Portable container capable of being repeatedly filled with compressed gas

A compressed gas, portable technology, applied in the directions of closing, packaging, transportation and packaging, can solve the problem that the oxygen cylinder cannot be reused, and achieve the effect of being conducive to multiple filling and use, reducing costs and improving utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

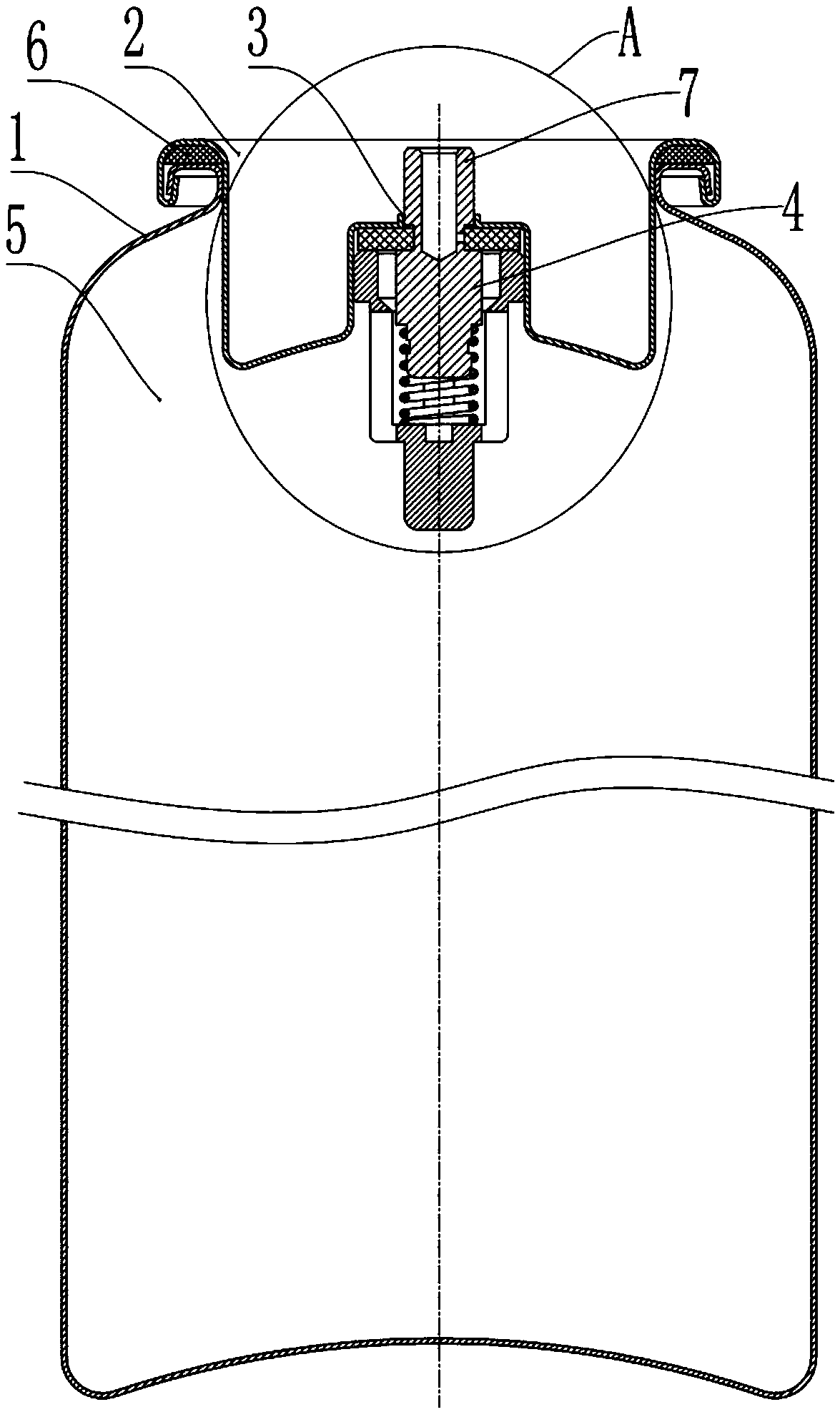

[0034] combine figure 1 and figure 2 , a portable container that can be repeatedly filled with compressed gas, including a bottle body 1 and a bottle cap 2 made of aluminum alloy. The two-way valve 4, the bottle cap 2, the bottle body 1 and the two-way valve 4 form a closed cavity 5; A sealing gasket 6 is provided at the fastening position; the bottle cap 2 is recessed into the bottle body 1; and the two-way valve 4 is located in the bottle body 1 .

