A slidable support structure suitable for liquid natural gas pipelines

A technology of liquefied natural gas and support structure, which is applied in the direction of pipeline supports, pipes/pipe joints/pipe fittings, mechanical equipment, etc., which can solve the problems of inconvenient adjustment of pipeline support height, affecting the axial shrinkage and sliding of pipelines, and difficult to observe, etc., to achieve Axial contraction and sliding are convenient and reliable, avoiding excessive or too fast descent, and conducive to the effect of stable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

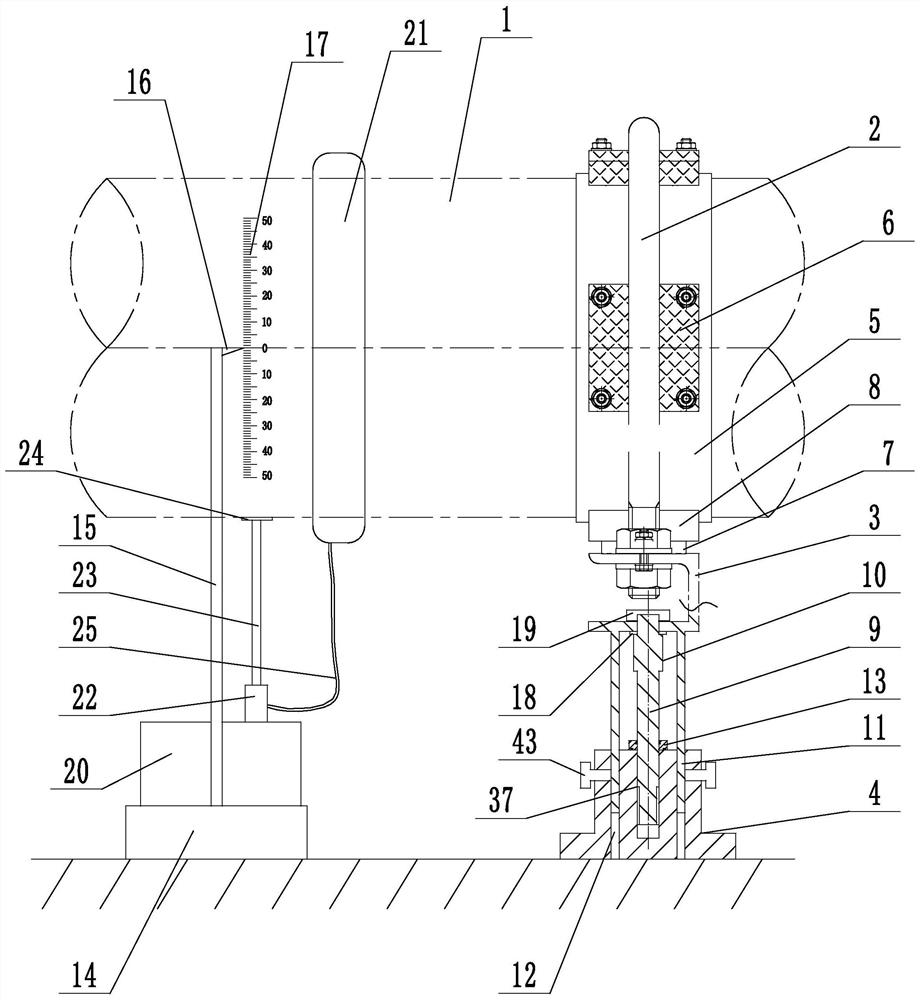

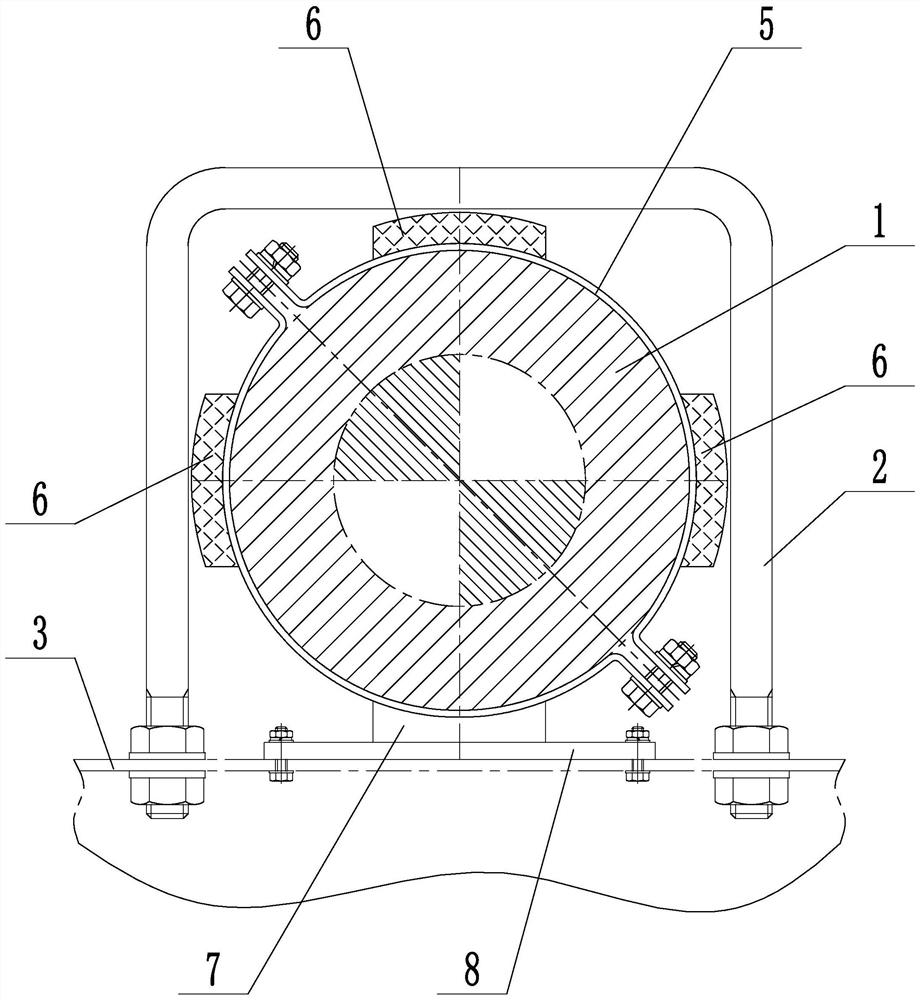

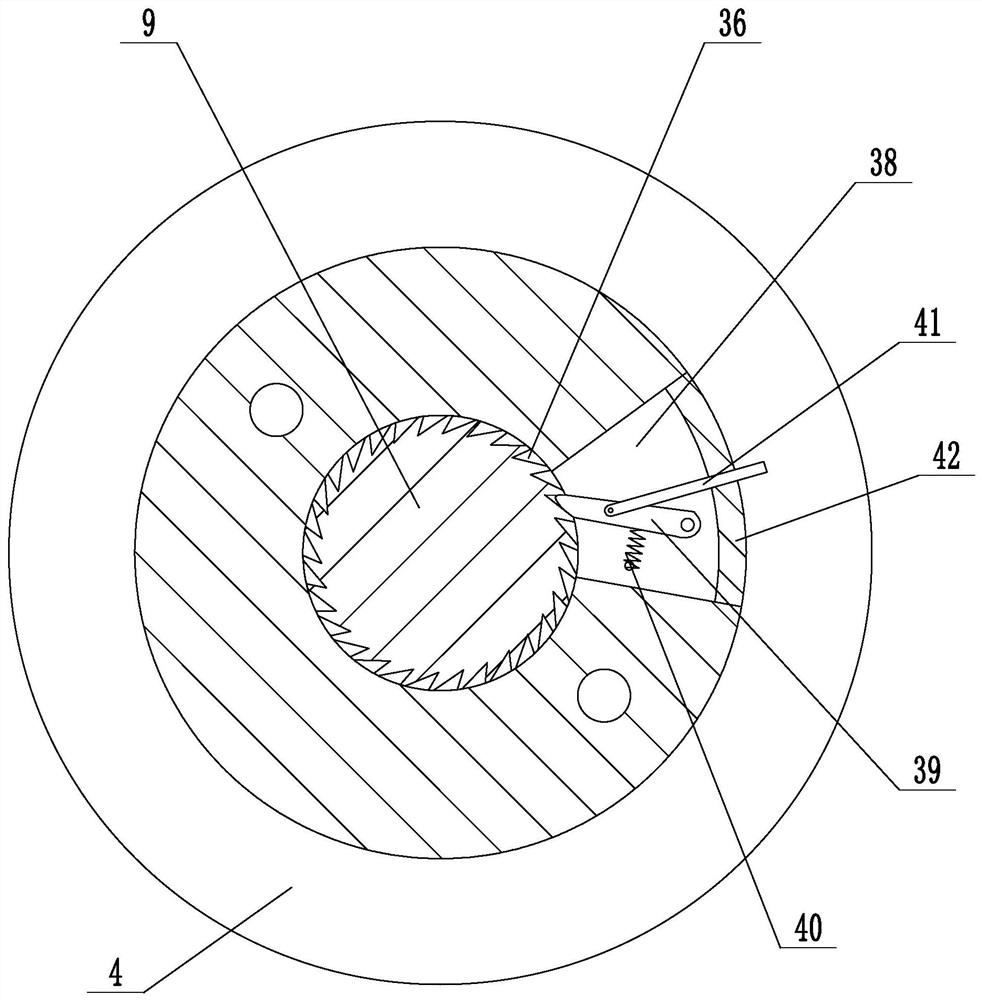

[0024] Example: A slidable support structure suitable for liquid natural gas pipelines (see attached figure 1 Attached Figure 4 ), including the liquid natural gas pipeline 1, the positioning frame 2, the support seat 3, and the base 4 fastened to the hull. The positioning frame is in an inverted U-shaped structure and is covered on the liquid natural gas pipeline, and both ends of the opening of the positioning frame are tightly connected On the support seat, the support seat is connected with the base, the outer wall of the liquid natural gas pipeline and the corresponding position of the positioning frame are connected to the hoop 5, and the left side wall, the right side wall and the upper side wall of the hoop are installed with curved sliding pads 6 , The support block 7 is installed on the lower side wall of the hoop, the sliding pad is placed between the hoop and the positioning frame, the sliding pads are all attached to the positioning frame, the support seat is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com