Large combined type sand and gravel aggregate screening machine

A combined, screening machine technology, applied in the direction of sieve, solid separation, removal of smoke and dust, etc., can solve the problems of vibrating screen weight, high energy consumption, unbalanced equipment large-scale, large screen spacing, etc., to solve the problem of dust. , convenient classification and subsequent processing, the effect of preventing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

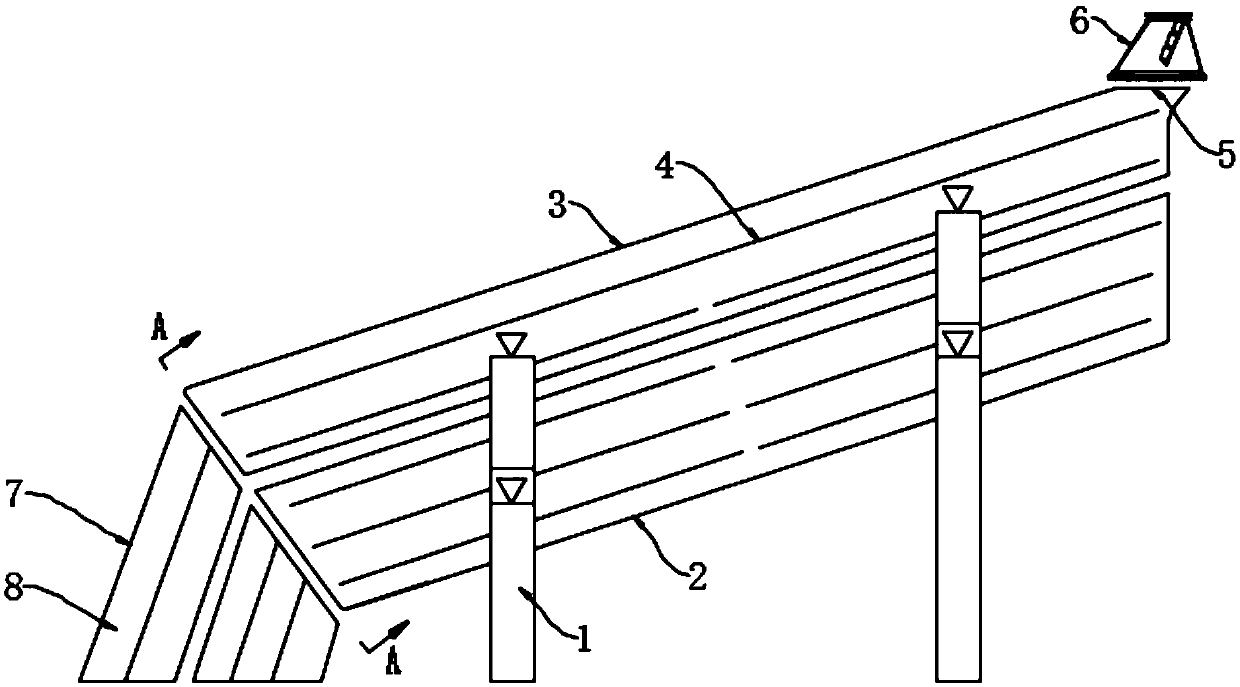

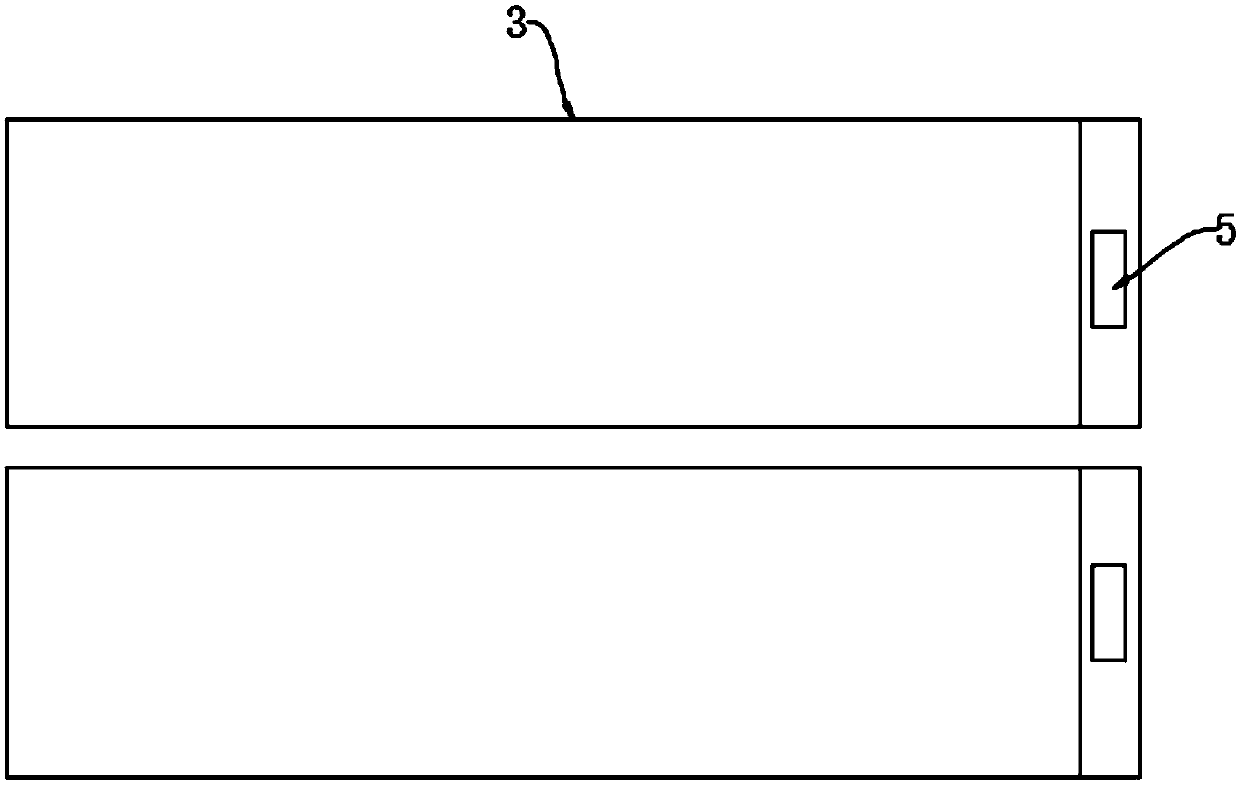

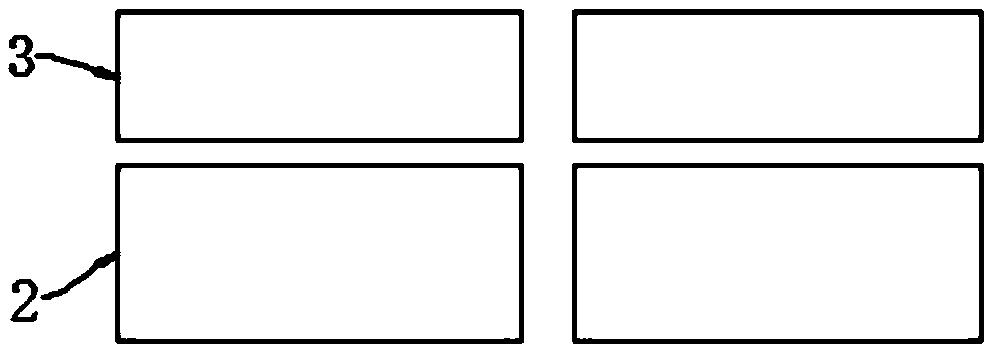

[0025] see Figure 1~3 , in the embodiment of the present invention, a large-scale combined sand and gravel aggregate screening machine includes a sieve body support column 1, a lower sieve body 2 and an upper sieve body 3 are fixedly arranged on the sieve body support column 1, and the lower sieve body 2 and the upper sieve body 3 are cuboid structures, and the lower sieve body 2 and the upper sieve body 3 are all inclined to the lower left; by changing the existing circular vibrating sieve into a linear vibrating sieve, the screening efficiency is improved; the upper sieve The sieve body 3 is located directly above the lower sieve body 2, and the lower sieve body 2 and the upper sieve body 3 are respectively provided with several, and the upper sieve body 3 and the lower sieve body 2 have the same number and one-to-one correspondence. Preferably, the lower sieve body 2 and the upper sieve body 3 are respectively provided with two; the top right side of the upper sieve body 3...

Embodiment 2

[0029] see Figure 4 , on the basis of Embodiment 1, it also includes an outer casing 9, the upper sieve body 3, the lower sieve body 2, and the distributor 7 are all located in the outer casing 9 to prevent dust from flying out; the distributor 6 passes through the outer casing The body 9 extends to the outside of the outer shell 9, which is convenient for feeding; the top of the outer shell 9 is provided with a dust collection port 10, and by connecting a vacuum cleaner at the dust collection port 10, the dust is recovered by the vacuum cleaner, which completely solves the dust raising problem of the vibrating screen , more environmentally friendly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com