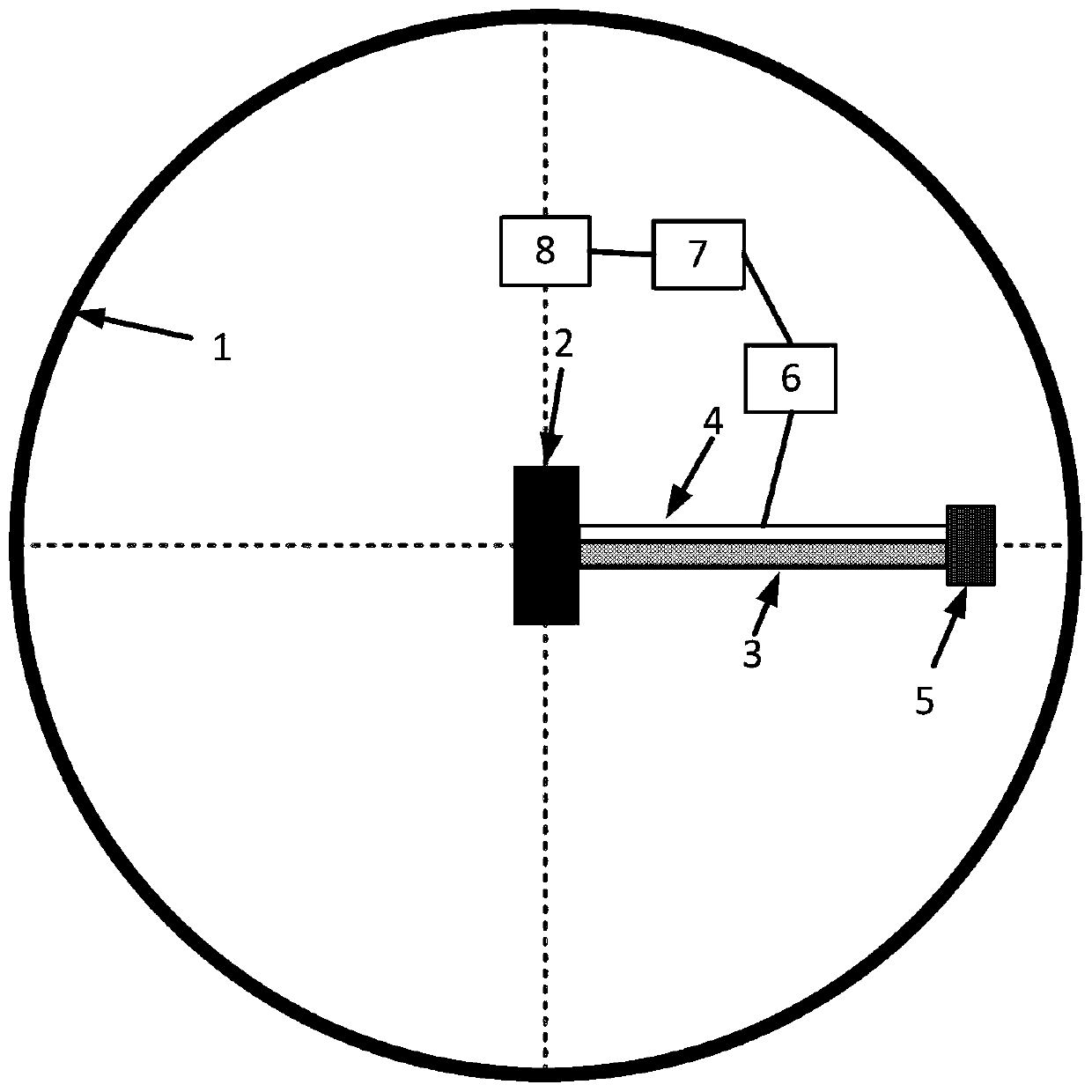

[0034] figure 1 It is a schematic diagram of a rotating machinery broadband piezoelectric energy harvesting mechanism provided by an embodiment of the present invention; figure 1 As shown, the rotating machinery broadband piezoelectric energy harvesting method provided in this embodiment is based on the following energy harvesting mechanism:

[0035] The device of the broadband piezoelectric energy harvesting method for rotating machinery includes: rotating machinery 1, base 2, cantilever beam 3, piezoelectric sheet 4, mass block 5, energy harvesting circuit 6, electric energy storage device 7 and sensor 8; wherein, the rotating machinery 1 rotates around the center; the base 2 is fixed at the center of the rotating machine 1; the cantilever beam 3 is made of non-ferromagnetic metal, one end is connected to the base 2 as a fixed end, and the other end is a free end; the piezoelectric sheet 4 Paste on the cantilever beam 3; the quality block 5 is arranged at the free end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com