Remote vibration monitoring system and method for eccentric main shaft of sponge cutting machine

A vibration monitoring system and technology of sponge cutting machine, applied in the field of mechanical equipment, can solve the problems of lack of remote detection of platform, serious vibration, reduced cutting speed and accuracy, etc., to achieve the effect of remote real-time monitoring and data storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the features and advantages of this patent more obvious and easy to understand, the following special examples are described in detail as follows:

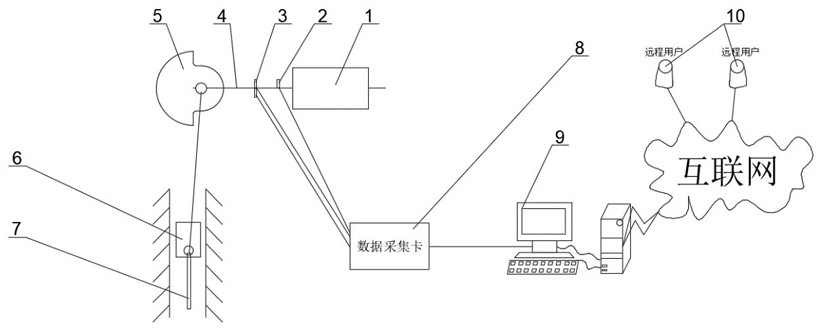

[0023] The remote intelligent vibration monitoring system of the eccentric spindle of the sponge cutting machine provided in this embodiment is as follows: figure 1 As shown, it includes: vibration sensor (eddy current displacement sensor 3), key phase sensor (photoelectric sensor 2), data acquisition card 8 and host computer (PC9). Wherein, the vibration sensor and the key phase sensor are installed on the eccentric spindle 4 of the sponge cutting machine, and are respectively connected to the data acquisition card; the data acquisition card is connected to the host computer. The host computer is connected to the remote terminal 10 through the Internet.

[0024] The principle of the sponge cutting machine is to realize the function of cutting the sponge by converting the high-speed rotating motion of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com