An environmentally friendly and anti-aging filter gasket and preparation method thereof

A sealing gasket and anti-aging technology, which is applied in the field of environmental protection and anti-aging filter gasket and its preparation, can solve the problems of poor oil resistance of the filter gasket, difficulty in guaranteeing service life, harmfulness of the filter gasket, etc. , achieve good oil resistance, prevent oil corrosion and improve extrusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A kind of preparation method of environmental protection and anti-aging filter gasket, the concrete steps of this method are as follows:

[0034] A. Preparation of base layer 1: Chop nitrile rubber and fluororubber into granules respectively, then put them into a rubber mixer, and start kneading at a temperature of 110-130°C for 5-7min, mix rock wool fiber, butadiene Rosin olefinic acid ester, triethylene glycol diisocaprylate and polyethylene oxide are added to the stirred reactor for stirring, the stirring speed is 800-1000r / min, and the stirring is continued for 20min to prepare a mixed solution, and then to the rubber mixing Add nano-zinc oxide, stearic acid and hydrogen silicone oil into the machine, vacuumize and raise the temperature to 170-180°C and start kneading for 1-1.5 hours, then add the mixed solution and stir evenly to obtain a rubber mixture, which is placed in In a ventilated environment at room temperature for 10-15 hours, add sulfur and paraffin oil,...

Embodiment 2

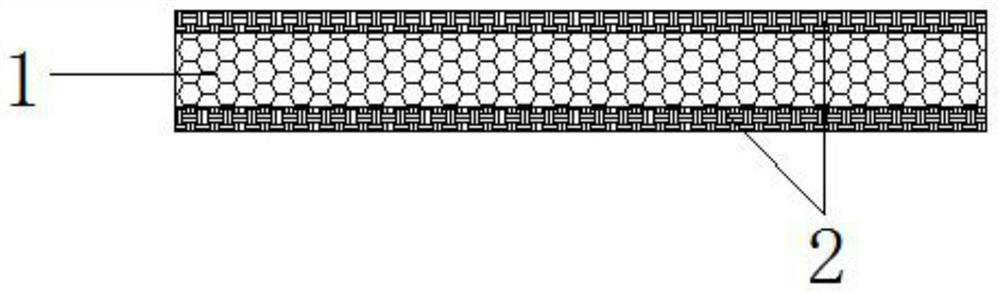

[0047] An environment-friendly and anti-aging filter gasket comprises a base layer 1, and an environment-friendly and anti-aging layer 2 is arranged on the top and bottom of the base layer 1.

[0048] The base layer 1 is prepared from the following raw materials in parts by weight: 45 parts of nitrile rubber, 32 parts of fluororubber, 16 parts of rock wool fiber, 7 parts of rosin maleate, 3.5 parts of triethylene glycol diisocaprylate, 1.5 parts of polyethylene oxide, 4 parts of nano zinc oxide, 4 parts of stearic acid, 2 parts of sulfur, 3 parts of paraffin oil, 1.5 parts of hydrogen silicone oil.

[0049] The environmental protection anti-aging layer 2 is prepared from the following raw materials in parts by weight: 35 parts of nitrile rubber, 23 parts of chlorohydrin rubber, 57 parts of polytetrafluoroethylene powder, 45 parts of rosin maleate, superfine polyimide 4.5 parts of amine resin powder, 3.5 parts of titanium dioxide, 2.5 parts of pigment carbon black, 2.5 parts of...

Embodiment 3

[0051] An environment-friendly and anti-aging filter gasket comprises a base layer 1, and an environment-friendly and anti-aging layer 2 is arranged on the top and bottom of the base layer 1.

[0052] The base layer 1 is prepared from the following raw materials in parts by weight: 50 parts of nitrile rubber, 35 parts of fluororubber, 18 parts of rock wool fiber, 8 parts of rosin maleate, 4 parts of triethylene glycol diisocaprylate, 2 parts of polyethylene oxide, 5 parts of nano zinc oxide, 5 parts of stearic acid, 3 parts of sulfur, 4 parts of paraffin oil, 2 parts of hydrogen silicone oil.

[0053] The environmental protection anti-aging layer 2 is prepared from the following raw materials in parts by weight: 40 parts of nitrile rubber, 25 parts of chlorohydrin rubber, 6 parts of polytetrafluoroethylene powder, 6 parts of rosin maleate, ultrafine polyimide 5 parts of amine resin powder, 5 parts of titanium dioxide, 3 parts of pigment carbon black, 5 parts of essence, 1 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com