Early fault identification method of rolling bearing under variable rotating speed working condition

A technology of rolling bearings and recognition methods, applied to the recognition of patterns in signals, character and pattern recognition, testing of mechanical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

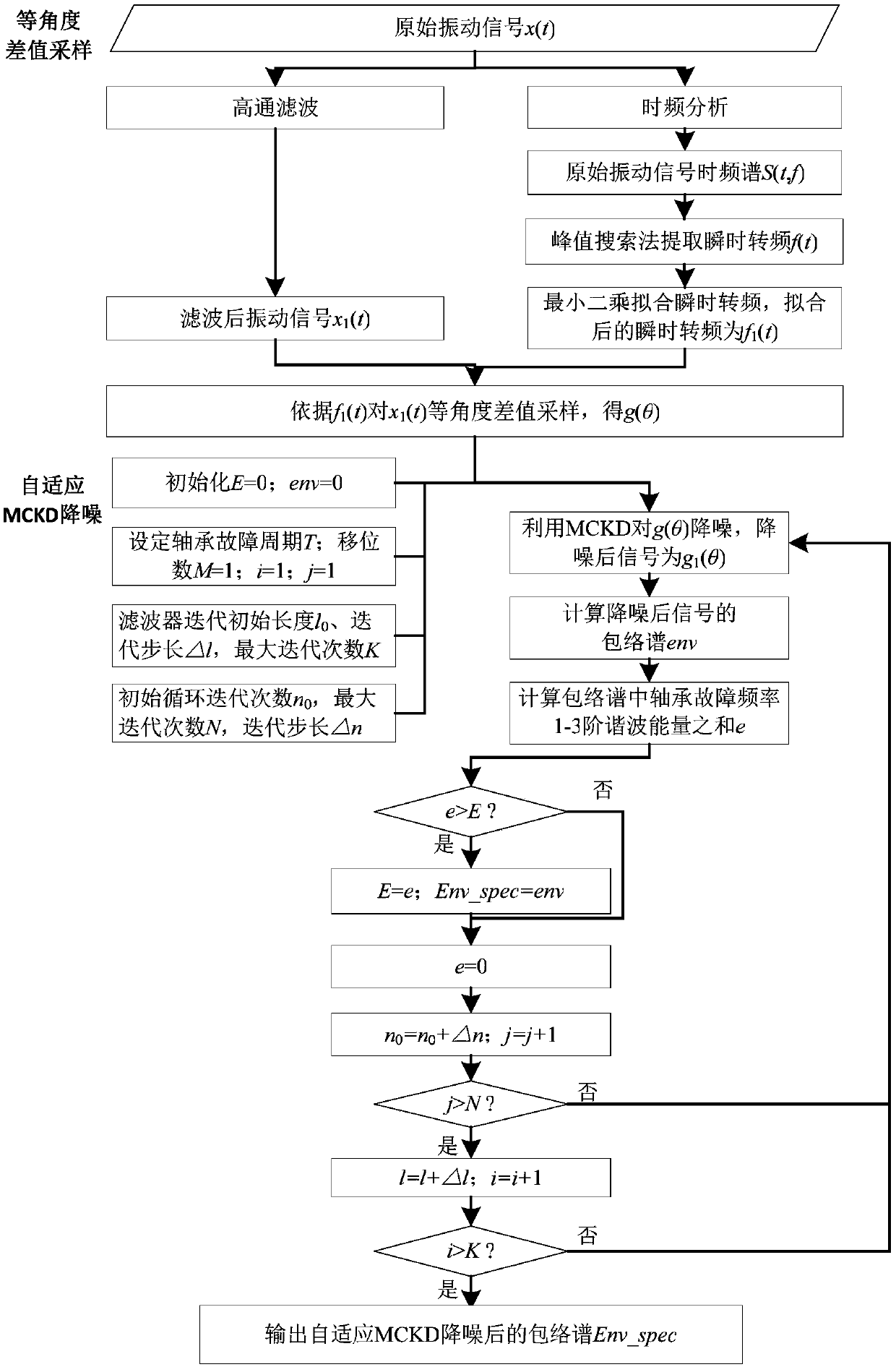

Method used

Image

Examples

Embodiment

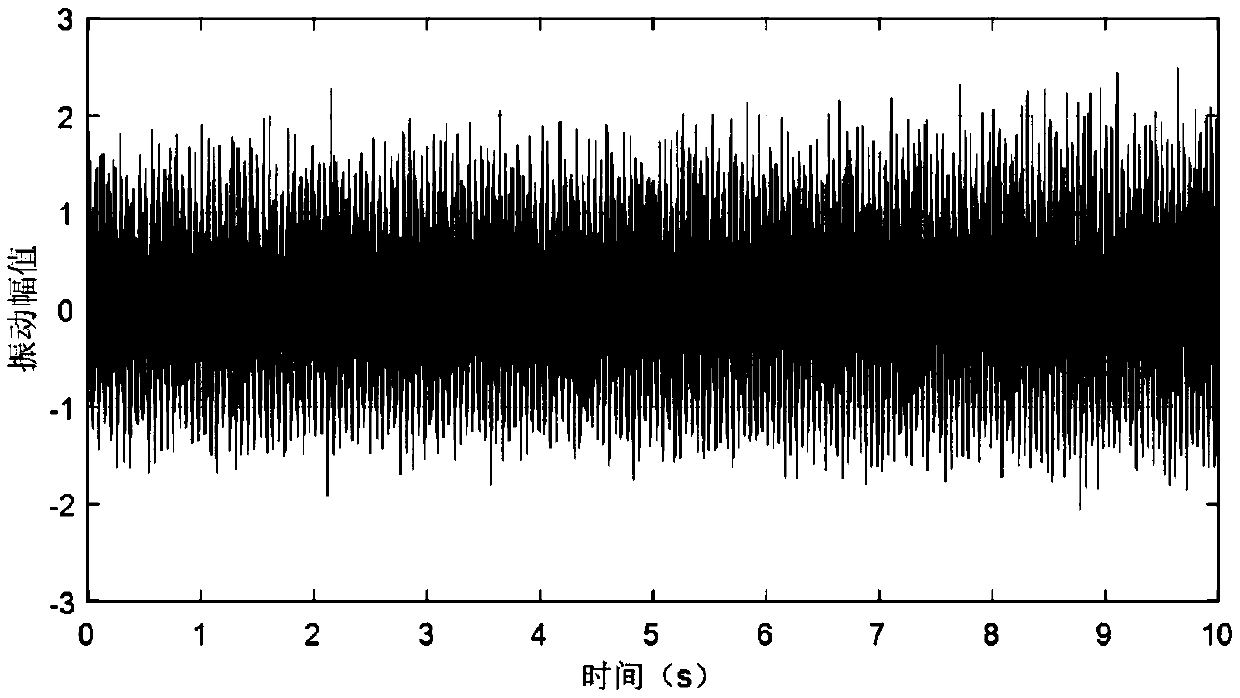

[0082] In this embodiment, the method designed in the present invention will be verified by using a set of simulation signals of rolling bearing outer ring faults under increasing speed conditions. The duration of the simulated signal is 10s, and the sampling frequency is fs=12800Hz. Under the condition of rotation frequency 1Hz, the fault characteristic frequency of bearing outer ring is 5.4Hz. The impact signal of a bearing with a single fault cycle under the condition of increasing speed is expressed as:

[0083]

[0084] a i =(T i / 10) 2 i=1,2,...,n (7)

[0085] In formula (6) and formula (7): t i is the duration of a single fault cycle; t i =a i is the shock amplitude fluctuation coefficient caused by the speed-up condition, T i is the moment corresponding to the i-th impact, and n is the number of fault cycles contained within 10s.

[0086] Combining the generated n single fault shocks can obtain the bearing outer ring fault shock signal B(t) in the whole ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com