Blast furnace air supply device straight blowing pipe with temperature alarming and automatic treatment device

A technology of a disposal device and an air supply device, which is applied in the field of direct blowing pipes, can solve problems such as high temperature of direct blowing pipes, casualties, and potential safety hazards, so as to avoid excessive temperature burn-through, avoid low efficiency of manual temperature measurement, and avoid safety hazards. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

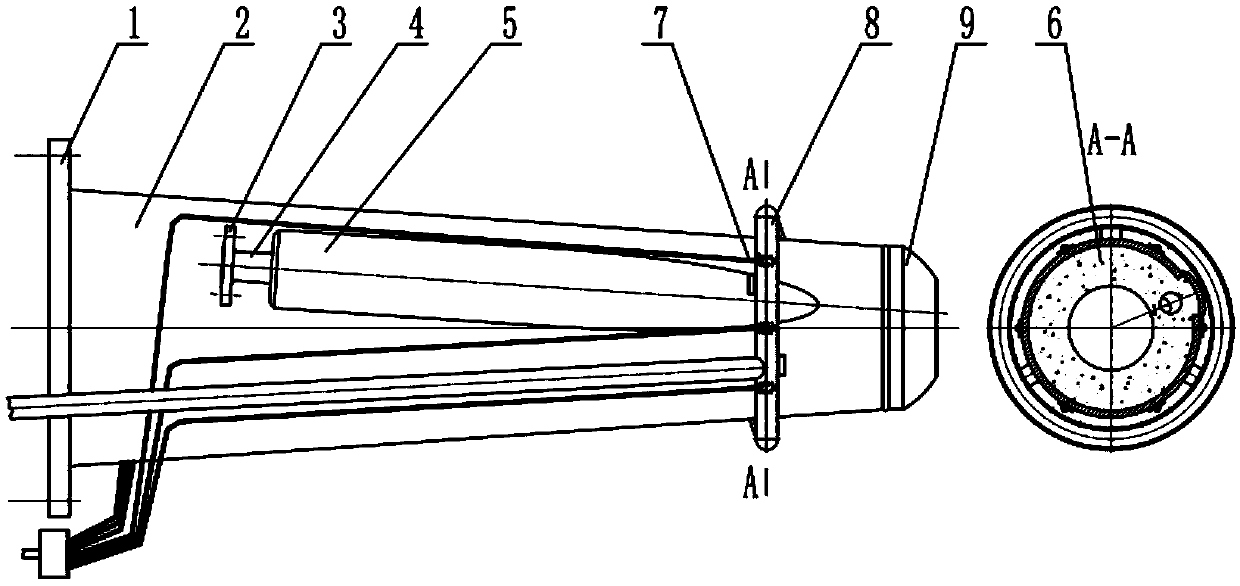

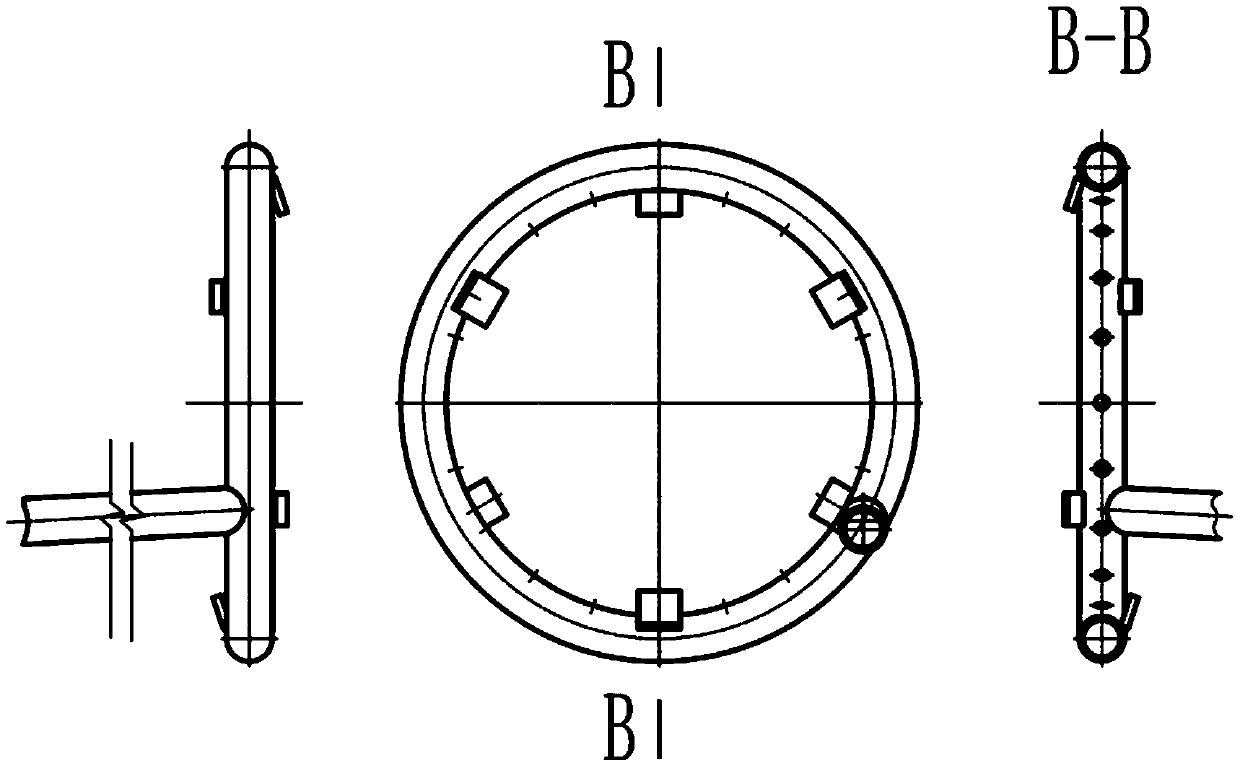

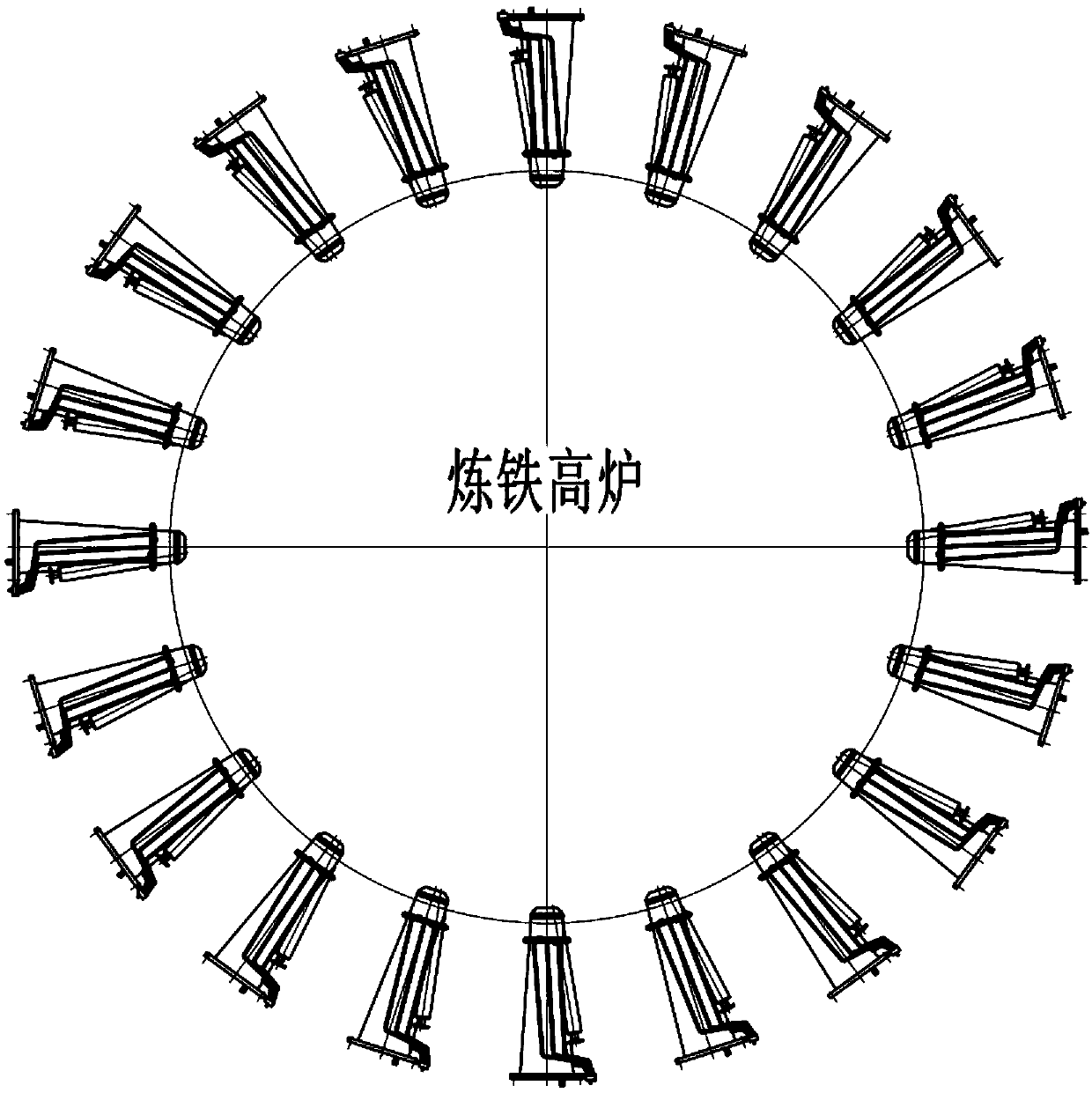

[0023] Aiming at the deficiencies of the prior art, the present invention provides a direct blowpipe of a blast furnace air supply device with a temperature alarm and automatic disposal device. By adding a temperature monitoring point at the front end of the direct blowpipe, the monitoring point can monitor the external temperature of the direct blowpipe in real time. Through this device, the working state of the straight blow pipe can be known at any time. Compared with the prior art, the present invention does not change the structure of the original straight blow pipe, and adds a thermocouple near the end of the straight blow pipe to measure the temperature at the weakest front end of the straight blow pipe. The temperature result can be fed back to the display screen in the central control room through the data line. At the same time, an air blowing device is added at the front of the straight blowing pipe, and an automatic control switch is set. After the data fed back by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com