Installation structure and building method of cantilever scaffold bottom platform

A technology of cantilevered scaffolding and bottom platform, which is applied to the attachment of scaffolding, housing structure support, housing structure support, etc., can solve the problem of unsuitable traction force, and achieve the effect of low welding difficulty, easy installation, and uniform stress dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

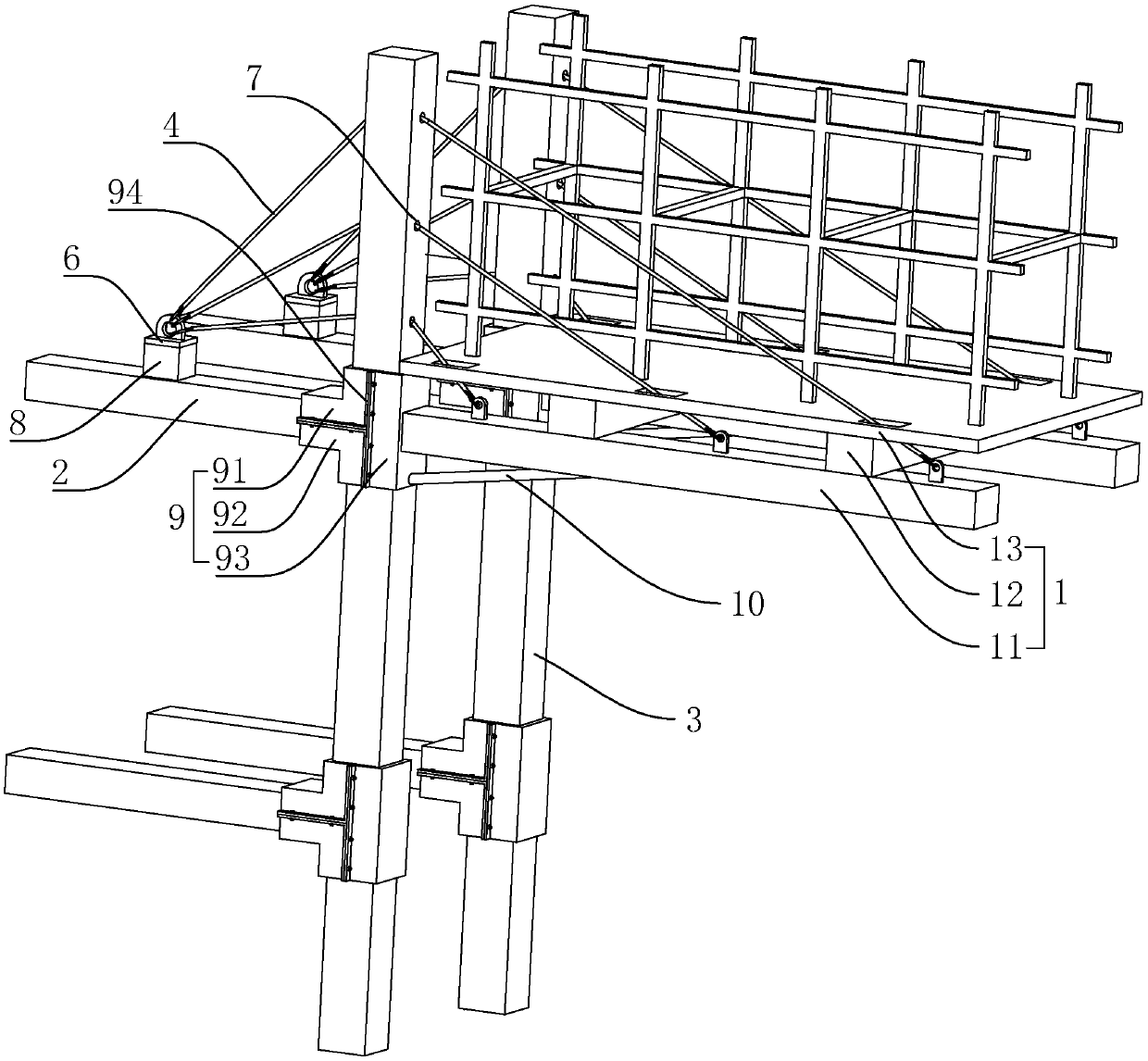

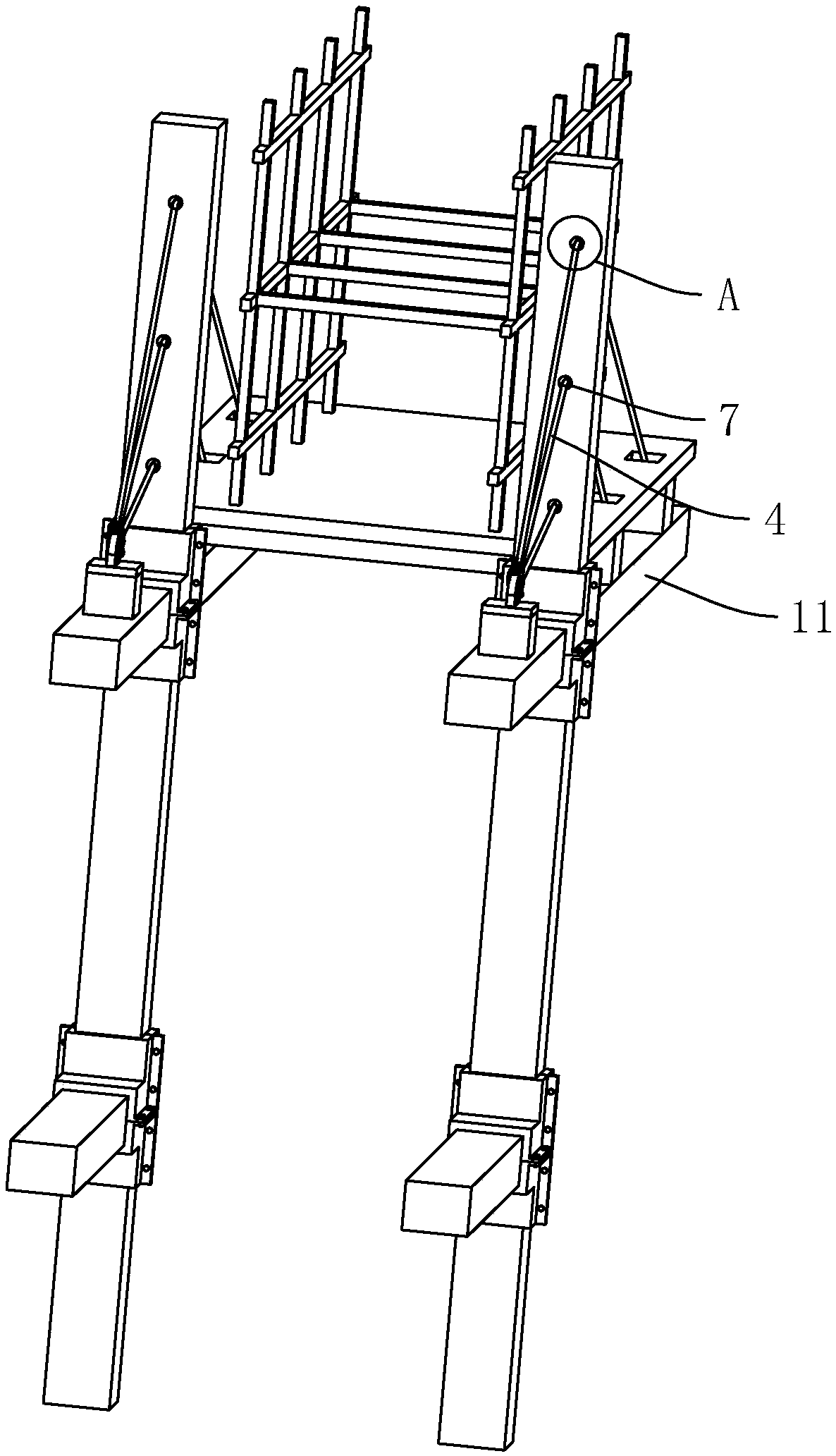

[0045] Embodiment 1: An installation structure and construction method of a platform at the bottom of a cantilevered scaffold, such as figure 1 As shown, it includes cantilevered steel 11 , horizontal support frame 12 , platform plate 13 , stay cables 4 , reserved holes 7 , supporting steel casing 9 and anchor steel plate 6 . Wherein, the stay cable 4 is related to the connection position of the cantilever shaped steel 11 and the set position of the reserved hole 7, so that the stay cable 4 can reasonably distribute the traction force to the cantilever shaped steel 11.

[0046] The horizontal support frame 12 is arranged on the top of the cantilevered steel 11, and the platform plate 13 is arranged on the horizontal support frame 12, and the platform plate 13, the horizontal support frame 12 and the cantilevered steel 11 together form the platform 1 at the bottom of the cantilevered scaffold.

[0047]The anchoring steel plate 6 is fixedly arranged on the frame beam 2 , and the...

