Detection device for heat stimulation current method

A technology of thermal stimulation current and detection device, which is applied in the direction of measuring device, measuring heat, and optical testing for flaws/defects, etc. It can solve the problems of sample breakdown, test data jump, inability to approach the sample to detect sample temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

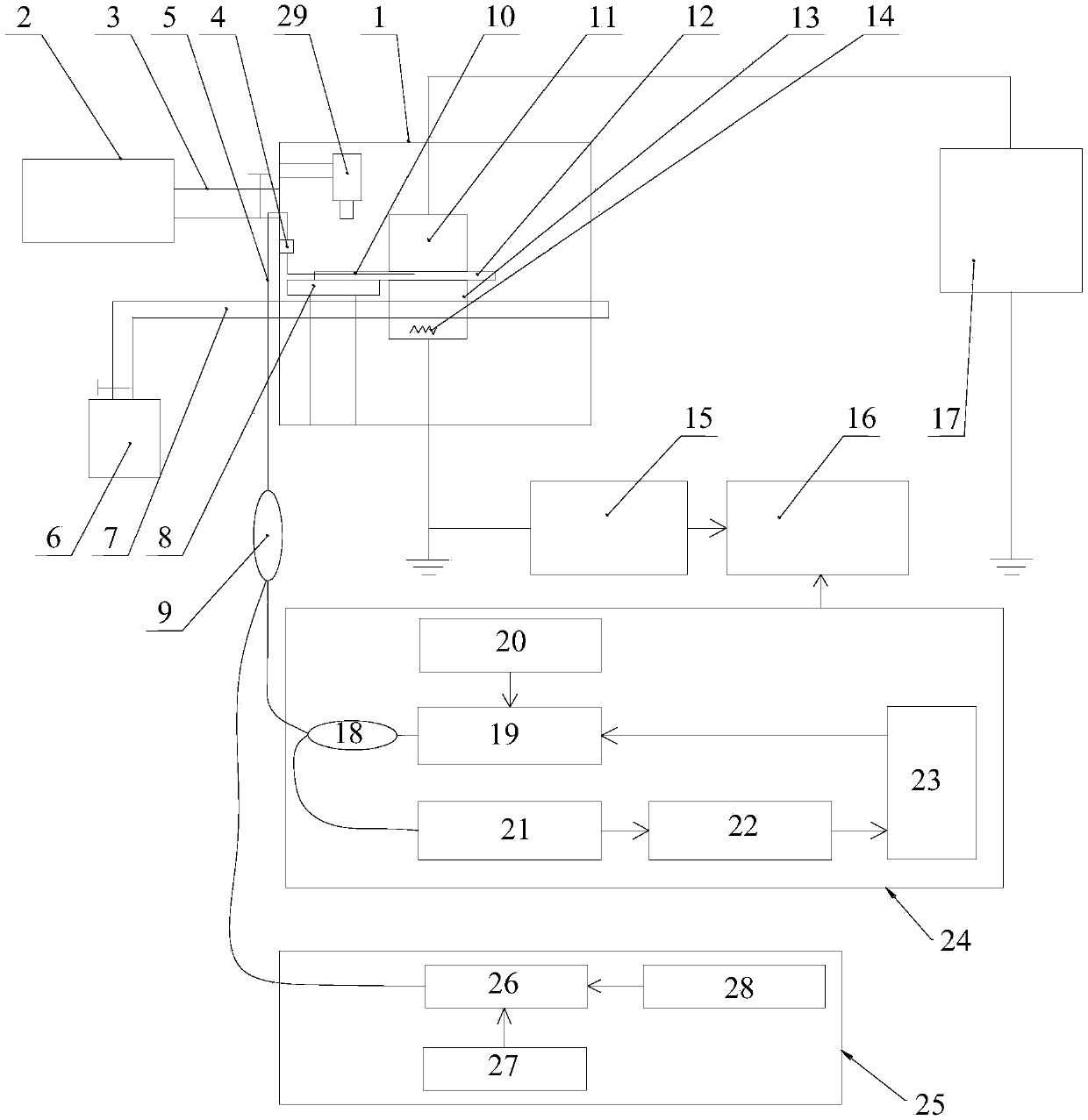

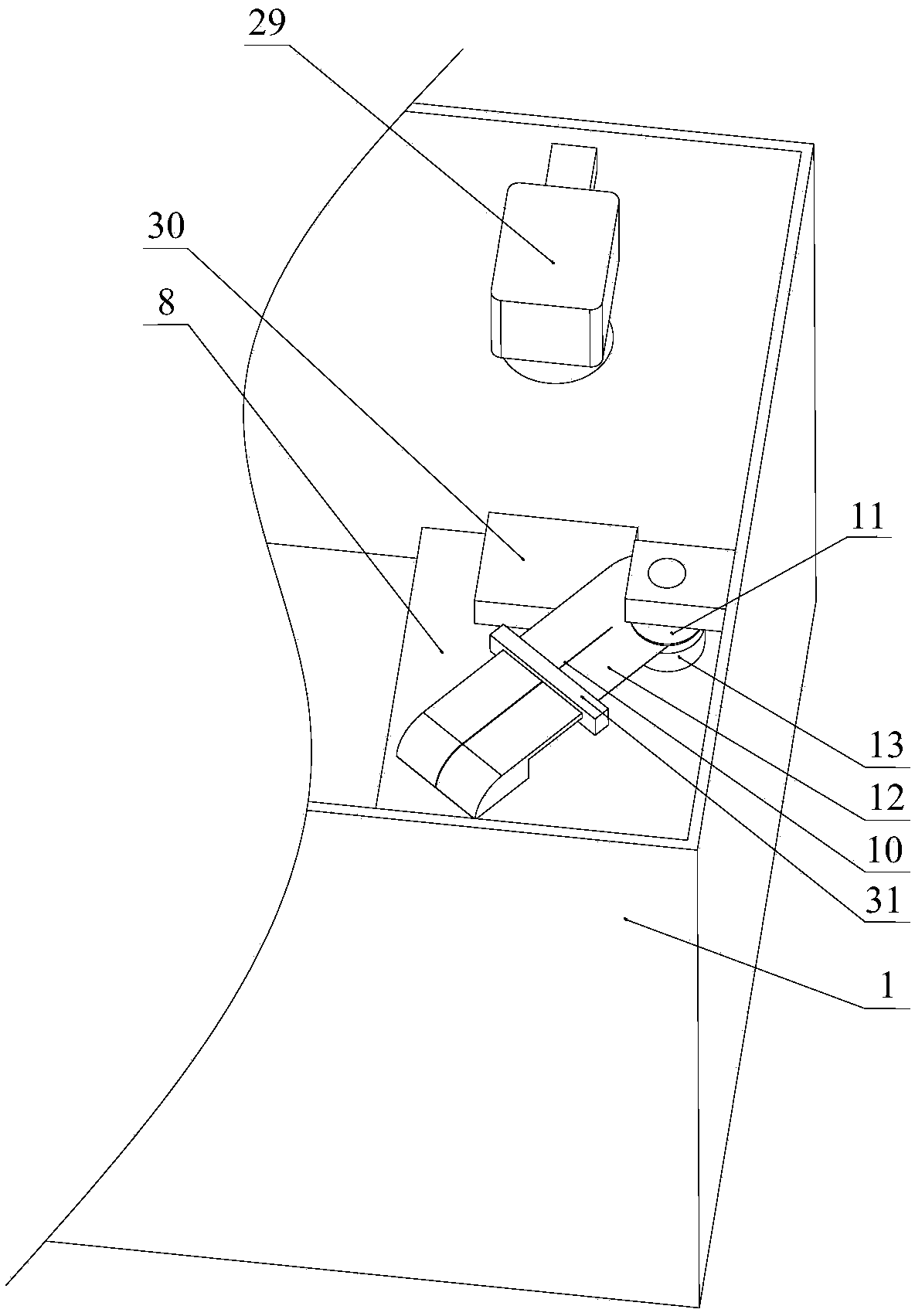

[0041] Below in conjunction with each accompanying drawing, the present invention is described in detail.

