Farming wastewater anaerobic treatment process

A technology for anaerobic treatment of aquaculture sewage, applied in the field of anaerobic treatment of aquaculture sewage, can solve the problems of three-phase separator blockage, paralysis, and high load of the back-end biochemical system, achieve short running time, reduce the concentration of suspended solids, and ensure The effect of biogas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

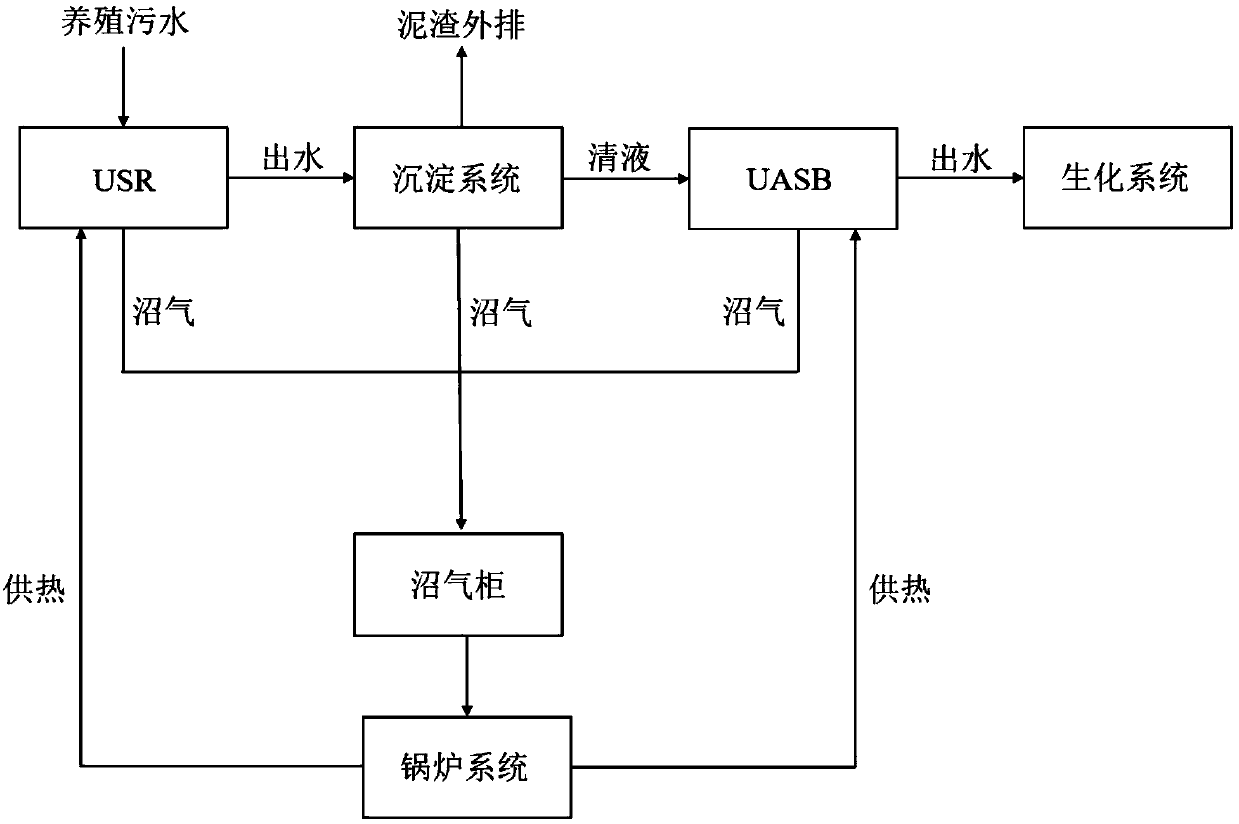

[0029] A kind of aquaculture sewage anaerobic treatment process (process flow chart sees figure 1 ), including the following steps (ambient temperature: 5-10°C):

[0030] 1) Install a three-phase separator in the USR, optimize the water distribution system of the USR, and then pass the aquaculture sewage (organic pollutant concentration: COD = 20000mg / L) into the USR (hydraulic retention time: 5 days, and maintain the internal temperature at 33 ~38℃), anaerobic treatment is carried out, and the generated biogas is passed into the biogas tank;

[0031] 2) Pass the effluent of USR into the sedimentation system for 3 hours of natural precipitation, the generated sludge is discharged, and the generated biogas is passed into the biogas tank;

[0032] 3) Pass the clear liquid in the sedimentation system (organic pollutant concentration: COD=9000mg / L) into UASB (hydraulic retention time: 3 days, internal temperature maintained at 23-28°C) for anaerobic treatment, and the generated b...

Embodiment 2

[0036] A kind of aquaculture sewage anaerobic treatment process (process flow chart sees figure 1 ), including the following steps (ambient temperature: 5-10°C):

[0037] 1) Install a three-phase separator in the USR, optimize the water distribution system of the USR, and then pass the aquaculture sewage (organic pollutant concentration: COD = 20000mg / L) into the USR (hydraulic retention time: 7 days, and maintain the internal temperature at 33 ~38℃), anaerobic treatment is carried out, and the generated biogas is passed into the biogas tank;

[0038] 2) Pass the effluent of USR into the sedimentation system for 4 hours of natural precipitation, the generated sludge is discharged, and the generated biogas is passed into the biogas tank;

[0039] 3) Pass the clear liquid in the sedimentation system (organic pollutant concentration: COD=8000mg / L) into the UASB (hydraulic retention time: 3 days, internal temperature maintained at 23-28°C) for anaerobic treatment, and the generat...

Embodiment 3

[0043] A kind of aquaculture sewage anaerobic treatment process (process flow chart sees figure 1 ), including the following steps (ambient temperature: 5-10°C):

[0044] 1) Install a three-phase separator in the USR, optimize the water distribution system of the USR, and then pass the aquaculture sewage (organic pollutant concentration: COD = 20000mg / L) into the USR (hydraulic retention time: 10 days, and maintain the internal temperature at 33 ~38℃), anaerobic treatment is carried out, and the generated biogas is passed into the biogas tank;

[0045] 2) Pass the effluent of USR into the sedimentation system for 6 hours of natural precipitation, the generated sludge is discharged, and the generated biogas is passed into the biogas tank;

[0046] 3) Pass the clear liquid in the sedimentation system (organic pollutant concentration: COD=6800mg / L) into the UASB (hydraulic retention time: 5 days, internal temperature maintained at 23-28°C) for anaerobic treatment, and the genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com