Handhold type mineral pneumatic belt type saw

A hand-held, mine-used technology, applied in the direction of sawing machine devices, metal sawing equipment, sawing machine accessories, etc., can solve problems such as hidden safety hazards, out-of-sync, hidden safety hazards, etc., to achieve the elimination of hidden safety hazards, simple structure, and convenient The effect of moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A hand-held mine pneumatic band saw of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

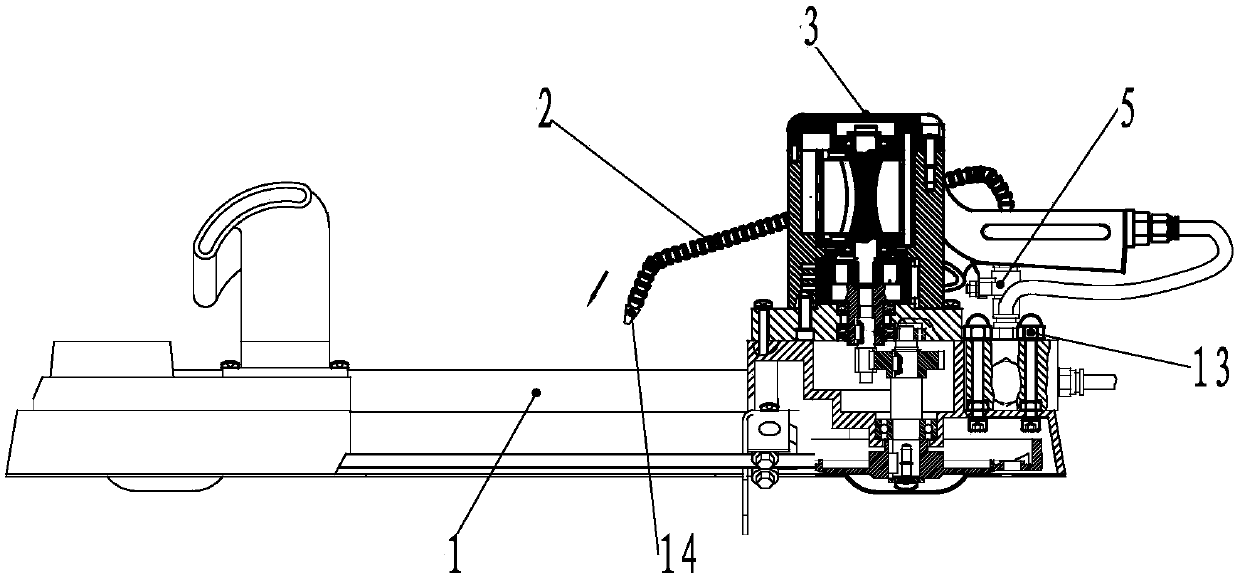

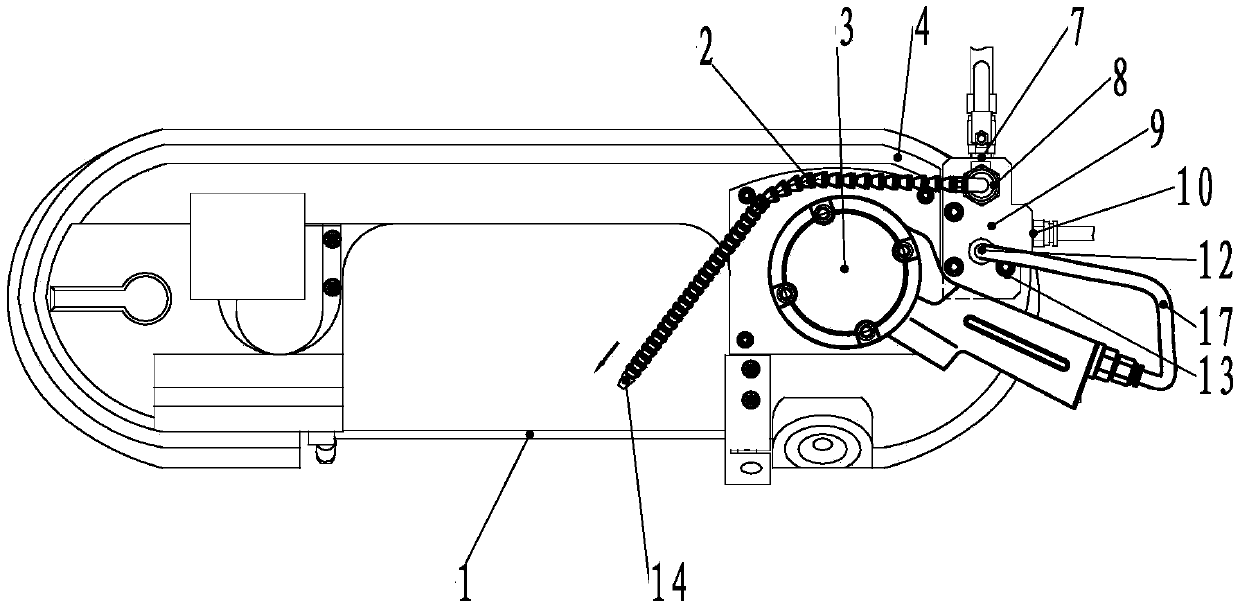

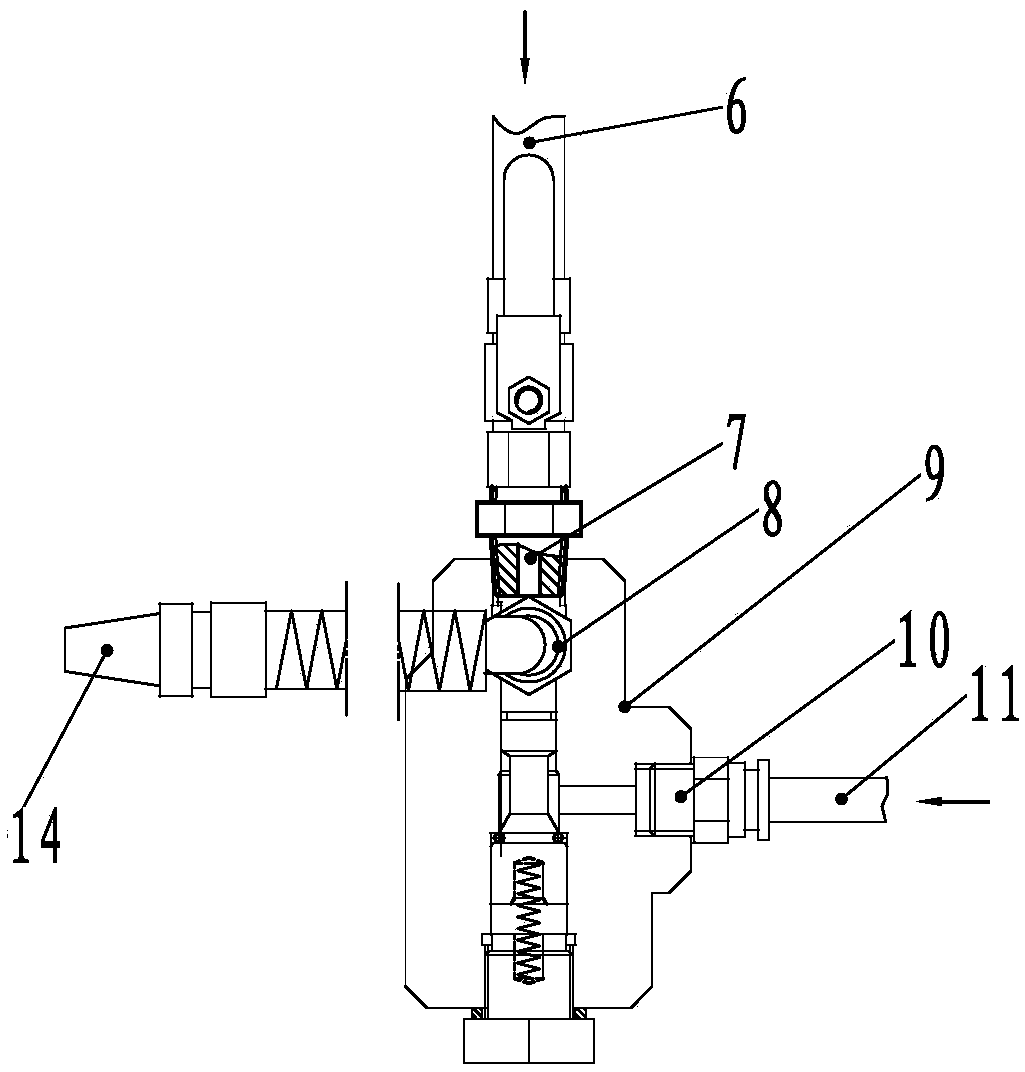

[0017] figure 1 It is a structural schematic diagram of a hand-held mine pneumatic band saw according to the present invention, figure 2 yes figure 1 top view of image 3 It is a schematic diagram of the structure of the gas-water linkage water cut-off protector and the spray pipe. Figure 4 yes image 3 left view of . In the figure, the pneumatic band saw includes a chain 1 driven by an air motor 3, a casing 4 and an air-water linkage water cut-off protector 9, and also includes a water inlet 7, a water outlet 15, and an air-water linkage water cut-off protector 9. The port 10 and the air outlet 12, the air-water linkage water cut-off protector 9 is set on the casing 4, the air-water linkage water cut-off protector 9 is fixed to the casing 4 by screws 13, and the spray pipe 2 is set on the side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com