Hard polyurethane composite polyether for high-strength refrigerated compartment

A technology of rigid polyurethane and combined polyether, which is applied in the field of polyurethane combined polyether, can solve problems such as economic loss, affecting the service life of the refrigerated compartment, and damage to the refrigerated compartment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

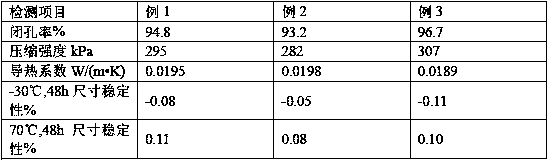

Examples

Embodiment Construction

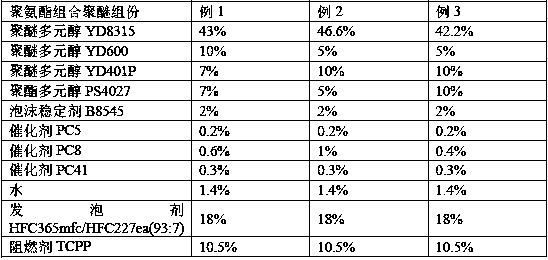

[0019] A high-strength refrigerated compartment rigid polyurethane combination polyether, composed of A component and B component, the weight ratio of the two is 1:1.2-1.5, B component is polymethylene polyphenylisocyanate, A component Including the following raw materials in weight percentage: polyether polyol I is 35-45%, polyether polyol II is 5-15%, polyether polyol III is 5-10%, polyester polyol I is 5-15% , the foam stabilizer is 1.5-2.5%, the catalyst is 0.5-2%, the water is 1.0-2.5%, the foaming agent is 5-25%, and the flame retardant is 10-15%; among them:

[0020] Polyether polyol I is a polyether polyol with a functionality of 4-7, a number average molecular weight of 500-800, a hydroxyl value of 435-465mgKOH / g, and a viscosity of 16000-19000mPa.s at 25°C; polyether polyol Alcohol II is a sorbitol polyether polyol with a functionality of 4-6, a number average molecular weight of 500-700, a hydroxyl value of 440-470mgKOH / g, and a viscosity of 13000-17000mPa.s at 25°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com