[0042] like figure 1 , 2Shown in and 3, a kind of detection device that is used for thermal stimulation electric current method comprises vacuum chamber 1; Vacuum pump 2 is connected with vacuum chamber 1, is used for vacuumizing vacuum chamber 1; The lower electrode 13 is arranged in the vacuum chamber 1 and is located directly below the upper electrode 11, and the sample space is between the lower electrode 13 and the upper electrode 11; the heating wire 14 is arranged in the lower electrode 13 for heating the lower electrode 13 ; The cooling mechanism is used to cool the lower electrode 13, and also includes:

[0043] The optical fiber connector 4 is fixed on the inner wall of the vacuum chamber 1;

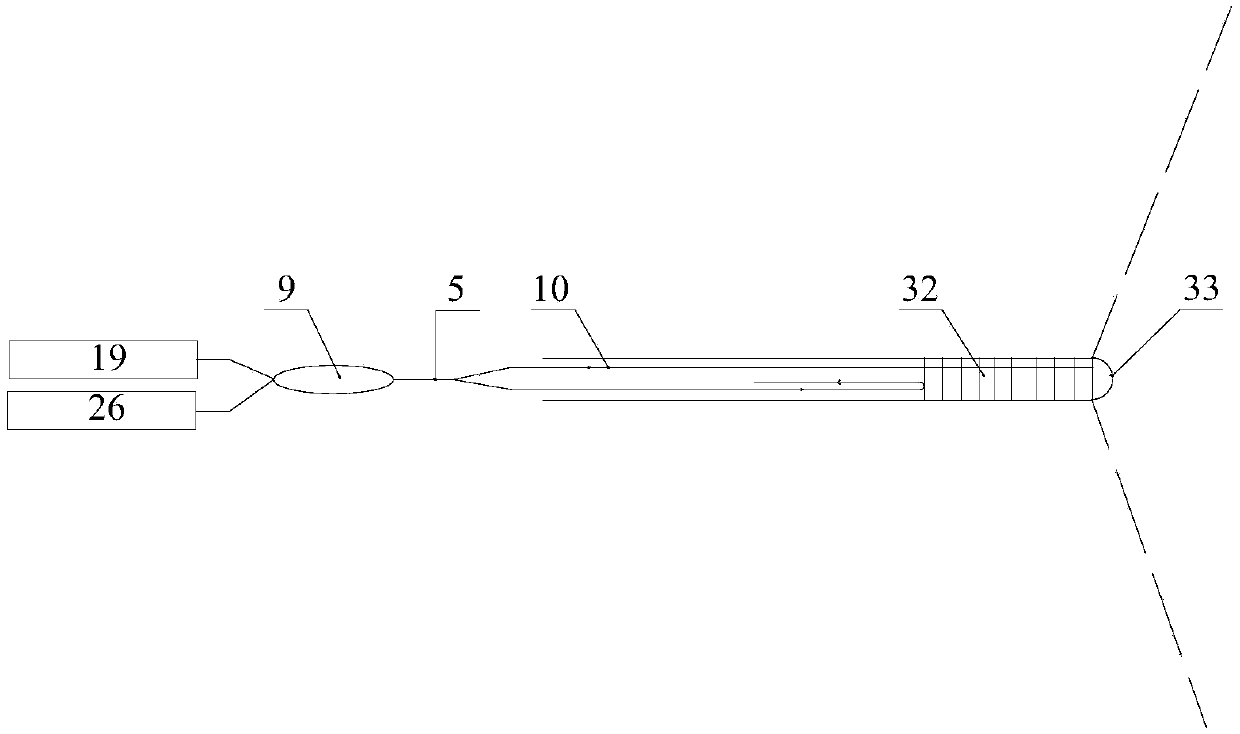

[0044] Transmission optical fiber 5, one end is connected with the optical fiber connector 4, and the other end passes through the vacuum chamber 1 for connecting with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com