Device and method for dynamically testing sand carrying capacity of large fracturing fluid

A technology of dynamic testing and fracturing fluid, which is applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve the problems that the sand-carrying capacity of fracturing fluid cannot be simulated, the simulation device cannot be tilted, and the fracture width cannot be realized, so as to avoid the end effect, control convenience, and the effect of enhancing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the present invention, unless stated to the contrary, "inflow end" as used generally refers to a port through which fluid flows in, and "outflow end" refers to a port through which fluid flows out.

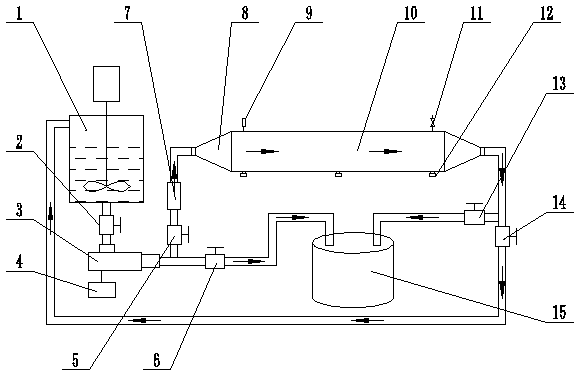

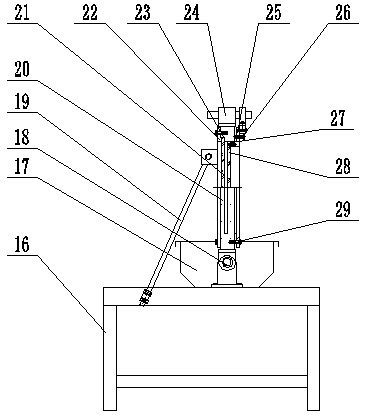

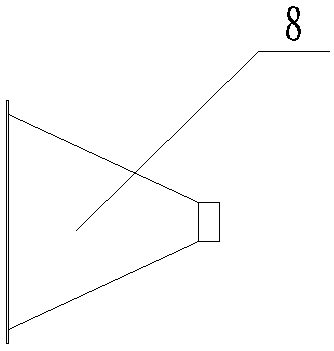

[0034] The large-scale fracturing fluid sand-carrying ability dynamic test device is composed of a mixing tank 1, a screw pump 3, a mass flow meter 7, an inlet and outlet diffuser 8, a rectangular model 10, and a slag liquid collection tank 15. The outflow end of the mixing tank 1 The inflow end of the screw pump 3 is connected through the ball valve VDa2 and the pipeline, and the outflow end of the screw pump 3 is divided into two branches, one through the ball valve VDb5, the pipeline, the mass flow meter 7, the inlet and outlet diffuser 8 and the rectangular model 10 The other is connected to the slag liquid collection tank 15 through the ball valve VDc6 and the pipeline. The screw pump 3 is provided with a frequency regulator 4, and the speed and flow are controlled b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com