Environment-friendly overflow barrel equipment of drag suction dredger

A technology of trailing suction dredgers and overflow barrels, which can be used in earth movers/shovels, mechanically driven excavators/dredgers, construction, etc. Incomplete sedimentation, poor sedimentation effect and other problems, to achieve the effect of reducing suspension time, reducing air bubble content, and large immersion height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

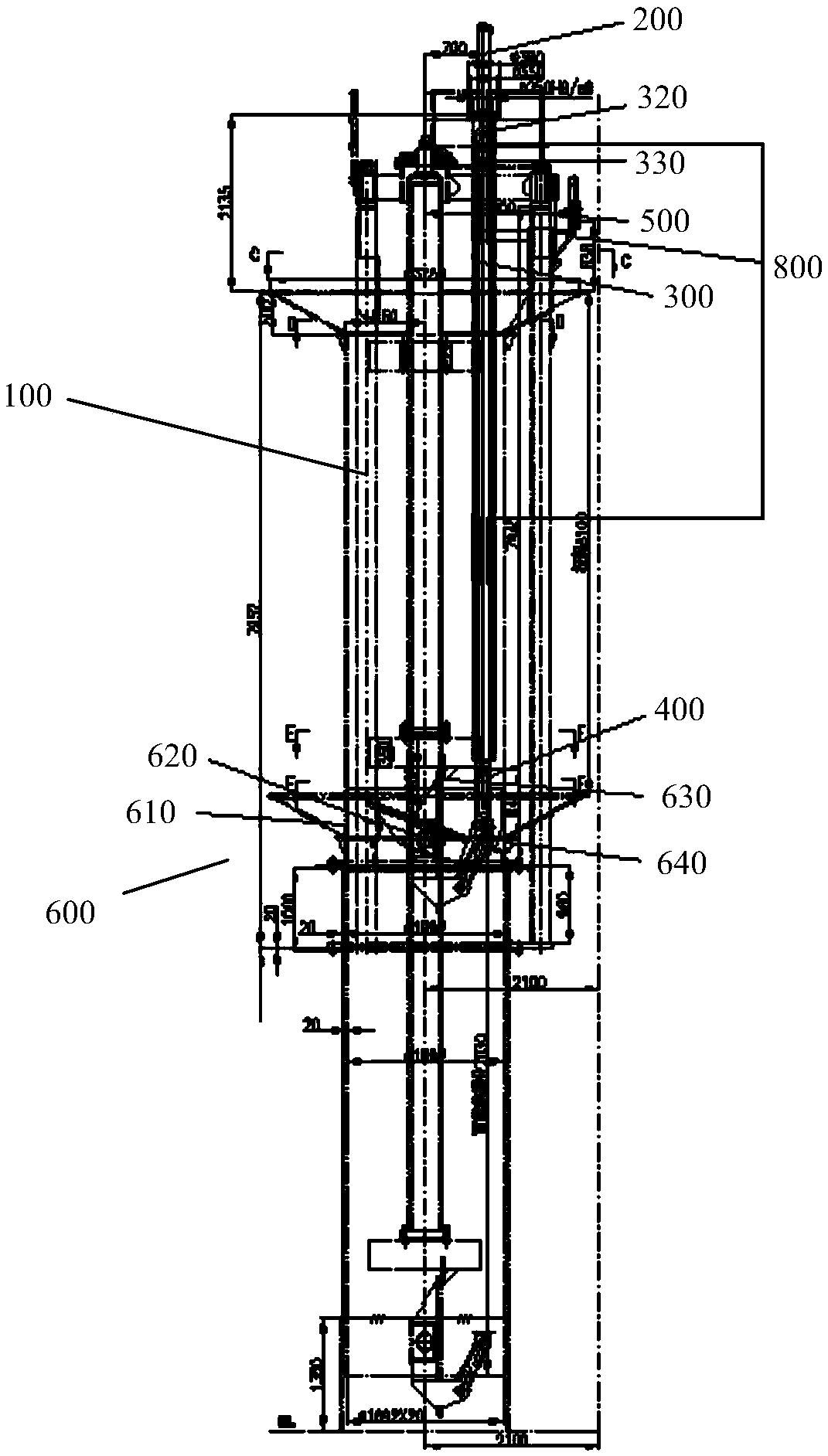

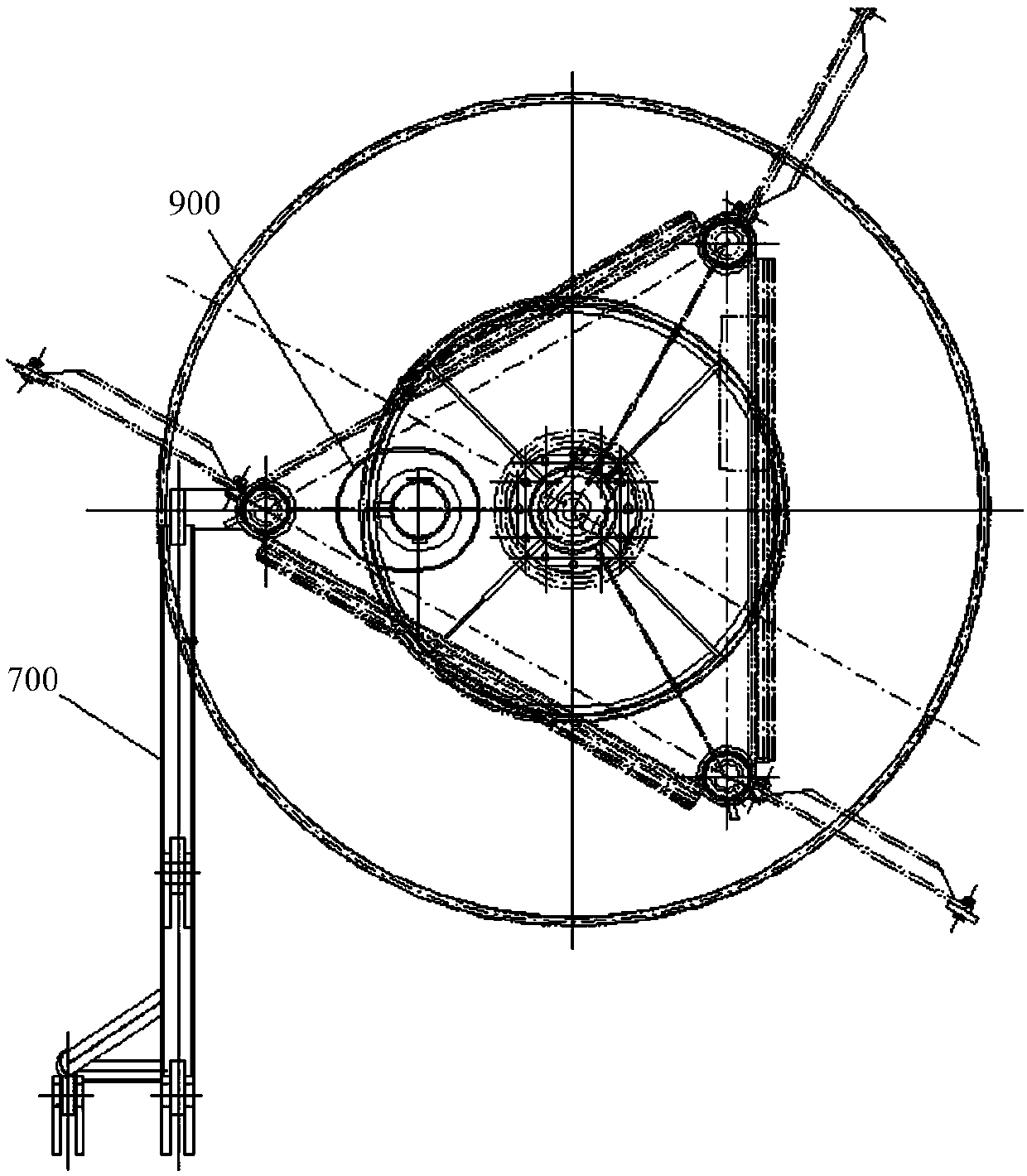

