Optic fiber temperature pressure sensor and probe thereof

A pressure sensor, optical fiber temperature technology, used in measurement, wellbore/well components, earthmoving, etc., can solve problems such as lower yield, failure, and large differences in thermal expansion coefficients, to avoid damage or leakage, and ensure sealing. The effect of high performance and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

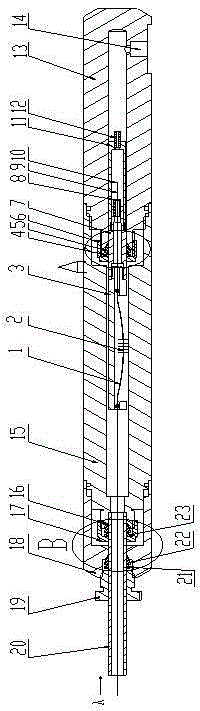

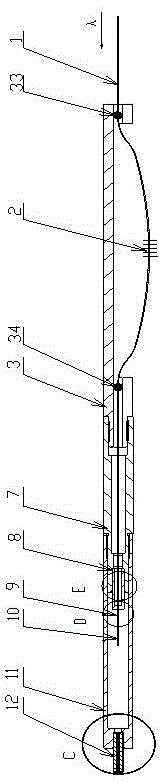

[0028] Such as figure 1 and 2 Shown, a kind of optical fiber temperature pressure sensor probe, it comprises intermediate sleeve 15, outer layer sleeve 18, connecting pipe 20, main body protection sleeve 13 and the main body sleeve 7 that is fixedly arranged at one end of main body protection sleeve 13, in The two ends of the main body sleeve 7 are respectively fixedly provided with an optical fiber Fabry-Perot cavity protection sleeve 11 and a fiber grating protection member 3, and the optical fiber Fabry-Perot cavity protection sleeve 11 is inserted into the main body protection sleeve 13; A quartz glass pressure inlet tube 12 is fixedly arranged on the end of the Fabry Perot cavity protection sleeve 11 opposite to the main body sleeve 7 .

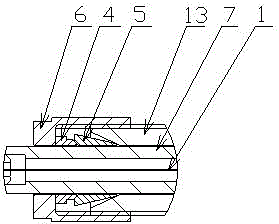

[0029] Such as Figure 7 and 8 As shown, a ferrule 8 is fixedly arranged in the main body sleeve 7, and a quartz glass capillary 9 and a first optical fiber segment 1 and a second optical fiber segment 10 inserted and fixed from both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com