Marinating material and preparation method thereof

A technology of brine and auxiliary materials, which is applied in the field of brine and its preparation, can solve the problems of short shelf life, harm to the body of the eater, perishable deterioration, etc., and achieve the effects of low production cost, convenient operation, and enhanced anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

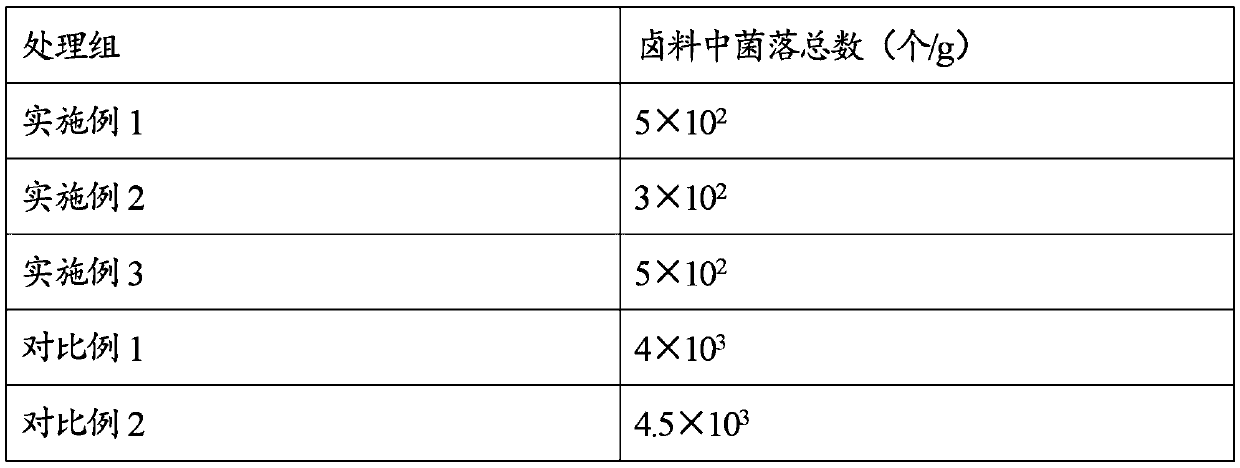

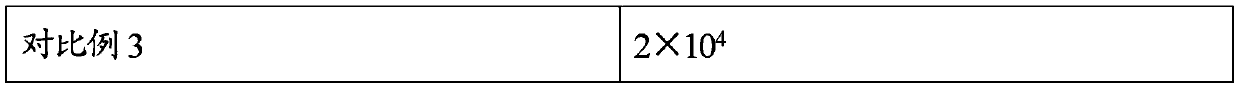

Examples

Embodiment 1

[0021] A kind of halogen material, described preparation method comprises the following steps:

[0022] (1) Star anise, cassia bark, fennel, dried chili, bay leaves, cloves, and ginkgo leaves are mixed according to the weight ratio and placed in a pulverizer to be pulverized into powder, so as to obtain the pulverized primary mixture;

[0023] (2) Frying the pulverized primary mixture for six matures to obtain six mature primary mixtures;

[0024] (3) Put the auxiliary materials in the oil pan and fry them until they are cooked and put them in the container to obtain the fried auxiliary materials;

[0025] (4) add pure water in pot by weight ratio, pure water is boiled, obtains boiled pure water;

[0026] (5) Add the fried auxiliary materials to the boiled pure water for 1 hour, then add the six-mature primary mixture and cook for 3 hours;

[0027] (6) Use a filter to filter, and the obtained filtrate is the halogen material, and the filtrate is sealed with a glass jar.

Embodiment 2

[0029] A kind of halogen material, described preparation method comprises the following steps:

[0030] (1) Star anise, cassia bark, fennel, dried chili, bay leaves, cloves, and ginkgo leaves are mixed according to the weight ratio and placed in a pulverizer to be pulverized into powder, so as to obtain the pulverized primary mixture;

[0031] (2) Frying the pulverized primary mixture to obtain seven mature primary mixtures;

[0032] (3) Put the auxiliary materials in the oil pan and fry them until they are cooked and put them in the container to obtain the fried auxiliary materials;

[0033] (4) add pure water in pot by weight ratio, pure water is boiled, obtains boiled pure water;

[0034] (5) Add fried auxiliary materials to boiled pure water for 1 hour, then add seven-ripe primary mixture and cook for 3 hours;

[0035] (6) Use a filter to filter, and the obtained filtrate is the halogen material, and the filtrate is sealed with a glass jar.

Embodiment 3

[0037] A kind of halogen material, described preparation method comprises the following steps:

[0038] (1) Star anise, cassia bark, fennel, dried chili, bay leaves, cloves, and ginkgo leaves are mixed according to the weight ratio and placed in a pulverizer to be pulverized into powder, so as to obtain the pulverized primary mixture;

[0039] (2) Fry the pulverized primary mixture to eight matures to obtain eight mature primary mixtures:

[0040] (3) Put the auxiliary materials in the oil pan and fry them until they are cooked and put them in the container to obtain the fried auxiliary materials;

[0041] (4) add pure water in pot by weight ratio, pure water is boiled, obtains boiled pure water;

[0042] (5) Add the stir-fried auxiliary materials to the boiled pure water for 1 hour, then add the eight-mature primary mixture and cook for 3 hours:

[0043] (6) Use a filter to filter, and the obtained filtrate is the halogen material, and the filtrate is sealed with a glass ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com