Embodiment 2

[0054] Embodiment 2: A method for building a platform at the bottom of a cantilevered scaffold, comprising the following steps:

[0055] Step 1: making embedded parts, respectively making the first part 91, the second part 92 and the third part 93 of the supporting steel casing 9 according to the design requirements;

[0056] Step 2: Connect the embedded parts with the frame structure, install the first part 91, the second part 92 and the third part 93 of the supporting steel casing 9 to the nodes of the frame column 3 and the frame beam 2, and assemble them according to the design requirements;

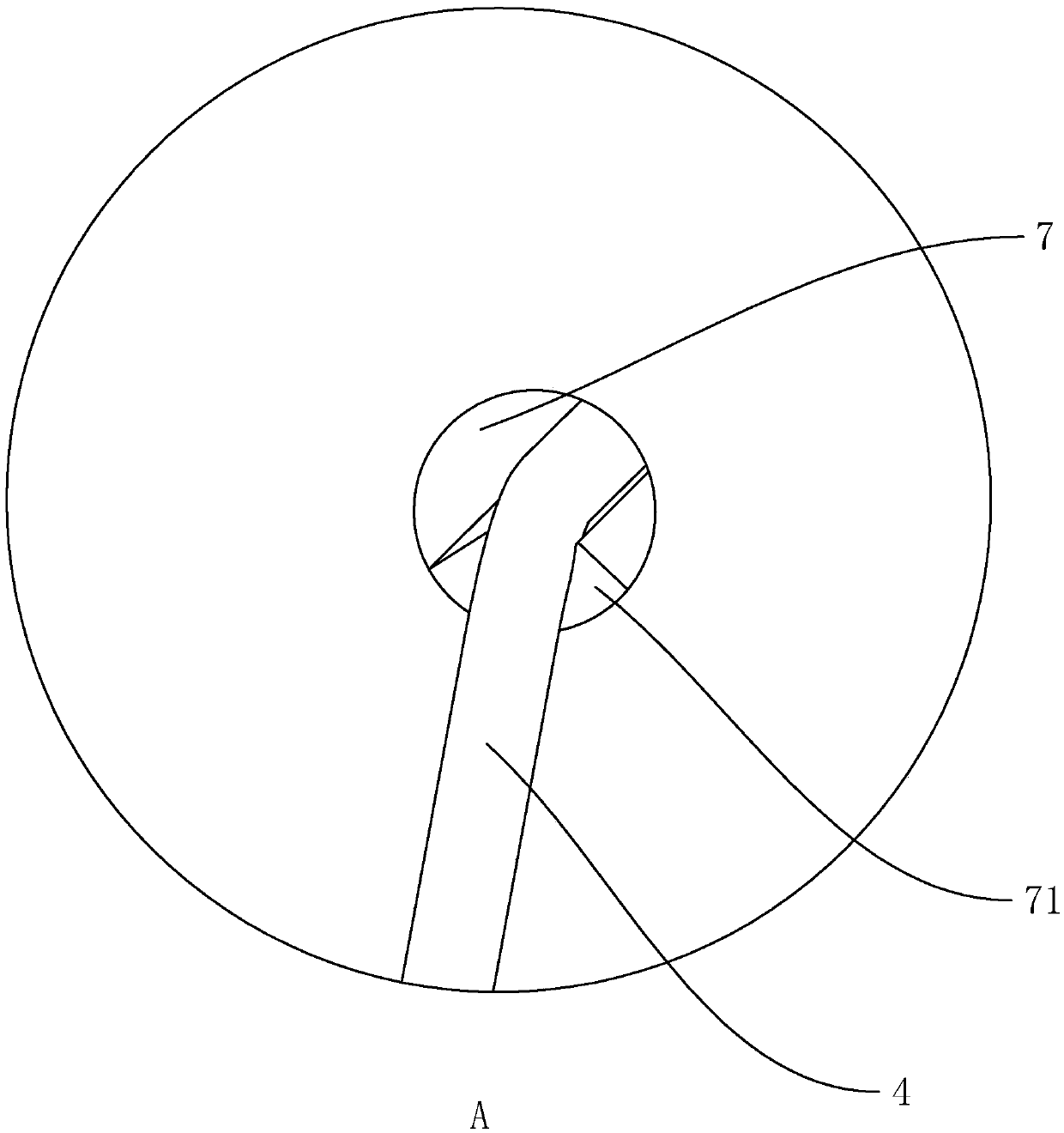

[0057] Step 3: pouring the frame structure, pouring the frame structure, and arranging the reserved holes 7 and the protection sheet 71 on the frame column 3 according to the design requirements;

[0058] Step 4: Make the supporting rods and the cantilevered steel 11, weld the end plates at the ends of the cantilevered steel 11 and the supporting inclined bar 10, and reserve bolt hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com