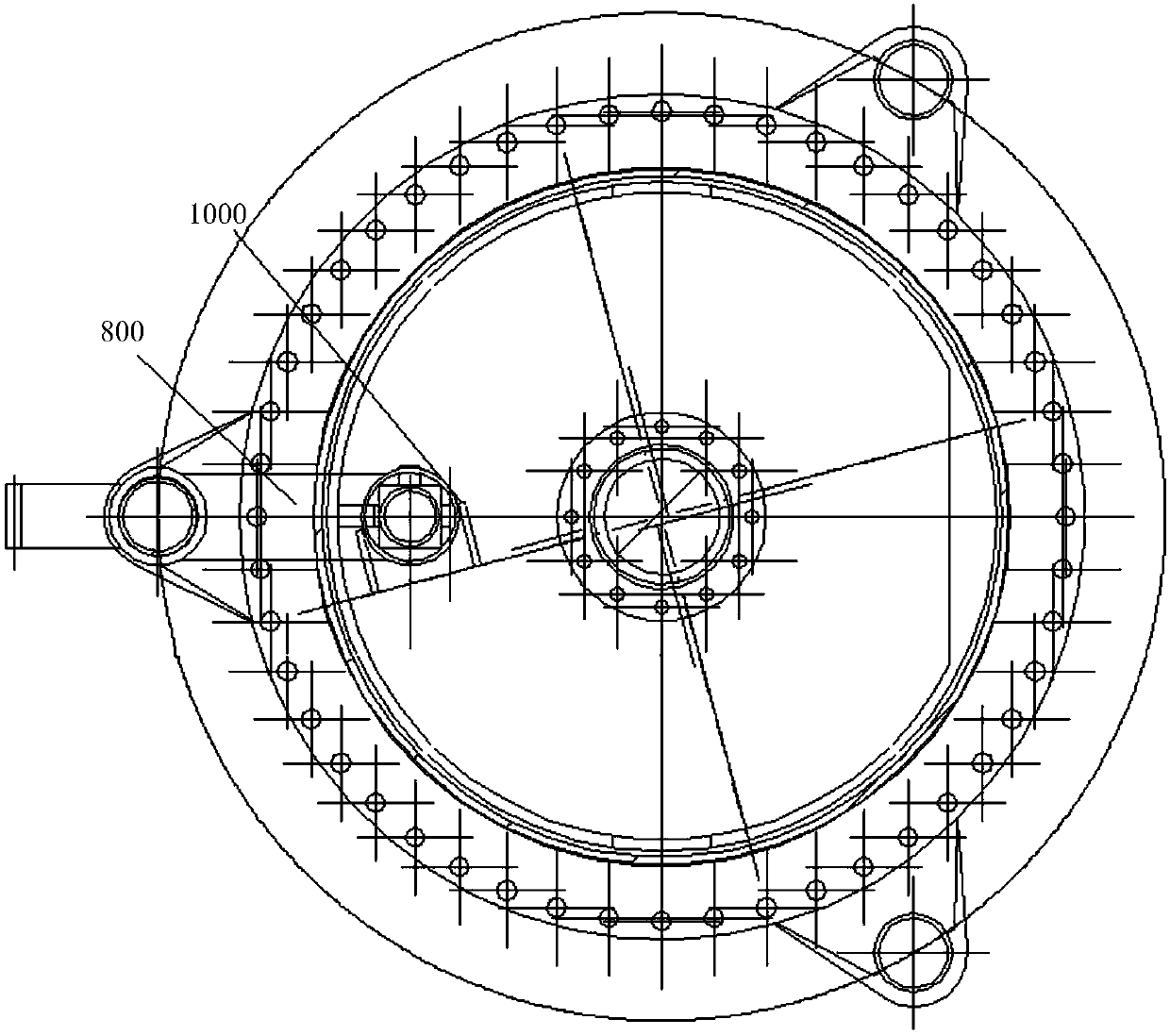

[0026] figure 1 It is a structural schematic diagram of the present invention. figure 2 It is a top view of the present invention. image 3 It is a schematic diagram of a partial structure of the top view of the present invention. Figure 4 It is a structural schematic diagram of the environmental protection valve of the present invention. Figure 5 It is a structural schematic diagram of the valve body structure of the present invention. Figure 6 It is a structural schematic diagram of the connecting rod structure of the present invention.

[0027] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the environmental protection overflow tank equipment of trailing suction dredger includes: overflow tank 100, hydraulic cylinder 200, connecting rod structure 300, intermediate connecting rod 400, sleeve structure 500, environmental protection valve 600, cable rack 700, bracket structure 800, coaming plate 900 and rib plate 1000, the hydraulic cylinder 200 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com