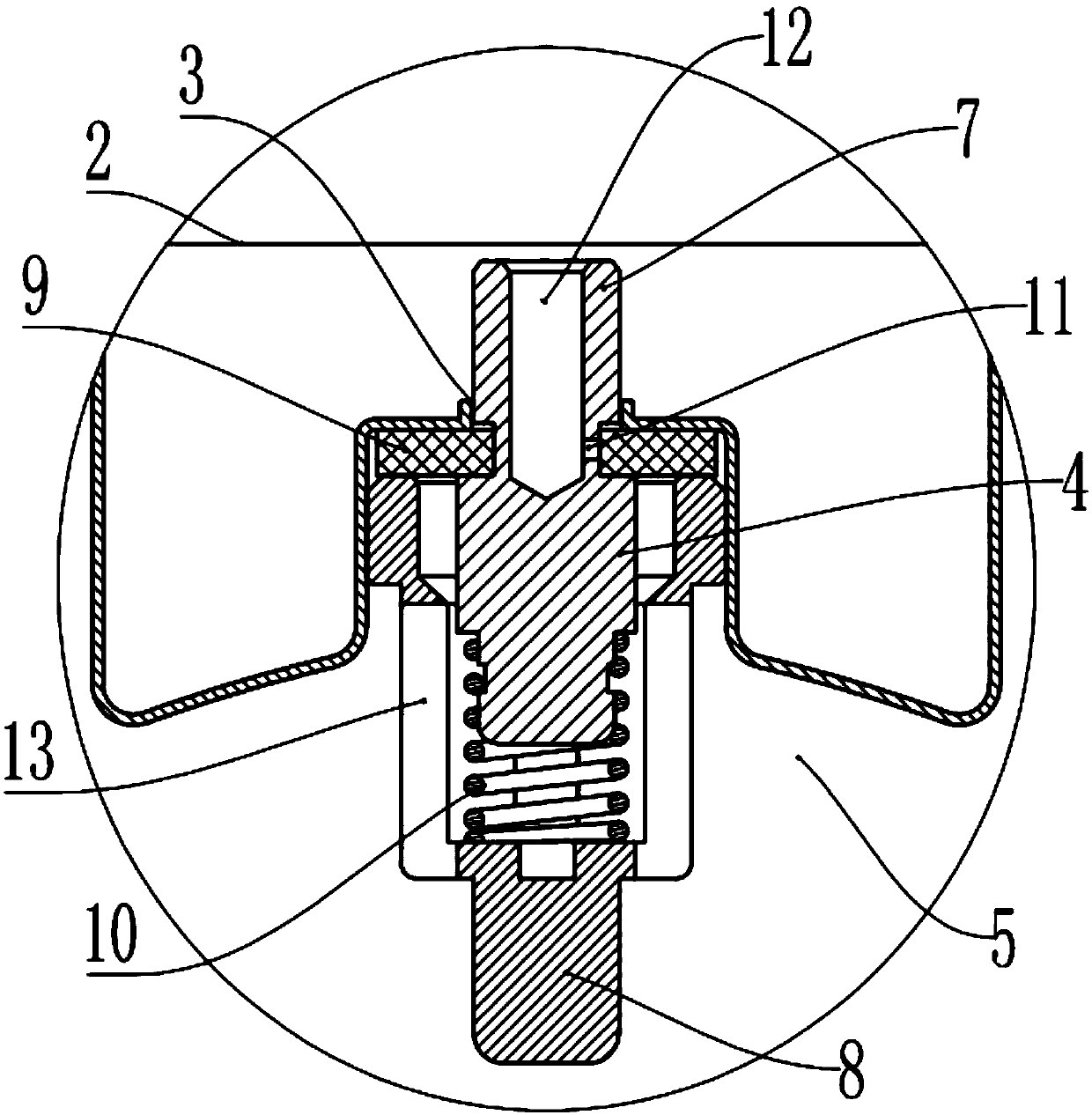

[0035] combine figure 2 The two-way valve 4 includes a valve core 7, a valve seat 8, an oil seal 9 and a spring 10. The valve core 7 is slidably connected to the communication hole 3 of the bottle cap 2, and the valve seat 8 and the bottle cap 2 are fixed by interference fit and bonding. Connection, the valve seat 8 is located in the space enclosed by the bottle cap 2 and the bottle body 1, the valve seat 8 and the valve core 7 are connected by a spring 10, the oil seal 9 is located between the valve seat 8 and the bottle ca...

