Plastic film folding machine

A plastic film and folding machine technology, applied in the direction of folding thin materials, thin material processing, winding strips, etc., can solve the problems of small thickness of plastic films, difficult to fold plastic films, low plasticity, etc. The effect of high efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific technical solutions of the present invention will be further described below in conjunction with the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

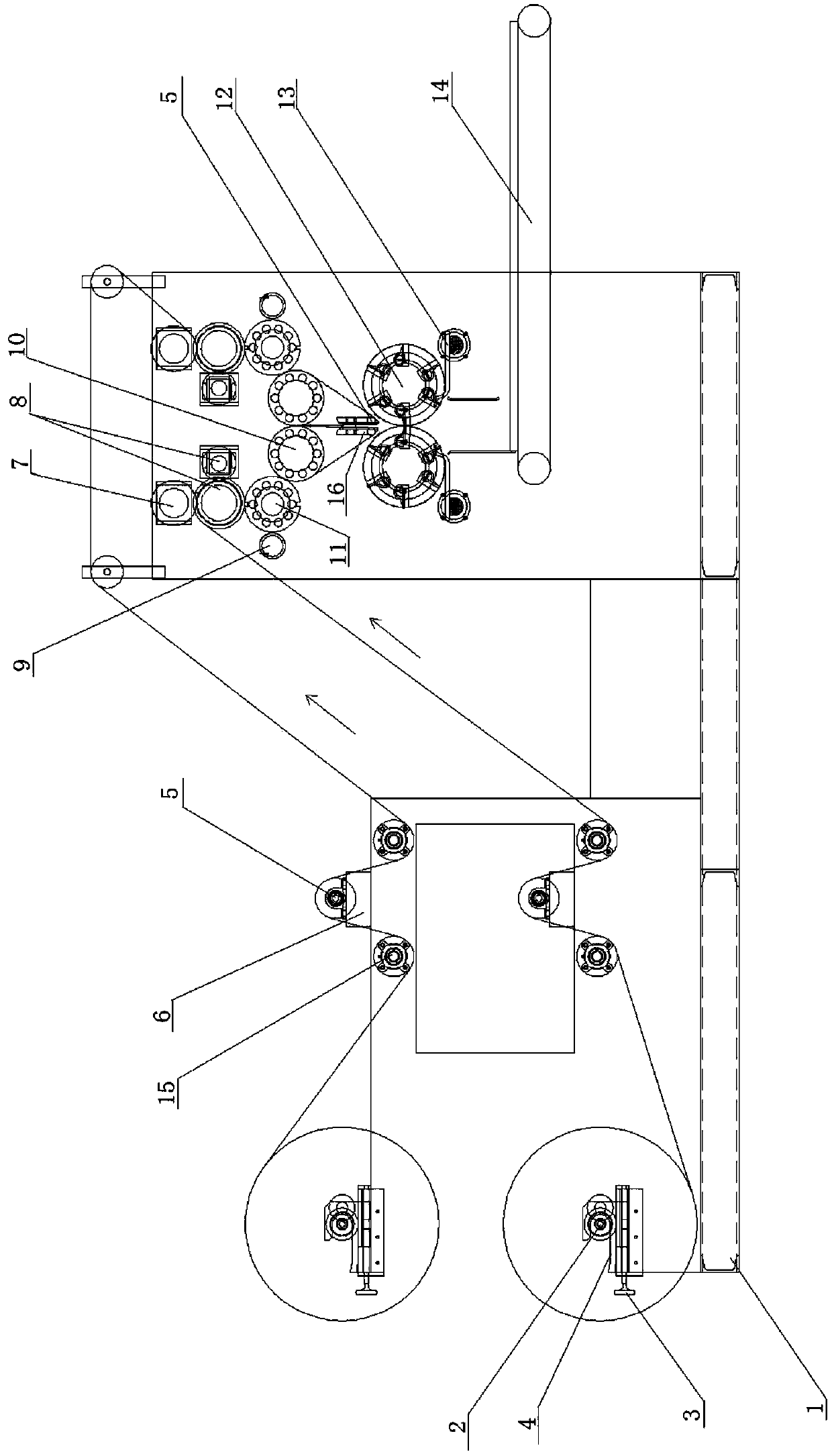

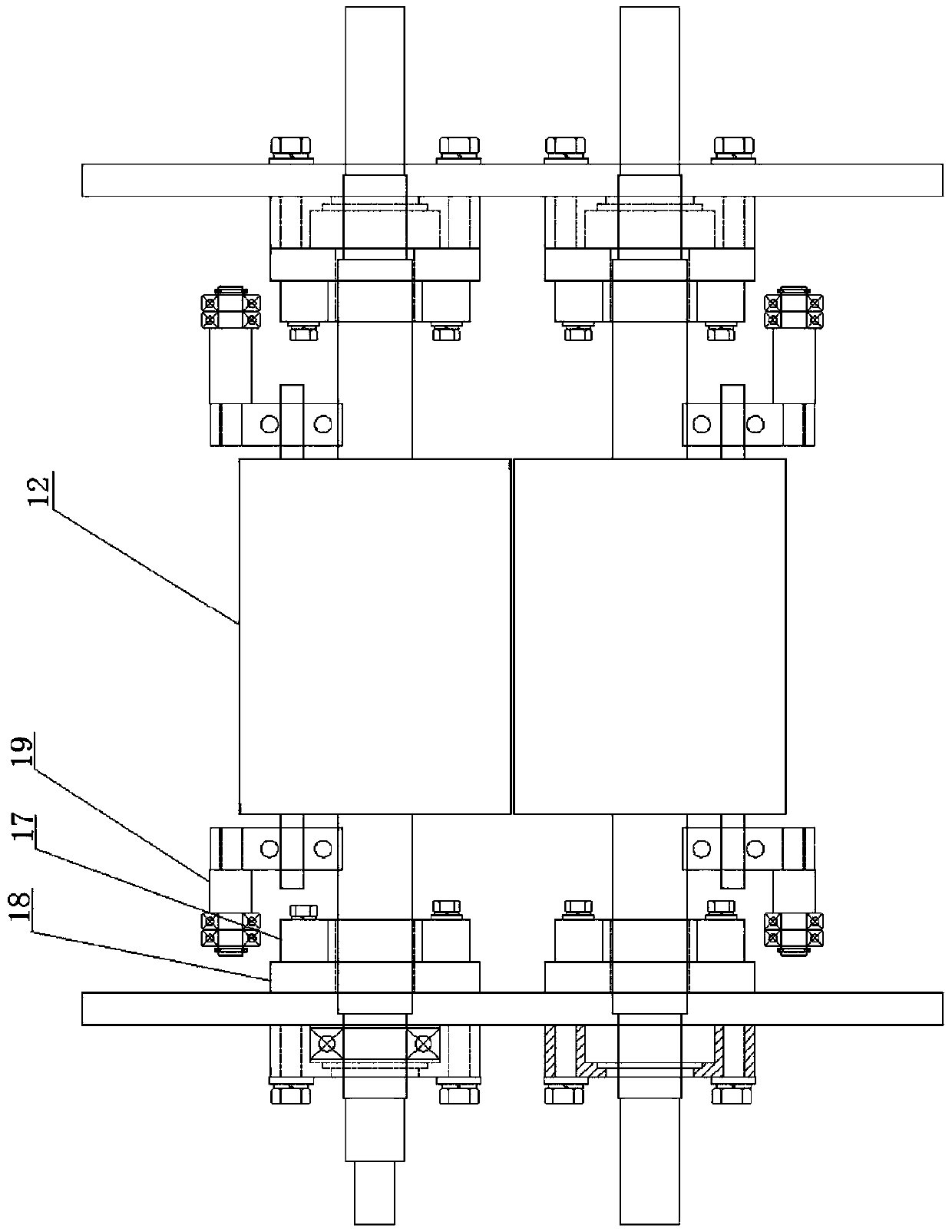

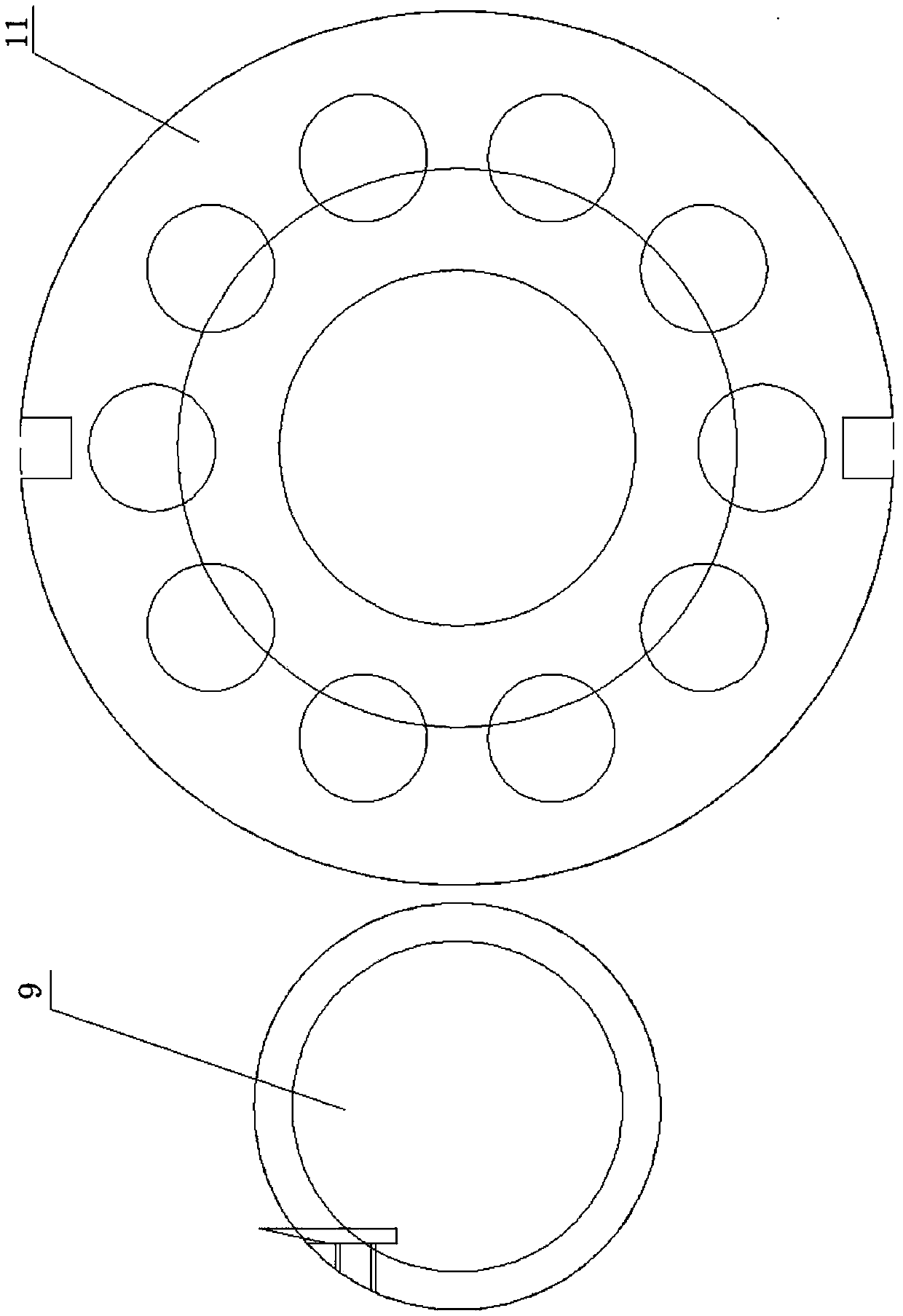

[0022] A plastic film folding machine is provided with an interlocking folding mechanism, and a branching and switching mechanism is arranged on the frame 1 above the interlocking folding mechanism. The interlocking folding mechanism includes two vacuum adsorption folding rollers 12 and two vacuum adsorption reversing rollers I10. The two vacuum adsorption folding rollers 12 are symmetrically arranged side by side. Material channel 16, two vacuum adsorption reversing rollers I10 are symmetrically arranged side by side above the feeding channel 16. Two guide rollers I5 are symmetrically arranged on both sides of the end, and each guide roller I5 is connected with the vacuum adsorption reversing roller I10 on the same side thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com