Embodiment 2

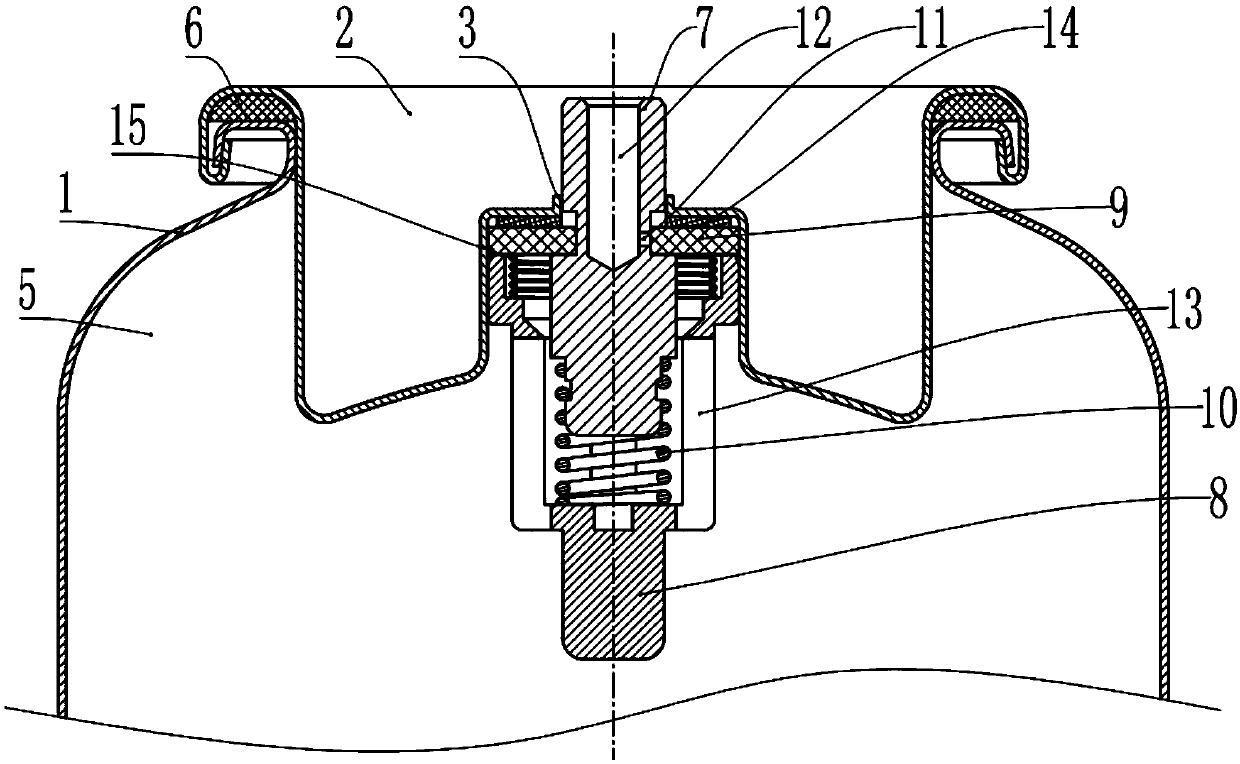

[0046] Example two such as image 3 As shown, Embodiment 2 changes the two-way valve 4 on the basis of Embodiment 1, and reduces the contact area between the valve seat 8 and the oil seal 9 on the valve seat 8, that is, the material on the valve seat 8 is partially removed and processed as image 3 As shown in the step, the compression spring 15 is installed on the step, and the compression spring 15 and the valve seat 8 are used to offset the oil seal 9. At the same time, a sealing ring 14 is set between the oil seal 9 and the bottle cap 2, and the sealing ring 14 is sleeved on the valve core. 7, the sealing ring 14 does not move or deform when the valve core 7 moves up and down.

[0047] Reduce the contact area between the valve seat 8 and the oil seal 9, and use the compression spring 15 to replace the material removal part of the valve seat 8. When the oil seal 9 is deformed by the downward movement of the valve core 7, the oil seal 9 will drive the compression spring 15 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com